Electric heating furnace

A technology for electric heating furnaces and heating elements, which is applied in the field of household or commercial electric heating stoves and electric heating products, and can solve the inconvenience of integration or online operation of related supporting equipment, inflexible combination of large and small furnace chambers or different types of furnace chambers , high-voltage power supply is inconvenient to control separately, etc., to achieve the effect of easy automatic cooking operation, small footprint and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

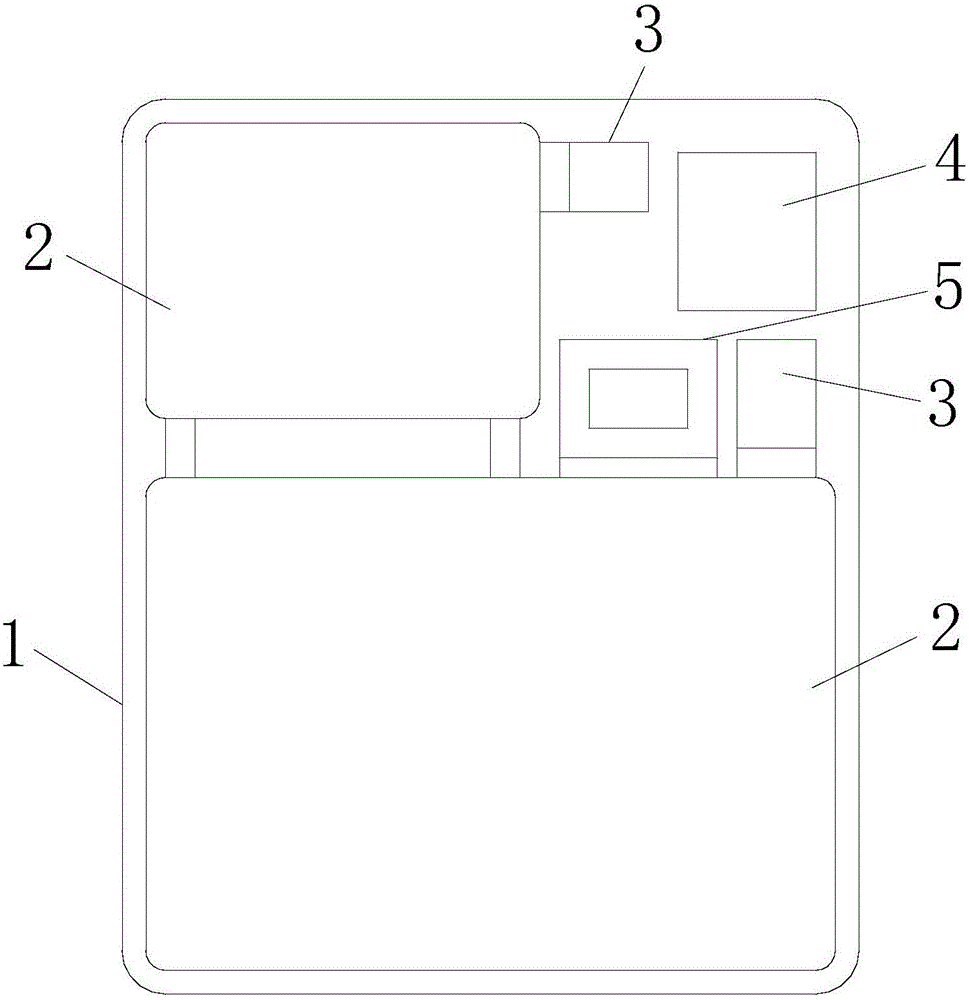

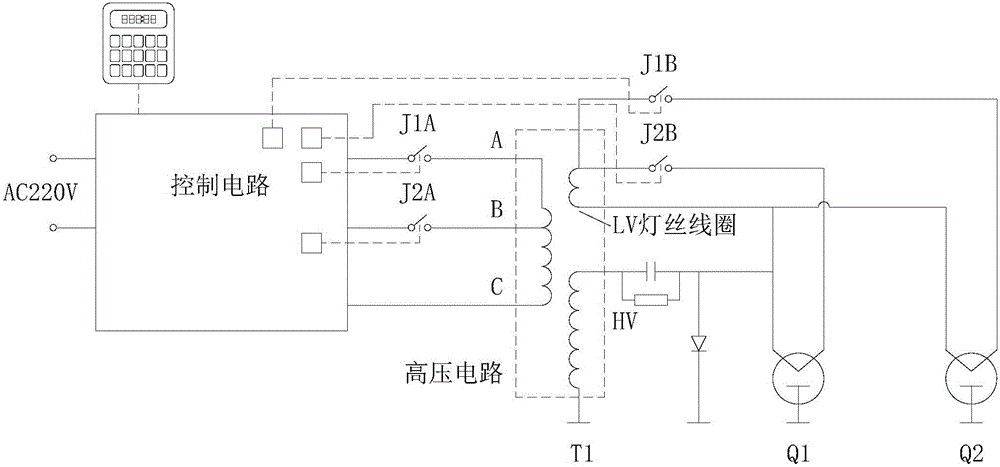

[0038] Example 1: Please refer to figure 1 , figure 2 with image 3 As shown, the present invention provides an electric heating stove, preferably, the electric heating stove is a microwave oven, which includes:

[0039] Furnace body 1, which has at least two furnace chambers 2;

[0040] At least two heating elements 3, the heating elements 3 are magnetrons, and each heating element 3 corresponds to heating food in different oven chambers 2;

[0041] A control circuit 4, the input end of which is connected to the mains power supply, and the output end of the control circuit 4 is connected to the high-voltage circuit 5;

[0042] For the microwave oven, the high-voltage circuit 5 is used as a supporting circuit for the control circuit 4, and its input terminal is connected to the output terminal of the control circuit 4;

[0043] A plurality of switching elements, the control end of each heating element 3 is respectively connected to the output end of the high voltage circu...

Embodiment 2

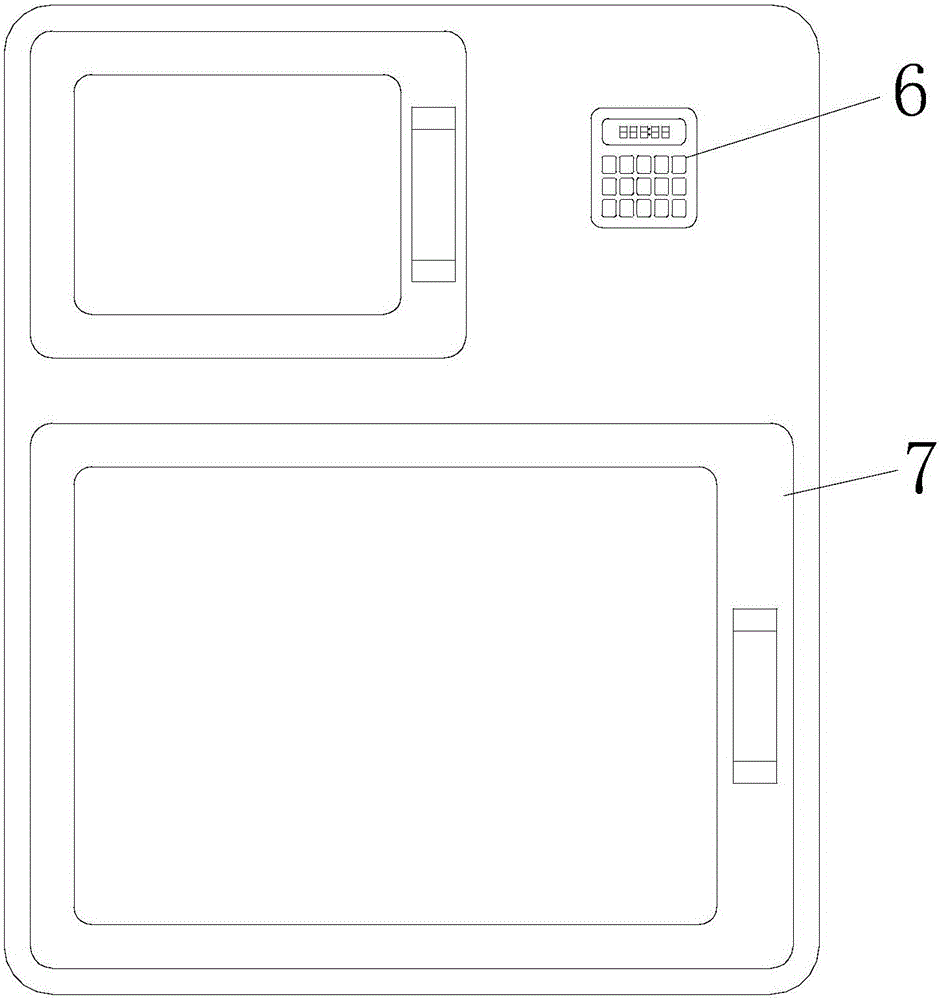

[0056] Example 2: Please refer to Figure 4 , Figure 5 with Image 6 As shown, the present invention provides a microwave oven with three chambers, which is suitable for multiple food heating at the same time, such as pancake heating and other applications. Its corresponding circuit schematic diagram is as follows Image 6 As shown, a relay J3B can be added to the end of the LV filament coil for control, and one tap for voltage regulation can be reserved for the primary coil of the transformer, or one more tap can be added for voltage regulation. The working control principle is similar to that of the above-mentioned two-chamber microwave oven, which is omitted here Listed; when designing, consider single-tube, two-tube, three-tube workloads and adjust the most suitable operating voltage at each point to achieve.

[0057] In the same way, if the furnace body is designed with n furnace chambers, JnA and JnB can be added to the corresponding circuit; the voltage deviation of...

Embodiment 3

[0058] Example Three: Please refer to Figure 7 As shown, the present invention provides a microwave oven using a frequency conversion switching modulation high voltage circuit and has two oven chambers, each heating element control terminal is connected to the control terminal of the frequency conversion switching modulation high voltage circuit through a relay, all relays All are controlled by the frequency conversion switching modulation high voltage circuit. The high-voltage circuit and the control circuit work together through relevant control signal communication. The filament on-off control relays J1B and J2B can be used, or they can be powered separately to control the magnetrons Q1 and Q2 to work in a single-tube or two-tube mode. Since the high-voltage output can be modulated to a suitable voltage operating point by the control circuit according to the load, the above-mentioned relay control circuit for the voltage input of the transformer is not needed. As the swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com