An anti-condensation reactor for dynamic in-situ spectroscopic testing

An in-situ spectroscopy and reactor technology, applied in the field of reactors, can solve the problems of weak acquisition signal intensity, beam focusing interference, etc., to prevent condensation, improve temporal and spatial resolution, and improve the effect of condensation on high-transmittance optical windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

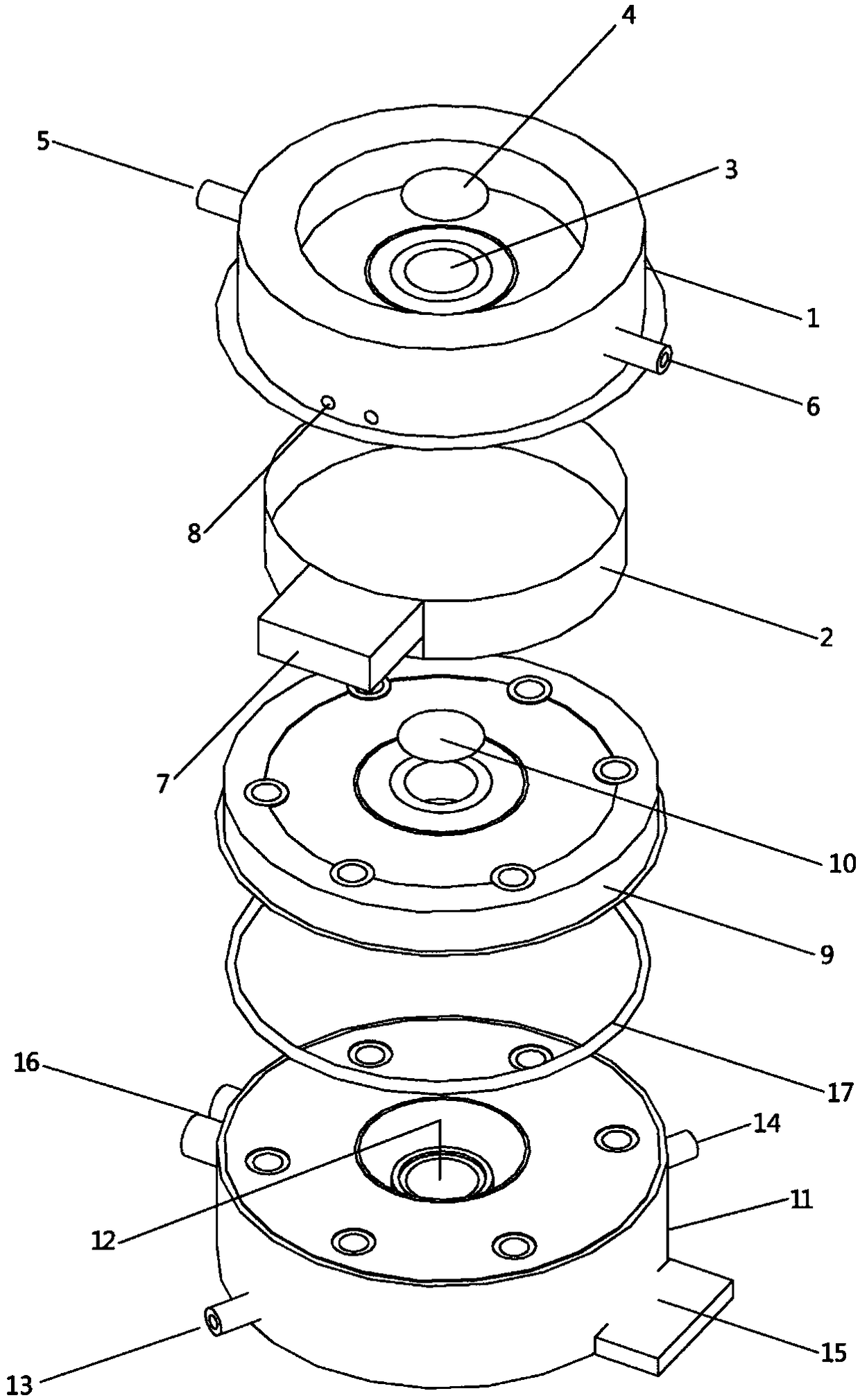

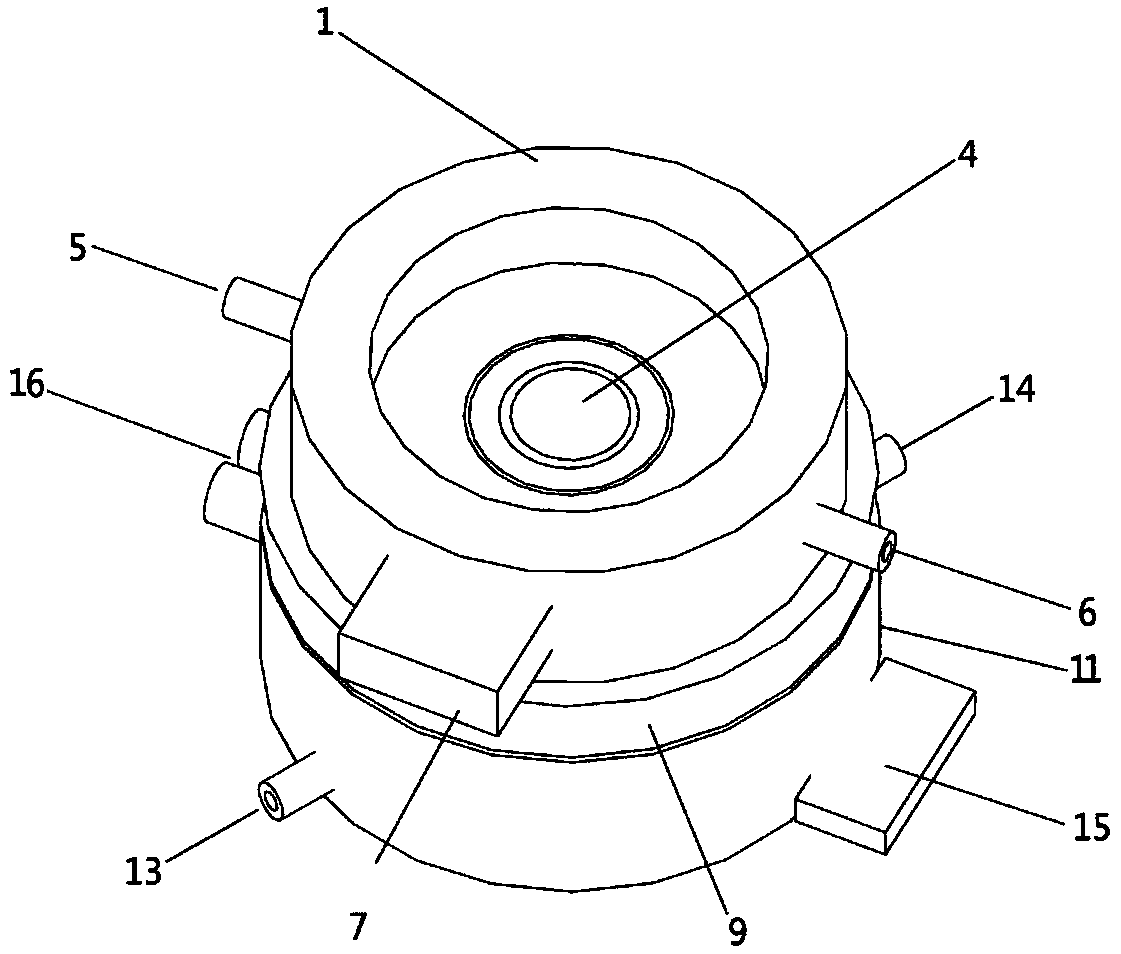

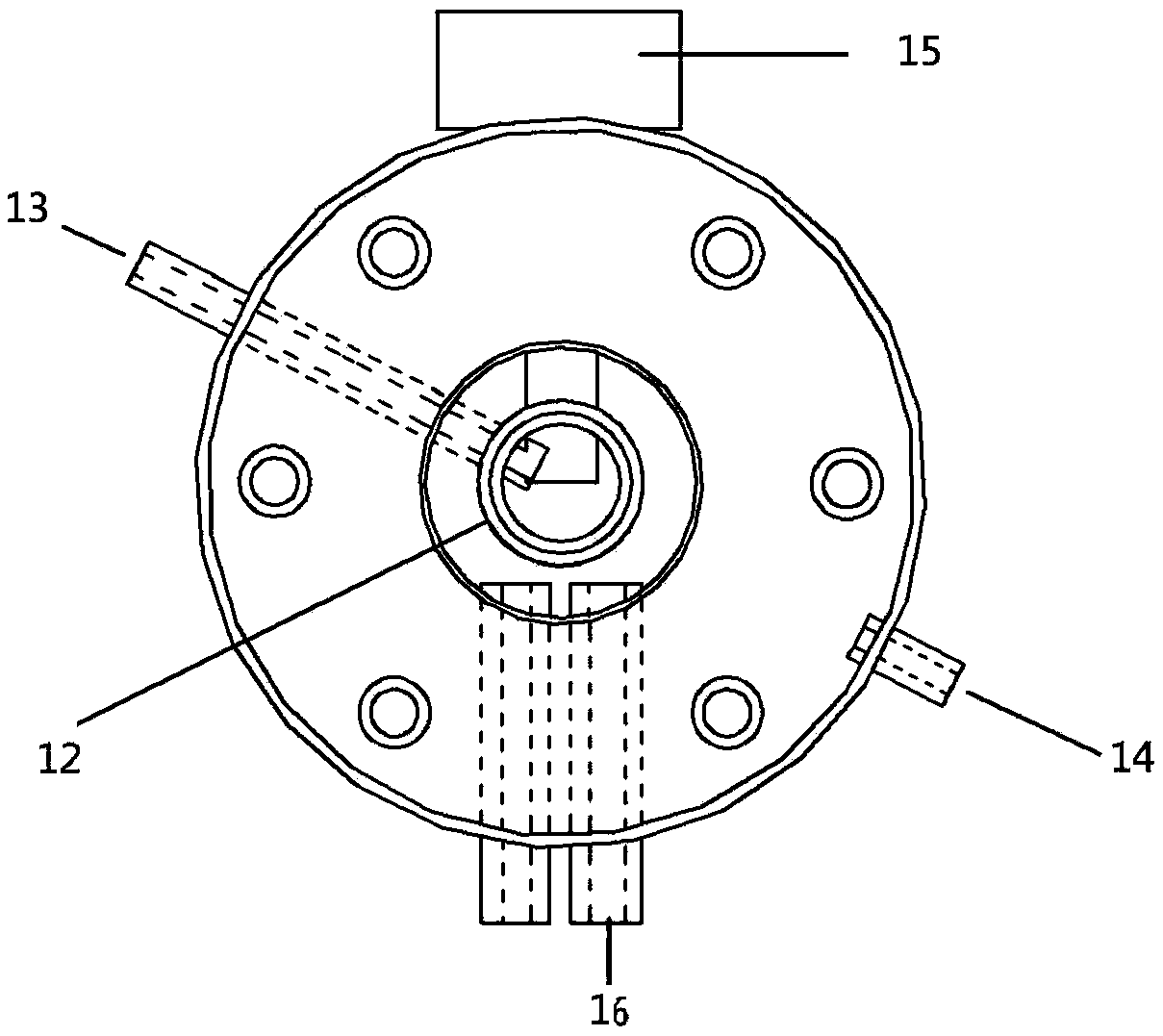

[0036] In this example, using figure 1 Shown is a dynamic in situ spectroscopic test using an anti-condensation reactor. The reactor main body 11 and the reactor cover 9 are made of stainless steel. The reactor main body 11 has a diameter of 62 mm and a height of 20 mm. The internal sample pool 12 has a diameter of 24 mm and a depth of 16 mm. 5mm. O-ring 17 has an outer diameter of 43.5mm and an inner diameter of 38.5mm. Both the high-transmittance optical window 4 in the low-pressure area and the high-transmission optical window 10 in the reactor have a diameter of 17 mm and a thickness of 1 mm. The outer diameter of the cover 1 in the low-pressure area is 54 mm and the wall thickness is 3 mm. A light hole 3 with a diameter of 16mm is provided at the center of the low-pressure area cover 1, and the diameter of the annular heating belt 2 is 30mm.

[0037]Under the indoor condition of humidity 90%, temperature 35 ℃, carry out the Raman (Raman) field dynamic in-situ experimen...

Embodiment 2

[0039] The anti-condensation type reactor adopted in this embodiment is the same as that in Embodiment 1. Under the conditions of 260°C and 2MPa, Fe-based Fischer-Tropsch synthesis was used to prepare high value-added chemicals. The catalyst samples were first filled in the sample cell 12 with quartz wool pads. After the samples were compacted and leveled, the reactor cover 9 and The O-ring 17 seals the reactor main body 11 and the reactor cover 9 with bolts and nuts. Then cover the low-pressure zone cover 1, feed the non-condensable inert gas high-purity argon into the gas delivery inlet 5 of the low-pressure zone, then vacuumize the low-pressure zone to a vacuum degree of 0.08MPa, and heat the low-pressure zone to 200°C. The cooling water channel 16 is connected to an external circulating low-temperature tank, and water is used as cooling liquid to assist in temperature control. Fix the installed reactor on the detection platform, adjust the position of the lens and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com