Extraction method of lentinan

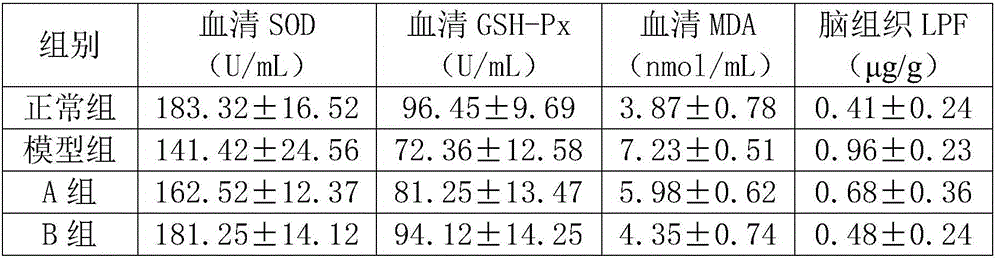

A technology of lentinan and extraction method, which is applied in the direction of anti-toxic agent, drug combination, etc., can solve the problems of hindering the development of lentinan industry, low extraction rate of lentinan, and low activity, so as to improve the total antioxidant capacity, increase the extraction rate, Improves the effect of antioxidant and anti-aging benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Take shiitake mushrooms, remove impurities and wash, drain and chop;

[0024] 2) Put the shiitake mushrooms obtained in step 1) into a high-pressure tank, add deionized water 4 times the weight of shiitake mushrooms, pressurize to 18MPa, perform high-pressure treatment for 3 minutes, and release the pressure to obtain a paste-like slurry;

[0025] 3) Add deionized water 12 times the weight of the original shiitake mushrooms to the paste slurry, then add a compound enzyme of 0.03% of the weight of the original shiitake mushrooms, adjust the pH to 5.0, and conduct ultrasonic extraction at 39° C. for 5 minutes at a frequency of 110 kHz, and then Continue to raise the temperature to 50°C for ultrasonic extraction for 10 minutes to obtain the extract, the compound enzyme is a mixture of pectin lyase, cellulase, pepsin and lipase;

[0026] 4) Suction filter the extract, compress the filtrate to 1 / 4 of the volume of the original filtrate, then add an ethanol solution with a...

Embodiment 2

[0028] 1) Take shiitake mushrooms, remove impurities and wash, drain and chop;

[0029] 2) Put the shiitake mushrooms obtained in step 1) into a high-pressure tank, add deionized water 5 times the weight of shiitake mushrooms, pressurize to 16MPa, perform high-pressure treatment for 5 minutes, and release the pressure to obtain a paste-like slurry;

[0030] 3) Add deionized water 10 times the weight of the original shiitake mushrooms to the paste slurry, then add a compound enzyme of 0.05% of the weight of the original shiitake mushrooms, adjust the pH to 4.8, and conduct ultrasonic extraction at 39° C. for 6 minutes at a frequency of 130 kHz, and then Continue to raise the temperature to 49°C for ultrasonic extraction for 9 minutes to obtain the extract, and the compound enzyme is a mixture of pectin lyase, cellulase, pepsin and lipase;

[0031] 4) Suction filter the extract, compress the filtrate to 1 / 3 of the volume of the original filtrate, then add 13 times the weight of ...

Embodiment 3

[0033] 1) Take shiitake mushrooms, remove impurities and wash, drain and chop;

[0034] 2) Put the shiitake mushrooms obtained in step 1) into a high-pressure tank, add deionized water 6 times the weight of shiitake mushrooms, pressurize to 14MPa, perform high-pressure treatment for 7 minutes, and release the pressure to obtain a paste-like slurry;

[0035] 3) Add deionized water 9 times the weight of the original shiitake mushrooms to the paste slurry, then add a compound enzyme of 0.07% of the weight of the original shiitake mushrooms, adjust the pH to 4.5, and conduct ultrasonic extraction at 38° C. for 8 minutes at a frequency of 150 kHz, and then Continue to raise the temperature to 48°C for ultrasonic extraction for 8 minutes to obtain the extract, and the compound enzyme is a mixture of pectin lyase, cellulase, pepsin and lipase;

[0036] 4) Suction filter the extract, compress the filtrate to 1 / 4 of the volume of the original filtrate, add 15 times the weight of the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com