Combustion control device for utility boiler and method of use thereof

A technology for control devices and power plant boilers, which is applied in the direction of controlling combustion, lighting and heating equipment, etc. It can solve the problems of not being able to obtain the quality changes of the coal in the boiler in time, so as to avoid combustion deterioration, reduce the number of cleaning times, and prevent boiler coking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

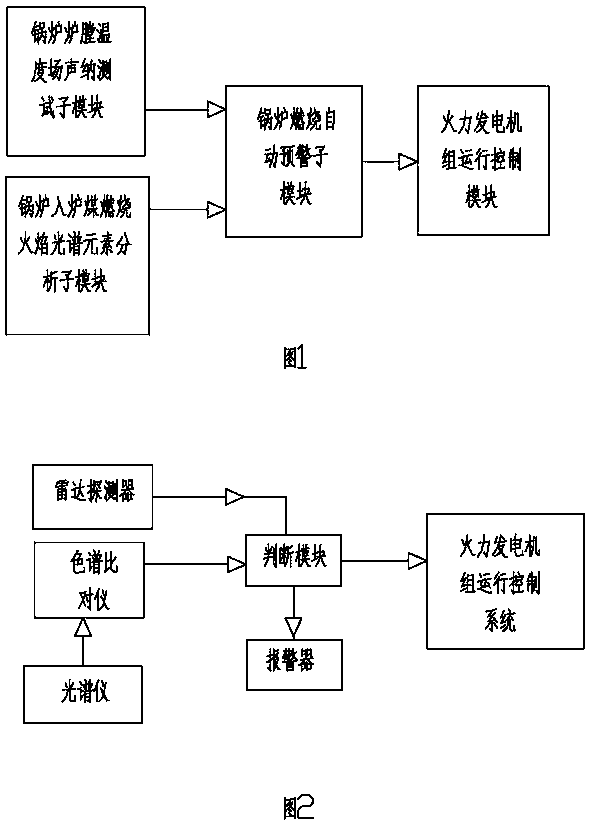

[0019] Embodiment 1: as attached figure 1 As shown, the power station boiler combustion control device includes the boiler furnace temperature field sonar test sub-module, the boiler furnace coal combustion flame spectrum element analysis sub-module, the boiler combustion automatic warning sub-module and the thermal power generation unit operation control module, the boiler furnace temperature The signal output end of the field sonar test sub-module is electrically connected to the first signal input end of the boiler combustion automatic warning sub-module, and the signal output end of the boiler coal combustion flame spectrum element analysis sub-module is connected to the first signal input end of the boiler combustion automatic warning sub-module. The two signal input ends are electrically connected, and the signal output end of the boiler combustion automatic warning sub-module is electrically connected with the signal input end of the thermal power generation unit operati...

Embodiment 2

[0025] Embodiment 2: as attached figure 1 As shown, the method of using the power plant boiler combustion control device is carried out as follows: use the boiler furnace temperature field sonar test sub-module to collect the temperature data on the boiler furnace section, and use the boiler furnace coal combustion flame spectrum element analysis sub-module Obtain the elemental spectrum analysis data of the combustion flame of the pulverized coal in the burner area of the boiler. Then, the sonar test sub-module of the boiler furnace temperature field sends the temperature data to the boiler combustion automatic warning sub-module, and the combustion flame spectrum element analysis sub-module of the boiler enters the furnace The module sends the element spectrum analysis data to the boiler combustion automatic warning sub-module, and the temperature data is compared with the standard temperature set by the boiler combustion automatic warning sub-module to obtain the temperatur...

Embodiment 3

[0026] Embodiment 3: as attached figure 2As shown, as the optimization of embodiment 2, the use method of the power plant boiler combustion control device is carried out as follows: the sound wave probe of the radar detector is fixedly installed on the water wall of the boiler, and the sound wave probe of the radar detector collects the boiler furnace For the temperature data on the section, the spectrometer is used to collect the light intensity of the pulverized coal combustion flame in the burner area of the boiler. The spectrometer converts the collected light intensity into corresponding flame spectral data, and the spectrometer sends the flame spectral data to the chromatographic comparison instrument. The flame spectrum data is processed by the chromatographic comparator to obtain the element spectrum analysis data. Then, the radar detector sends the collected temperature data to the judgment module, and the temperature data is compared with the standard temperature s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com