A kind of anion selective separation membrane and its application

A separation membrane and selective technology, applied in the field of separation membranes, can solve the problems of complex preparation, easy detachment of the modified layer, inability to use for a long time, etc., and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

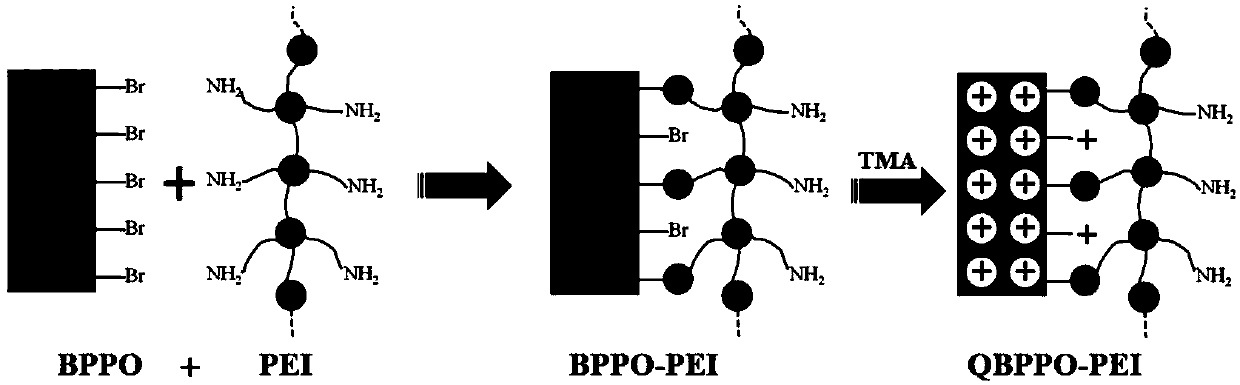

[0038] 3 g of BPPO solids with a degree of bromination of 57.8% were added to a small beaker, followed by the slow addition of 12 g of NMP. Stir magnetically until the BPPO is completely dissolved to obtain a brown transparent solution to obtain 15 ml of BPPO solution. Take a clean ordinary glass plate, pour 4ml of BPPO solution on its surface, scrape the solution quickly with a scraper with a thickness of 400 μm (the thickness of the solution is about 400 μm), and then put the glass plate on the flat heater, and the temperature of the heater is set to Set the temperature at 60°C, and set the heating time at 8 hours. After the heating, remove the BPPO film on the glass plate with a thickness of about 90 μm, and dry it for later use.

[0039] Fully soak the prepared BPPO membrane in a container filled with a 10% polyethyleneimine (PEI) aqueous solution. After reacting at room temperature for 8 hours, it was taken out, and the surface of the membrane was washed with deionized w...

Embodiment 2

[0041] The time for soaking the BPPO membrane in the above example 1 in the PEI aqueous solution with a mass concentration of 10% was changed to 16 hours, and other steps were kept unchanged to obtain a monovalent anion selective separation membrane.

Embodiment 3

[0043] The time for soaking the BPPO membrane in the above example 1 with a mass fraction of 10% PEI aqueous solution was changed to 24 hours, and other steps were kept unchanged to obtain a monovalent anion selective separation membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com