La-mg-ni series hydrogen storage alloy for nickel-hydrogen battery and preparation method thereof

A technology for hydrogen storage alloys and nickel-metal hydride batteries, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problem that it is difficult to further improve the stability of charge and discharge cycles, and achieve improved electrochemical kinetics and cycle stability performance, The effect of high maximum discharge capacity, good kinetic performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

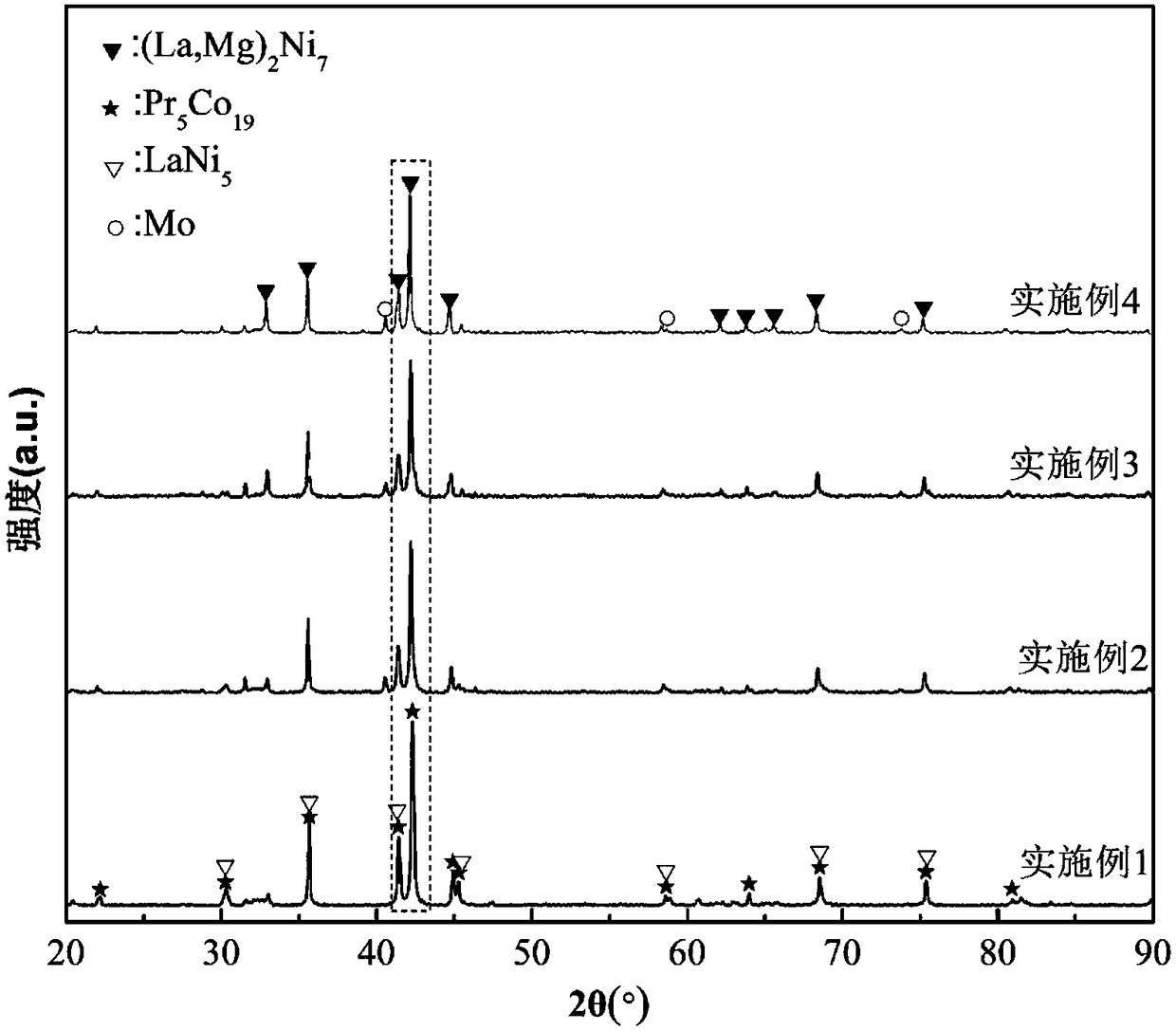

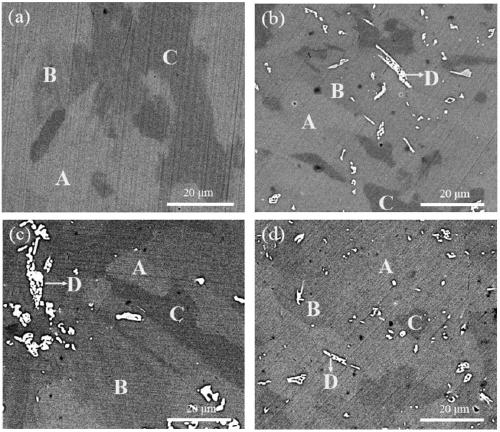

[0030] See Table 1 for the components and contents of the alloys in Examples 1-4. Table 1 shows the theoretical formulation of the alloy, the actual values for compensating for the volatilization of lanthanum and magnesium, and the representative formula of the alloy.

[0031] The specific preparation method is as follows:

[0032](1) Ingredients: Commercial high-purity metal raw materials are used, which are respectively 99.5% pure lanthanum (La) block, 99.94% pure magnesium ingot (Mg), 99.96% pure electrolytic nickel (Ni) block, 99.95% pure Pure cobalt flakes (Co), 99.5% aluminum bulk (Al) and 99% molybdenum grains (Mo). Prepare materials according to the contents in Table 1; cut the magnesium ingot into small pieces of magnesium, wherein the size of the small pieces of magnesium (length×width×height) is less than 2×2×1cm.

[0033] (2) Melting: Put the materials prepared in step (1) into the alumina crucible in a certain order, wherein molybdenum particles and nickel are ...

Embodiment 5

[0074] In Examples 5-7, except that the annealing temperature is different from that of Example 3, the process parameters for preparing other alloys and the testing methods of alloy electrode performance are the same as those of Example 3, wherein the annealing temperature of Example 5 is 800°C, and the method of Example 6 is The annealing temperature in Example 7 was 850°C, and the annealing temperature in Example 7 was 950°C. The electrochemical properties of the obtained alloy electrodes are shown in Table 3 below.

[0075] The electrochemical performance data of table 3 embodiment 5-7 alloy electrode

[0076]

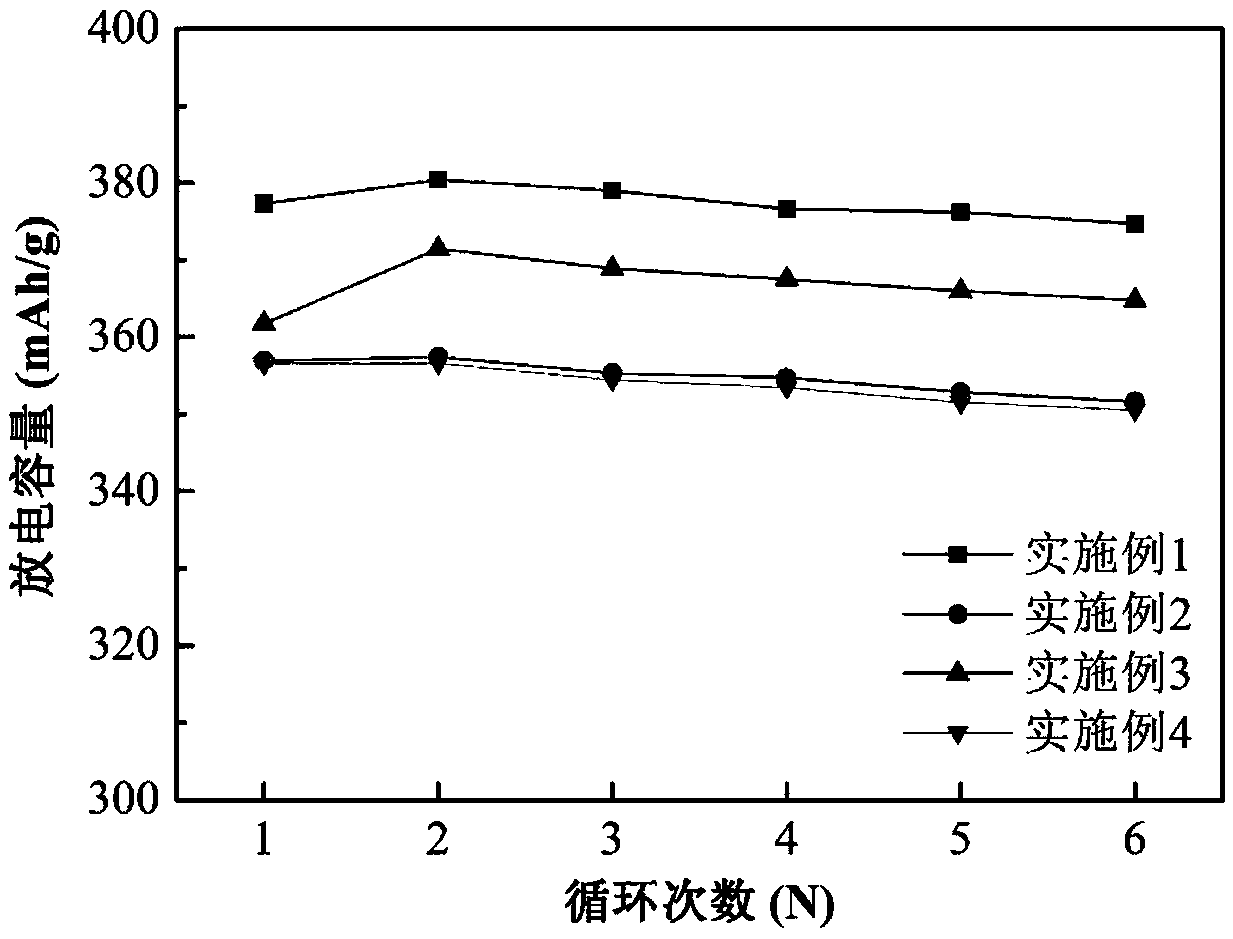

[0077] Considering the electrochemical properties of Examples 1-7, Example 3 is the annealed 900°C*8h alloy electrode La 0.75 Mg 0.25 Ni 3.05 co 0.20 al 0.10 Mo 0.15 While maintaining a high discharge capacity, the cycle stability and high-rate discharge performance of the alloy electrode are also greatly improved, so it has the best comprehensive electroche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com