High-sensitivity micro-nano giant piezoresistive rain sensor and its preparation method and measurement structure

A rain sensor and high-sensitivity technology, applied in the field of micro-nano electro-mechanical system sensor design, can solve the problems of small strain coefficient of silicon piezoresistors, difficulty in measurement, and restrictions on wide application of manufacturing processes, so as to improve accuracy and detection sensitivity , the effect of improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

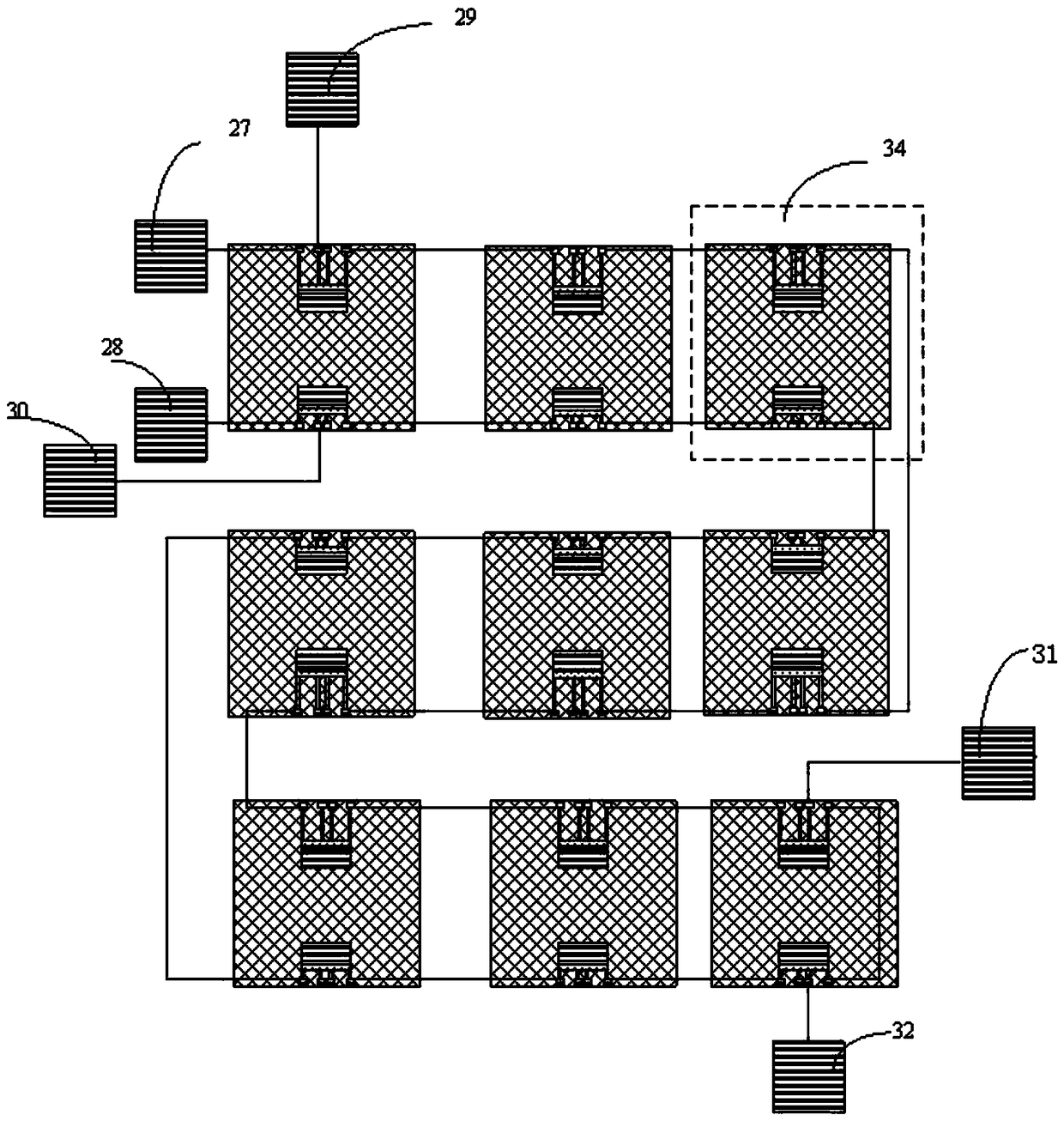

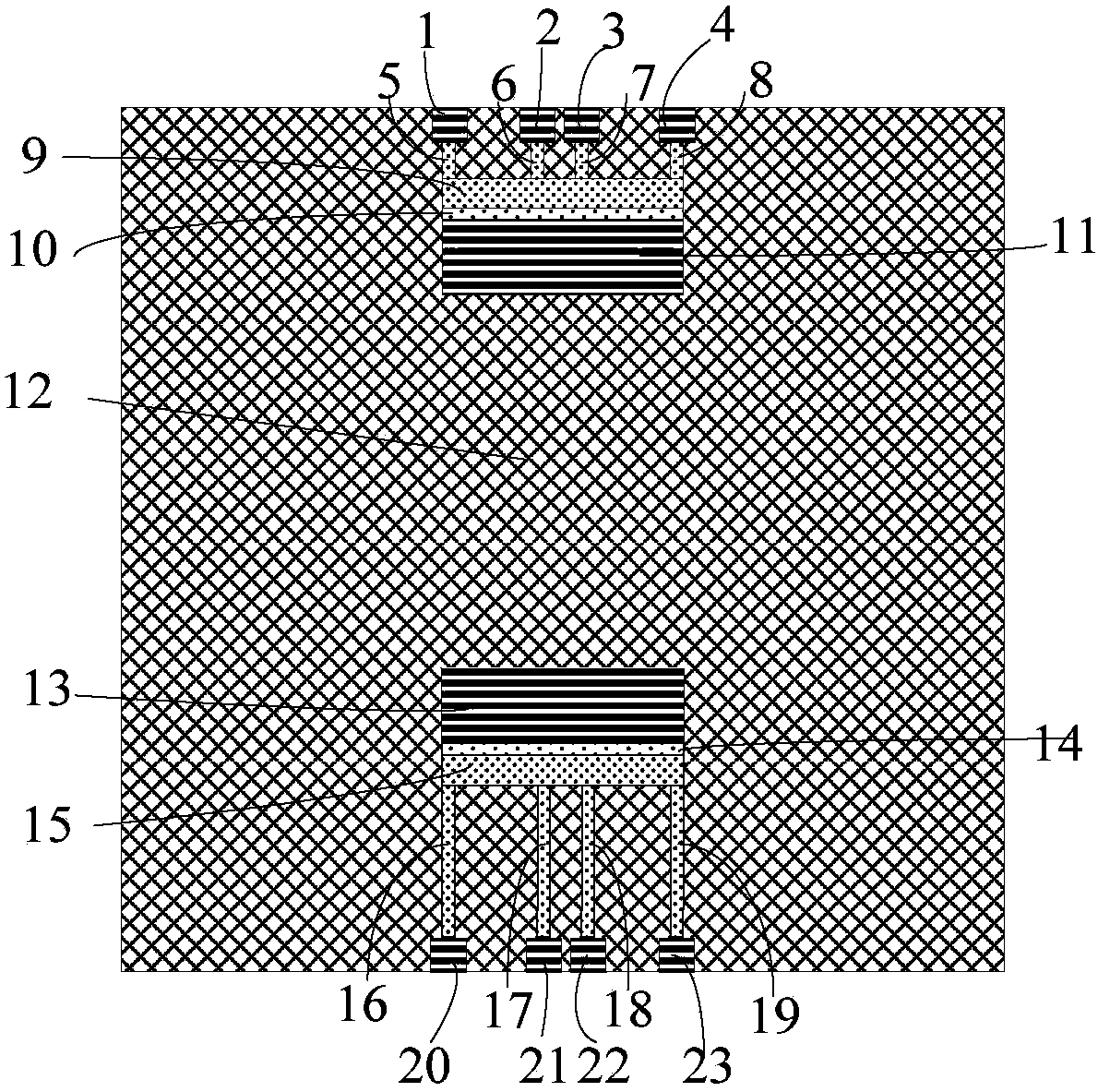

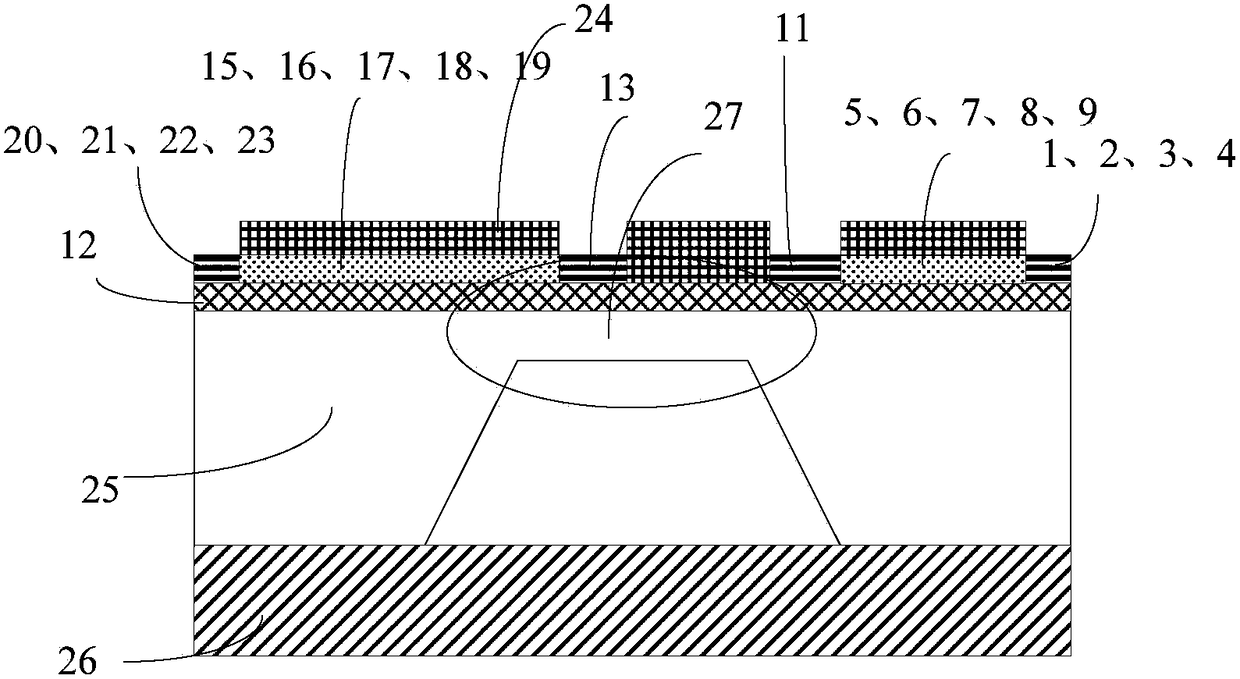

[0058] refer to figure 1 , in this embodiment, the sensor array includes 9 sensing units in a structure of 3 rows×3 columns. Compared with a single sensor unit, the advantage of the sensor array is that it can reflect the overall change of the pressure in a region, but if it is set to a larger number of sensor units, it will increase the difficulty of wiring, and the number of sensors connected in series is too large It will cause the resistance of the sensor to be too large and it is not convenient to measure, but the 3×3 design structure can ensure the high sensitivity of the sensor and measure the pressure change within a certain range, which is suitable for the measurement of the rainfall change signal.

[0059] refer to Figure 4 , the present invention also includes a bracket 35, the bracket 35 is a hemisphere, and a plurality of sensor array installation slots 36 are evenly distributed on it, and the sensor array is installed in the installation slots. In application,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com