Method for refitting oil tanker into FPSO

A technology for oil tankers and oil transport platforms, applied in the field of ships, can solve problems such as collision, construction efficiency, impact of secondary coating anti-corrosion effect, damage to seawater lift pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0166] The method for refitting an oil tanker into an FPSO of the present invention includes the following refitting processes: construction and hoisting technology of multi-point mooring chain catcher-related structures, construction technology of oil delivery platform, construction technology of flare tower, hoisting technology of the upper structure of the crane and the construction process of the protective pipe of the seawater lift pump, the specific implementation methods of the above-mentioned FPSO modification processes are described below.

[0167] Construction and hoisting process related to the multi-point mooring chain stopper:

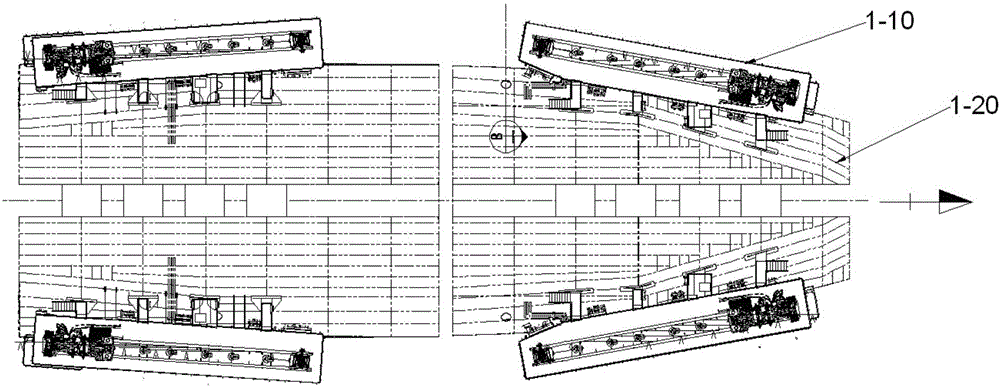

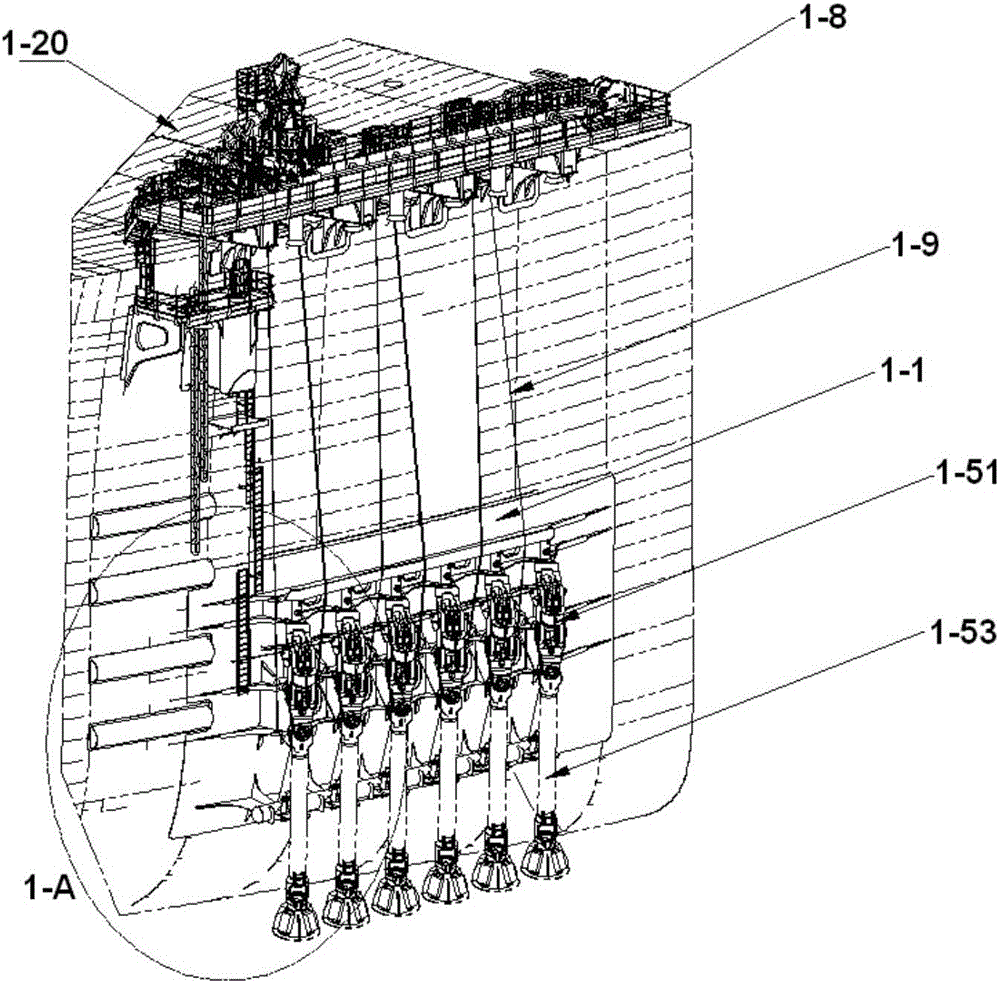

[0168] see Figure 1 to Figure 5 , figure 1 It is a flow chart of the construction of the relevant structure of the multi-point mooring chain catcher of the present invention; figure 2 It is a top view structural schematic diagram of the mooring system of the present invention; image 3 yes figure 2 A schematic diagram of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com