Preparation method and application of modified graphene oxide

A technology of stone oxide and graphene, applied to chemically modified graphene oxide, using halogenated hydrocarbons to modify graphene oxide to prepare a certain number of carbon chains on the surface, preparation, and modified graphene oxide, which can solve the preparation method conditions Harshness, poor stability of modified graphene oxide, etc., to achieve the effect of short reaction time, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

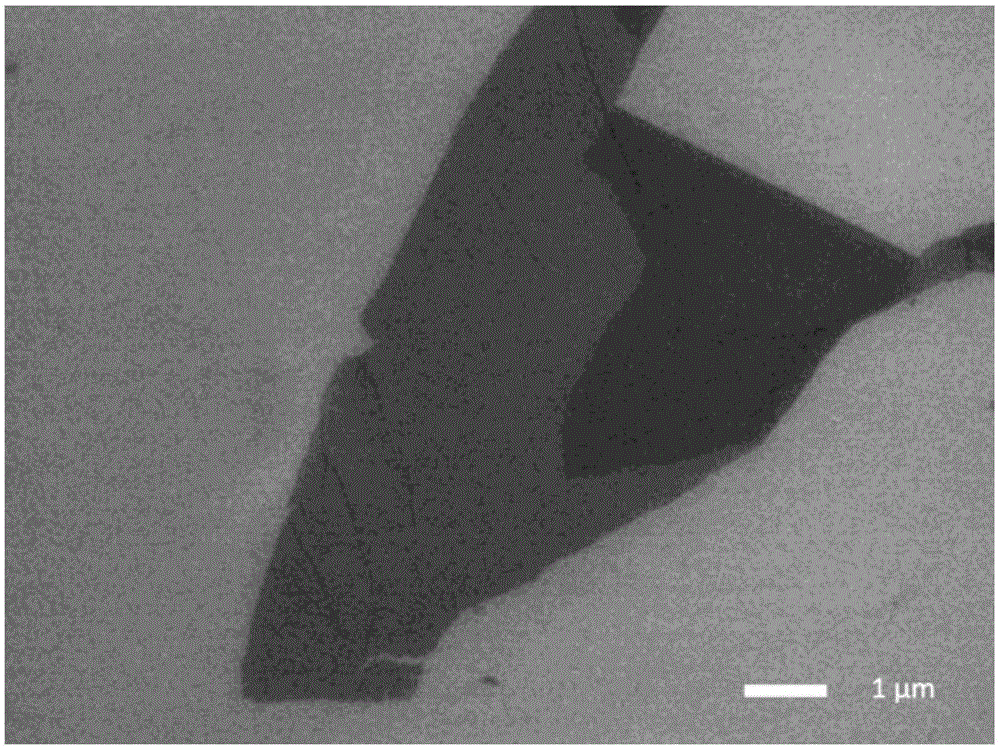

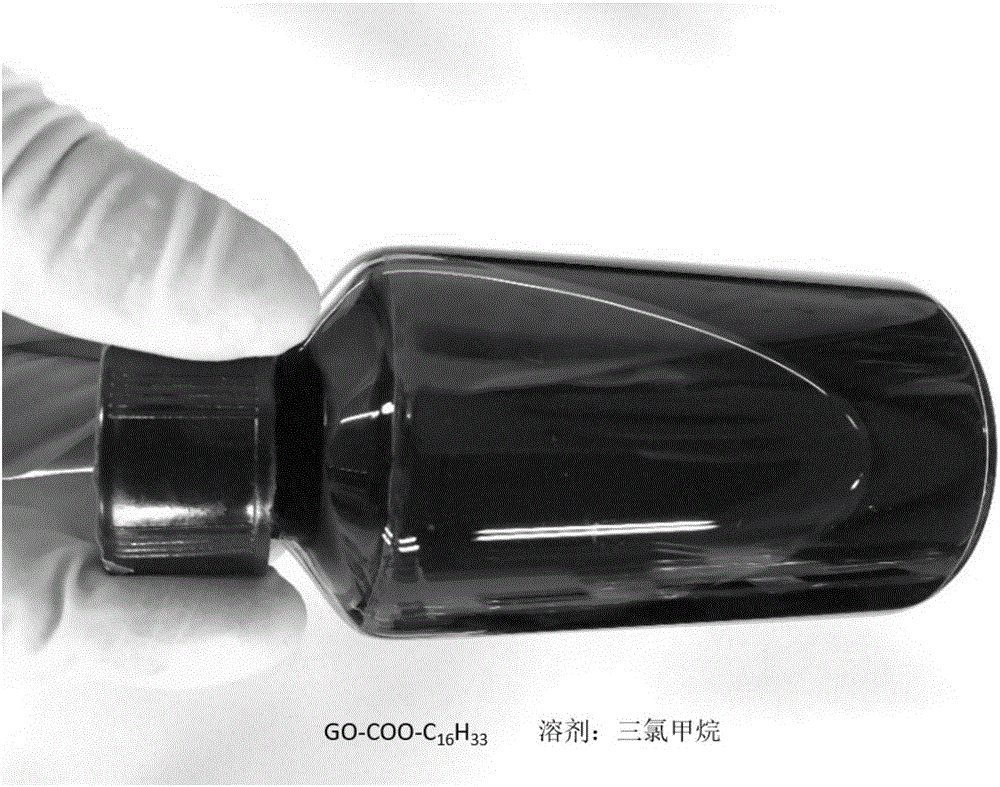

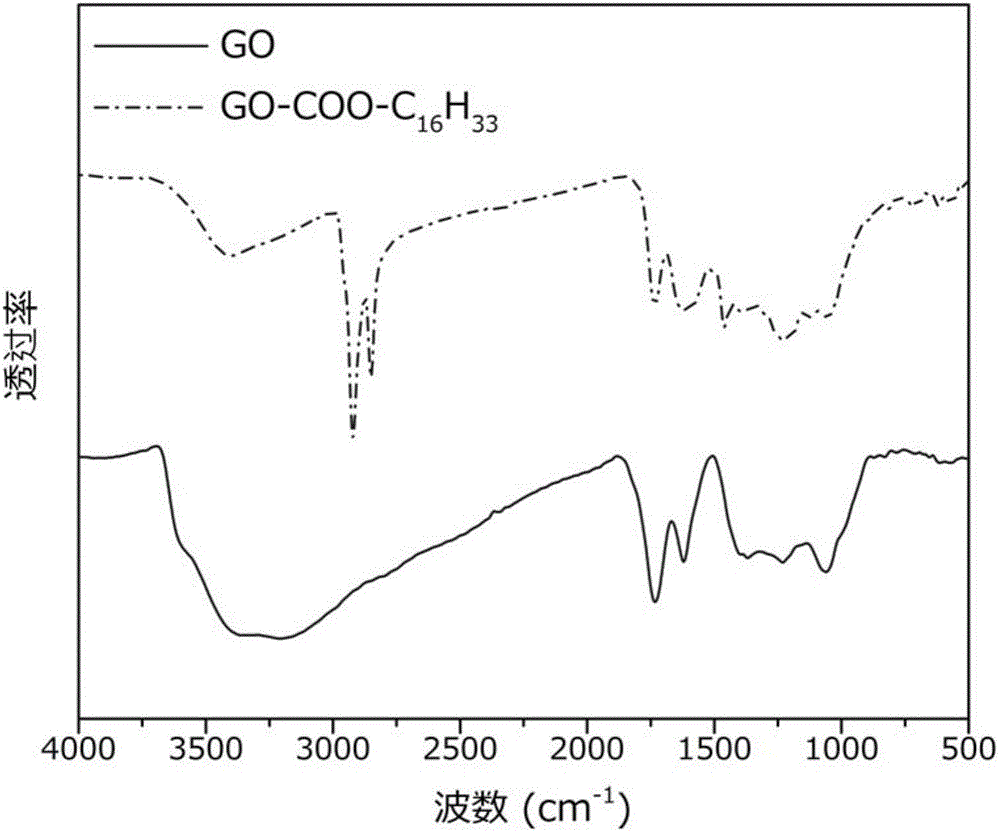

[0065]Graphene oxide was prepared by Hummers, and the prepared graphene oxide was dispersed in deionized water to prepare a 1 mg / mL dispersion. The prepared graphene oxide dispersion was mixed with sodium hydroxide solution, the concentration of sodium hydroxide solution was 1 mmol / L, and the mixed solution was sonicated for 10 min. Then add tetraoctyl ammonium bromide, the content of tetraoctyl ammonium bromide and the content ratio of graphene oxide are 2:1, then add hexadecane bromide, and its content ratio with graphene oxide is 10:1 . The homogeneously mixed mixed solution was placed in an oil bath, heated and stirred, and the temperature was kept at 100° C. for 2 h. After the reaction is complete, cool to room temperature, add 100mL of chloroform, fully shake the mixed solution and transfer it to a separatory funnel to stand still, separate the organic phase after standing, remove the insoluble matter by suction filtration, and then concentrate the mixed solution to 10m...

Embodiment 2

[0068] Graphene oxide was prepared by using Hummers, and the prepared graphene oxide was dispersed in deionized water to prepare a 1 mg / mL dispersion. The prepared graphene oxide dispersion was mixed with sodium hydroxide solution, the concentration of sodium hydroxide solution was 1 mmol / L, and the mixed solution was sonicated for 10 min. Then add tetraoctyl ammonium bromide, the content of tetraoctyl ammonium bromide and the content ratio of graphene oxide are 2:1, then add tetradecyl bromide, and its content ratio with graphene oxide is 10:1 . The homogeneously mixed mixed solution was placed in an oil bath, heated and stirred, and the temperature was kept at 100° C. for 2 h. After the reaction is complete, cool to room temperature, add 100mL of chloroform, fully shake the mixed solution and transfer it to a separatory funnel to stand still, separate the organic phase after standing, remove the insoluble matter by suction filtration, and then concentrate the mixed solution...

Embodiment 3

[0070] Graphene oxide was prepared by Hummers, and the prepared graphene oxide was dispersed in deionized water to prepare a 1 mg / mL dispersion. The prepared graphene oxide dispersion was mixed with sodium hydroxide solution, the concentration of sodium hydroxide solution was 1 mmol / L, and the mixed solution was sonicated for 10 min. Then add tetraoctyl ammonium bromide, the content of tetraoctyl ammonium bromide and the content ratio of graphene oxide are 2:1, then add dodecyl bromide, and its content ratio with graphene oxide is 10:1 . The homogeneously mixed mixed solution was placed in an oil bath, heated and stirred, and the temperature was kept at 100° C. for 2 h. After the reaction is complete, cool to room temperature, add 100mL of chloroform, fully shake the mixed solution and transfer it to a separatory funnel to stand still, separate the organic phase after standing, remove the insoluble matter by suction filtration, and then concentrate the mixed solution to 10mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com