Evaluation method of stability of lithium-ion battery positive and negative electrode paste

A technology of lithium ion battery and evaluation method, which is applied in the field of evaluation of the stability of positive and negative electrode slurry of lithium ion battery, can solve the problems of slurry layering, battery performance impact, poor consistency of battery cells, etc., and achieves good reproducibility , Good practicability, accurate test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

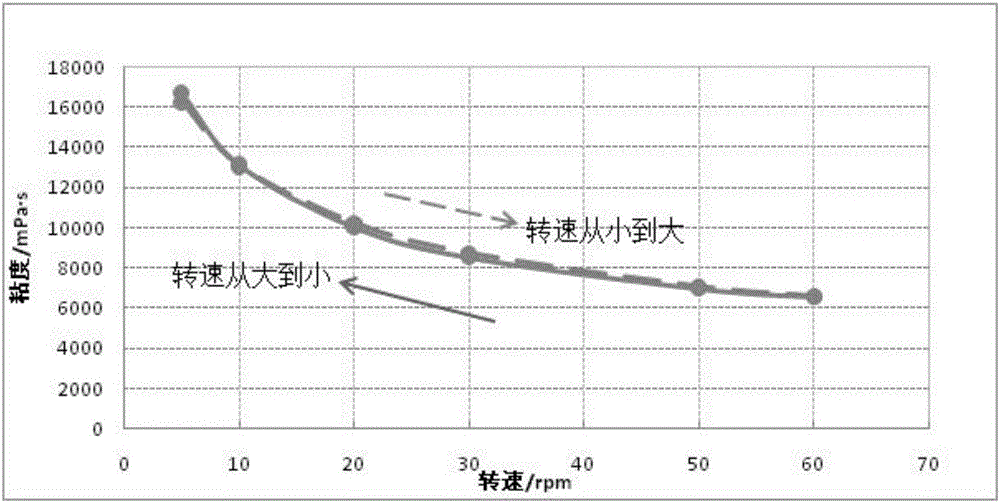

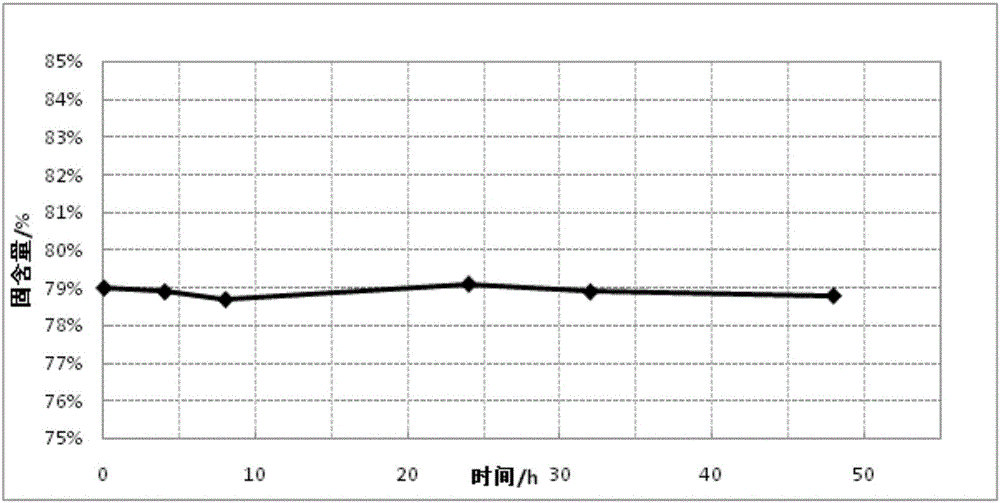

[0028] Weigh the positive active material lithium cobalt oxide (96% mass ratio, the same below), super conductive carbon black, and binder polyvinylidene fluoride, and use N-methylpyrrolidone as a solvent to prepare lithium cobalt oxide slurry according to the process design. . Take 250mL of fresh lithium cobalt oxide slurry and use the 5# rotor of the viscosity tester to test the viscosity of the slurry, set the rotation speed of the rotor to 5rpm, 10rpm, 20rpm, 30rpm, 50rpm, 60rpm in turn, record the viscosity value at each rotation speed, then Continue to set the rotational speed of the rotor to 60rpm, 50rpm, 30rpm, 20rpm, 10rpm, 5rpm, record the viscosity value at each rotational speed, and draw two viscosities according to the change of the viscosity value when the rotational speed changes from small to large and from large to small. The curve with the speed of rotation, the results are as follows figure 1 , figure 1 The middle dotted line is the change curve of viscosi...

Embodiment 2

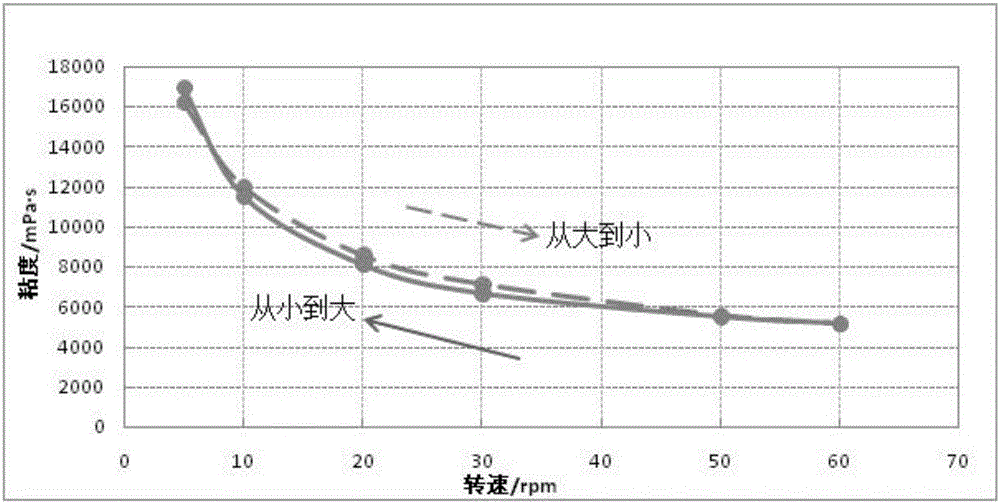

[0031] Weigh the positive active material ternary material (96% mass ratio, the same below), super conductive carbon black, binder polyvinylidene fluoride, and use N-methylpyrrolidone as a solvent to prepare a ternary slurry according to the process design. Take 500mL of fresh slurry and use the 5# rotor of the viscosity tester to test the viscosity of the slurry, set the rotation speed of the rotor to 5rpm, 10rpm, 20rpm, 30rpm, 50rpm, 60rpm in turn, record the viscosity value at each rotation speed, and then continue to rotate the rotor. The rotational speed is set to 60rpm, 50rpm, 30rpm, 20rpm, 10rpm, 5rpm, record the viscosity value at each rotational speed, and draw two changes of viscosity with rotational speed according to the change of the viscosity value when the rotational speed changes from small to large and from large to small. curve, the result is as image 3 , image 3 The middle dotted line is the change curve of viscosity with rotational speed when the rotatio...

Embodiment 3

[0034] Weigh the negative electrode active material graphite (96% mass ratio, the same below), super conductive carbon black, sodium carboxymethyl cellulose and styrene-butadiene rubber, use deionized water as a solvent, and prepare graphite slurry according to the process design. Take 1000 mL of fresh graphite slurry and use the 5# rotor of the viscosity tester to test the viscosity of the slurry, set the rotation speed of the rotor to 5rpm, 10rpm, 20rpm, 30rpm, 50rpm, 60rpm in turn, record the viscosity value at each rotation speed, and then continue Set the rotational speed of the rotor to 60rpm, 50rpm, 30rpm, 20rpm, 10rpm, and 5rpm, record the viscosity value at each rotational speed, and draw two viscosity curves according to the change of the viscosity value when the rotational speed changes from small to large and from large to small. The change curve of the speed, the results are as follows Figure 5 , Figure 5 The middle dotted line is the change curve of viscosity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com