All-round collecting and discharging system for smoke liquid-state media

A technology of liquid medium and discharge system, applied in the field of flue gas liquid medium all-round collection and discharge system, can solve the problem of inability to collect chimney acid liquid, corrosion of the inner wall of the chimney, failure to solve the corrosion and leakage of the inner wall of the chimney and the corbel, etc. problems, to achieve the effect of solving chimney leakage and alleviating chimney rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

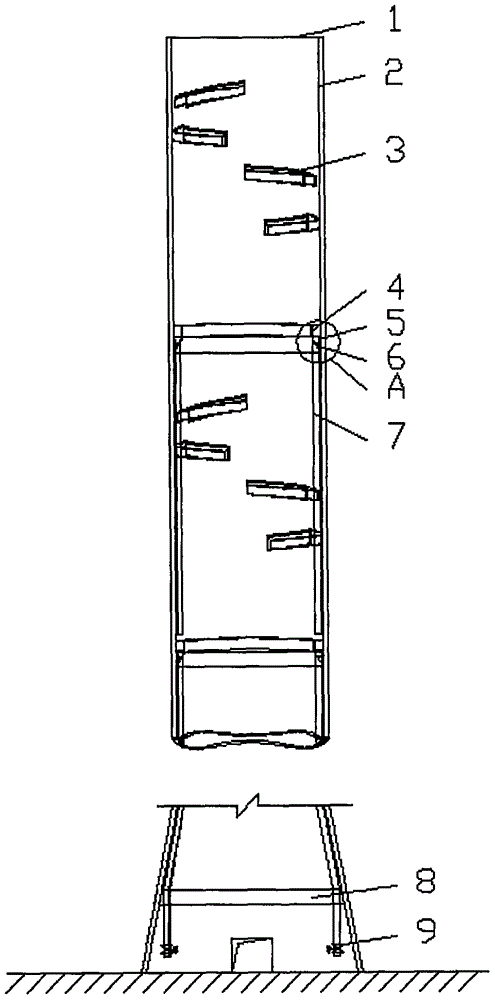

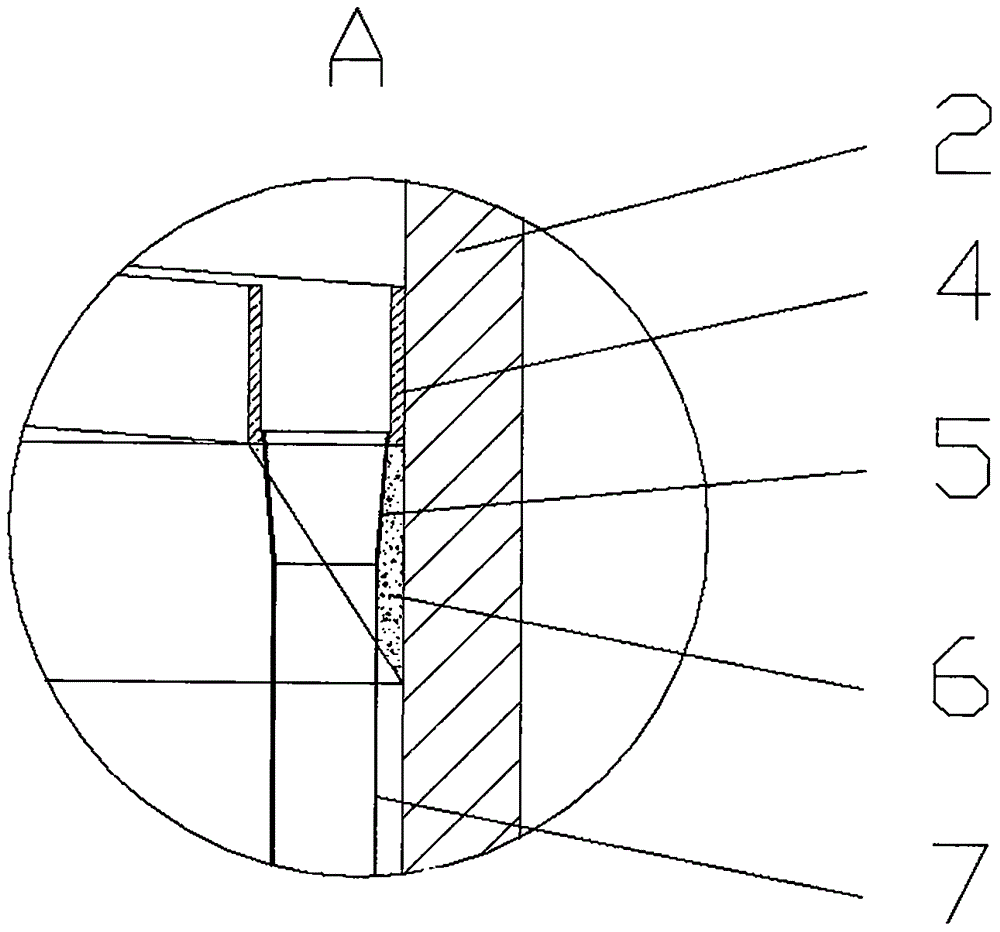

[0026] The present invention will be described in more detail below in conjunction with the accompanying drawings, but it does not constitute any limitation to the present invention.

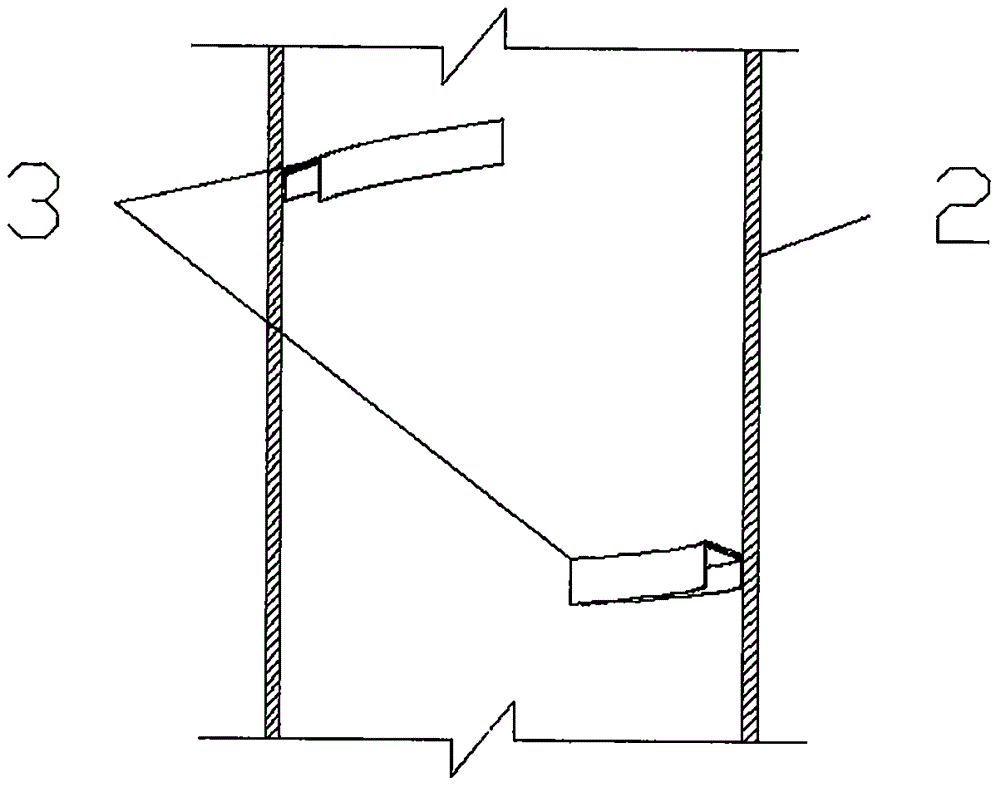

[0027] An all-purpose collection and discharge system for flue gas liquid medium, which is composed of an active collection device, a passive collection device and an acid discharge device. The quantity of described active collection device, passive collection device and glass fiber reinforced plastics acid discharge pipeline 7 is determined according to the quantity of corbel 6 above the ash accumulation platform in the chimney, and a corbel 6 corresponds to a set of collection and discharge device; the chimney without corbel 6 can The number of collection and discharge devices is determined according to the content of condensed acid in the chimney.

[0028] A set of active collection device is composed of 4 inverted special-shaped glass fiber reinforced plastic U-shaped grooves 3, the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com