Method for carrying out chromatographic test pretreatment on lithium battery electrolyte

An electrolyte and lithium battery technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as interference and large loss of chromatographic column, and achieve the effects of fast speed, simple pretreatment process and less time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

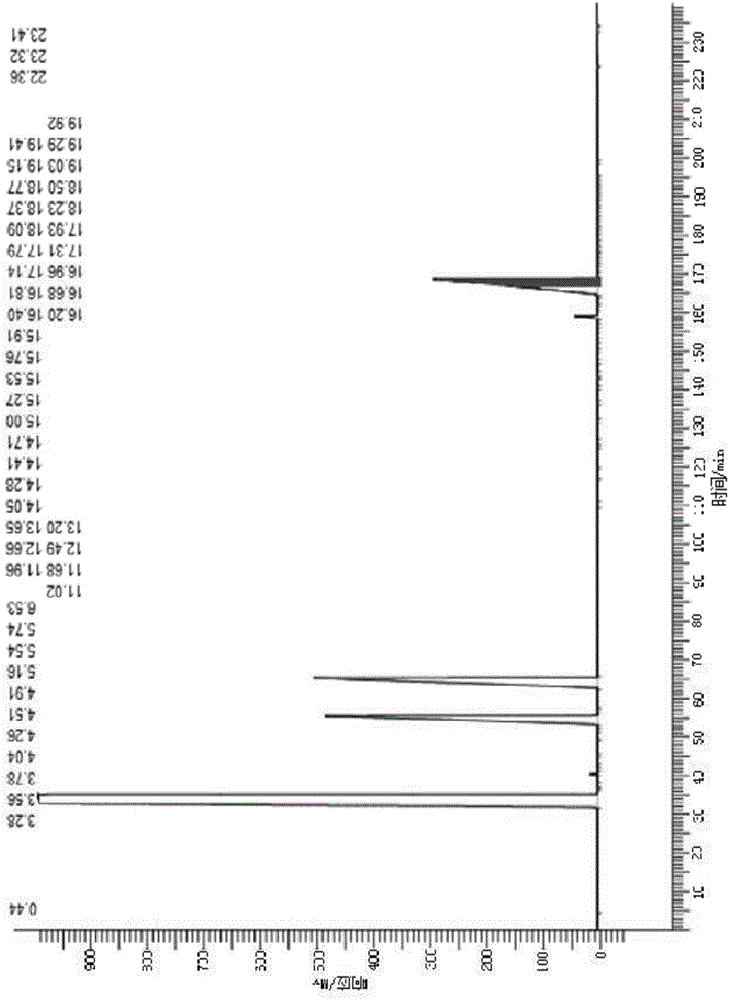

Embodiment 1

[0024] A method for pretreatment of lithium battery electrolyte chromatography test, the steps are as follows:

[0025] (1) Prepare a sodium carbonate solution with a purity of 99.9% into a saturated aqueous sodium carbonate solution;

[0026] (2) Take the saturated sodium carbonate aqueous solution in a centrifuge tube, then add the electrolyte sample and vortex for 5 minutes, wherein the volume ratio of the saturated sodium carbonate aqueous solution to the electrolyte sample is 2:1;

[0027] (3) Add the organic solvent ethyl acetate according to the volume ratio of the organic solvent and the electrolyte at 1:2, continue to vortex for 10 minutes, then let it stand for at least 10 minutes, and after it is completely separated, take out the upper liquid and put it in a glass sample bottle;

[0028] (4) Repeat the above step (3) twice;

[0029] (5) Blow the glass sample bottle with nitrogen at a low temperature of 15°C, remove the organic solvent ethyl acetate, and make the l...

Embodiment 2

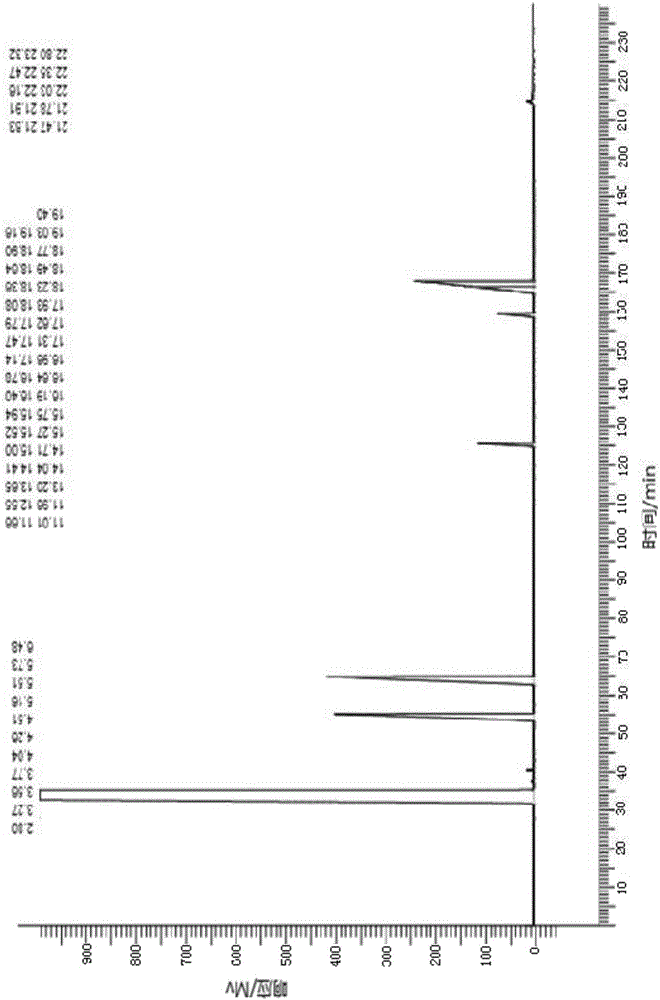

[0031] A method for pretreatment of lithium battery electrolyte chromatography test, the steps are as follows:

[0032] (1) Prepare a sodium carbonate solution with a purity of 99.9% into a saturated aqueous sodium carbonate solution;

[0033] (2) Take the saturated sodium carbonate aqueous solution in a centrifuge tube, then add the electrolyte sample and vortex for 3 minutes, wherein the volume ratio of the saturated sodium carbonate aqueous solution to the electrolyte sample is 3:1;

[0034] (3) According to the volume ratio of organic solvent and electrolyte of 1:5, add the organic solvent n-hexane and continue to vortex for 20 minutes, and then let it stand for at least 5 minutes. After it is completely separated, take out the upper liquid and put it in a glass sample bottle;

[0035] (4) Repeat the above step (3) twice;

[0036] (5) Blow the glass sample bottle with nitrogen at a low temperature of 10°C to remove the organic solvent and make the liquid in the glass samp...

Embodiment 3

[0038] A method for pretreatment of lithium battery electrolyte chromatography test, the steps are as follows:

[0039] (1) Prepare a sodium carbonate solution with a purity of 99.9% into a saturated aqueous sodium carbonate solution;

[0040] (2) Take the saturated sodium carbonate aqueous solution in a centrifuge tube, then add the electrolyte sample and vortex for 10 minutes, wherein the volume ratio of the saturated sodium carbonate aqueous solution to the electrolyte sample is 20:1;

[0041] (3) Add the organic solvent toluene according to the volume ratio of the organic solvent and the electrolyte at 1:10, continue to vortex for 5 minutes, and then let it stand for at least 15 minutes. After the layers are completely separated, take out the upper liquid and place it in a glass sample bottle;

[0042] (4) Repeat the above step (3) twice;

[0043] (5) Blow the glass sample bottle with nitrogen at a low temperature of 25°C to remove the organic solvent and make the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com