High-resilience aging-resistant EVA foamed material and preparation method thereof

A foaming material, anti-aging technology, used in applications, shoe soles, clothing and other directions, can solve the problems of large thermal shrinkage, easy deformation, odor and unpleasant, and achieve the effect of light weight, good elasticity and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

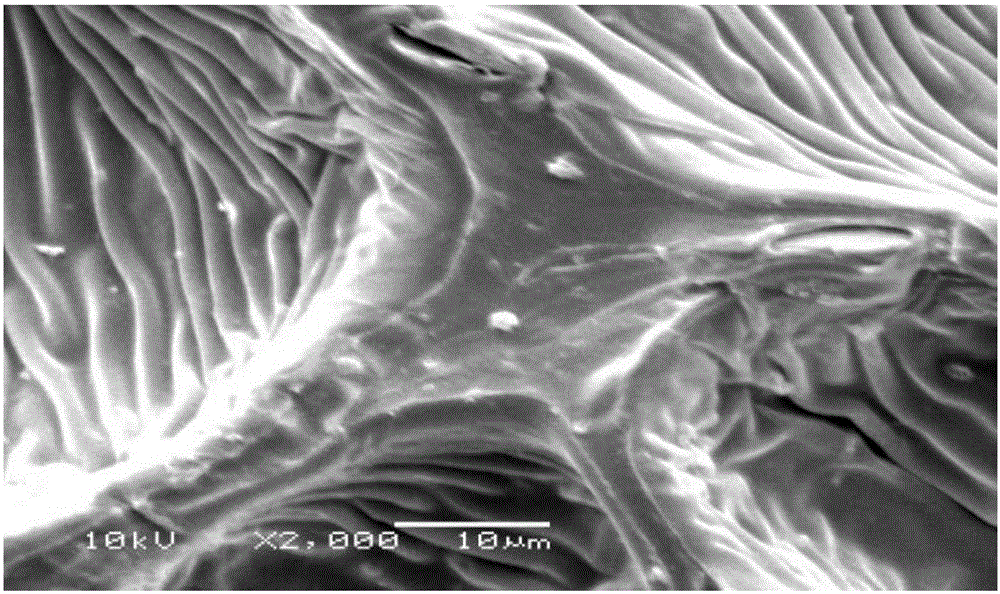

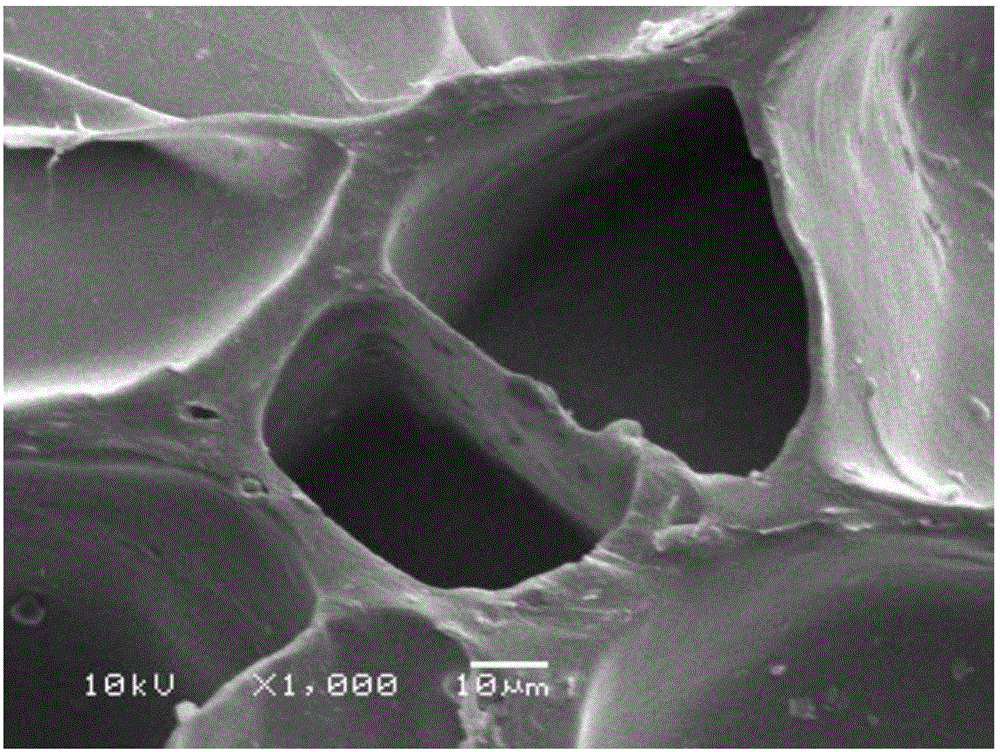

[0032] Embodiment 1, preparation modified lignocellulose powder foam body

[0033] 50 parts by weight of lignocellulose powder with a particle size of 500 meshes are uniformly sprayed with 5 parts by weight of silane coupling agent, stored and dried to prepare uniform modified lignocellulose powder.

[0034] The trade name EVA7470 of 50 parts by weight, the ethylene-vinyl acetate copolymer (wherein the mass percent composition of vinyl acetate (VA) is 26%), the trade name GT-01 of 50 parts by weight, number average molecular weight is 1800, Number-average molecular weight is that the partially hydrogenated styrene-butadiene polymer of 20000 and the particle diameter of 50 parts by weight are 500 purpose modified lignocellulose powders and put into internal mixer and mix, and in the process of mixing, the temperature of open mixer is not constant. If it exceeds 70°C, the kneading temperature is 90°C, and the kneading time is 0.2 hours.

[0035] Simultaneously with the whipping...

Embodiment 2-7

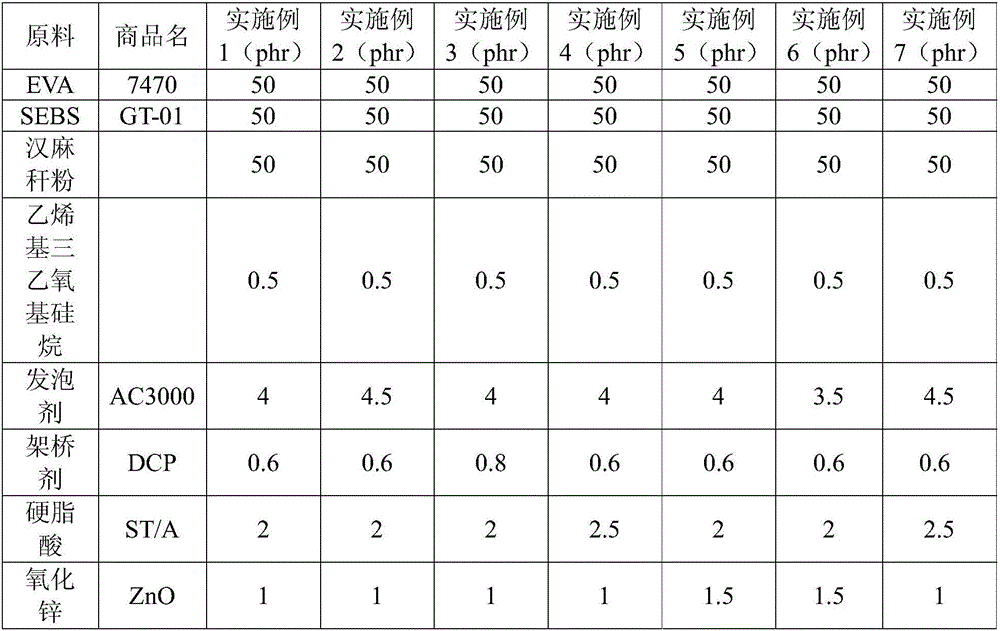

[0040] Example 2-7, preparation of modified lignocellulose powder foam

[0041] Following the same steps as in Example 1, only the components were replaced according to the parts by weight listed in Table 1, to obtain the modified lignocellulose powder foam prepared in Examples 2-7.

[0042] Table 1, the list of parts by weight of each raw material in the modified lignocellulose powder foam prepared in Examples 1-7

[0043]

Embodiment 3

[0044] Embodiment 3, performance test of modified lignocellulose powder foam body

[0045] The physical properties of the lignocellulose powder foams prepared in Examples 1-7 are shown in Table 2.

[0046] In Table 2, the test methods for each indicator are as follows:

[0047] Apparent density: HG / T 2872-2009, test piece with leather;

[0048]Tensile strength: GB / T 10654-2001, the test piece with skin, the distance between the marking lines is 50mm, take the average value of the test results in two vertical directions;

[0049] Elongation at break: GB / T 10654-2001, the test piece with skin, the distance between the marking lines is 50mm, and the average value of the test results in two vertical directions is taken;

[0050] Right-angle tear strength: GB / T 10808-2006, test piece with leather, test speed 50mm / min;

[0051] Resilience: GB / T 10652-2001, test piece with leather;

[0052] Peel strength of sole circumference after humidified aging: GB / T 3903.7-2005, Appendix E.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com