Composite resistor for head cover of power battery

A technology of composite resistors and power batteries, which is applied in the direction of battery covers/end covers, resistors, battery pack components, etc., can solve the problems of low test safety performance and high production costs, and achieve improved volume and mass energy density, good safety High performance and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

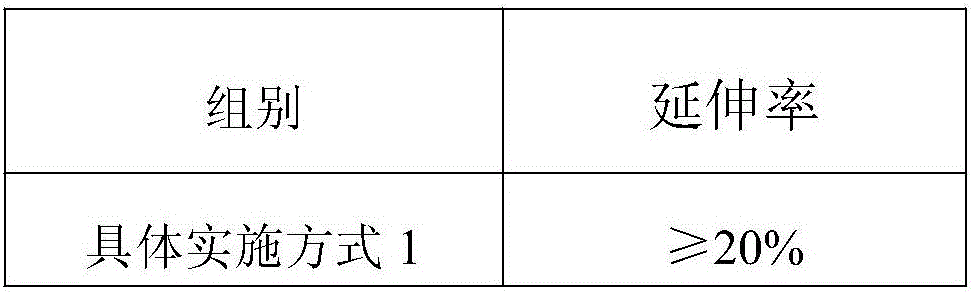

specific Embodiment approach 1

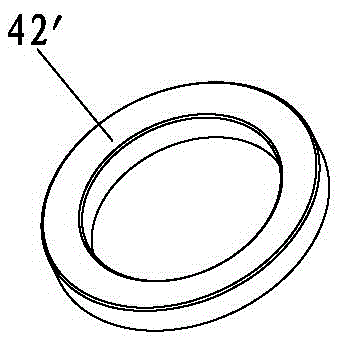

[0025] Such as figure 1 As shown, the shape of the composite resistor 42 of the present invention is set as a circular ring, which includes a conductive component A and an insulating plastic component B, wherein the conductive component A is graphite, and its content is 40wt%; the insulating plastic component B is Polyether ether ketone, its content is 60wt%.

[0026] The manufacturing method of the composite resistor 42 is as follows: step 1, uniformly mix the conductive component A and the insulating plastic component B, and press and form it in the mold; step 2, perform ventilation treatment on the pressed composite resistor at a temperature of 30°C, The processing time is 6 hours; Step 3, then enter the drying oven for drying, the drying temperature is 80° C., and the drying time is 10 hours; that is, a composite resistor 42 with a resistance value of 200Ω, a heat-resistant temperature of 350° C., and a thickness of 0.1 mm is obtained.

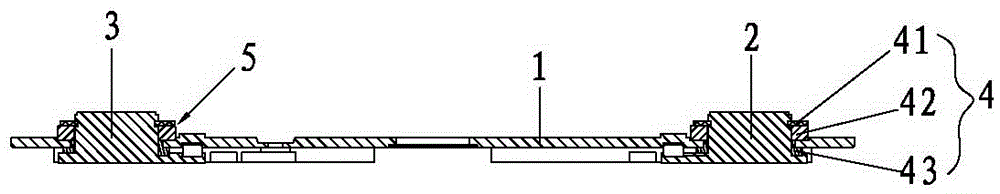

[0027] Such as figure 2 As shown...

specific Embodiment approach 2

[0028]Different from Embodiment 1, the conductive component A is conductive carbon black with a content of 50wt%; the insulating plastic component B is polyimide with a content of 50wt%; the resulting resistance is 300Ω, heat-resistant A composite resistor 42 with a temperature of 350°C and a thickness of 10mm.

[0029] Others are the same as those in Embodiment 1, and will not be repeated here.

specific Embodiment approach 3

[0030] Different from Embodiment 1, the conductive component A is graphene with a content of 45wt%; the insulating plastic component B is polybenzimidazole with a content of 55wt%; 1000°C and a composite resistor 42 with a thickness of 0.01mm.

[0031] Others are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com