Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of semiconductor device electrical characteristic degradation and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

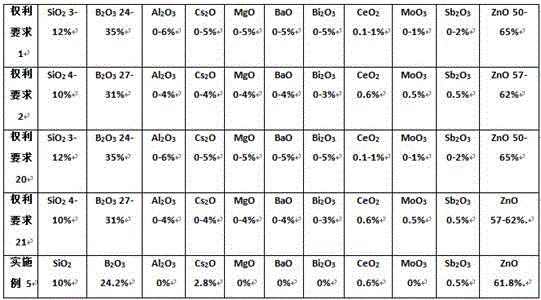

[0017] A semiconductor device using a glass passivation layer based on aluminosilicate, such as lead oxide (PbO) or (ZnO) zinc oxide aluminosilicate. In order to increase the reliability of the semiconductor device under reverse bias and high temperature thermal stress, the aluminosilicate glass passivation layer contains cesium at a concentration of 20ppm (mol, mole percent) to 200ppm (mol, mole percent).

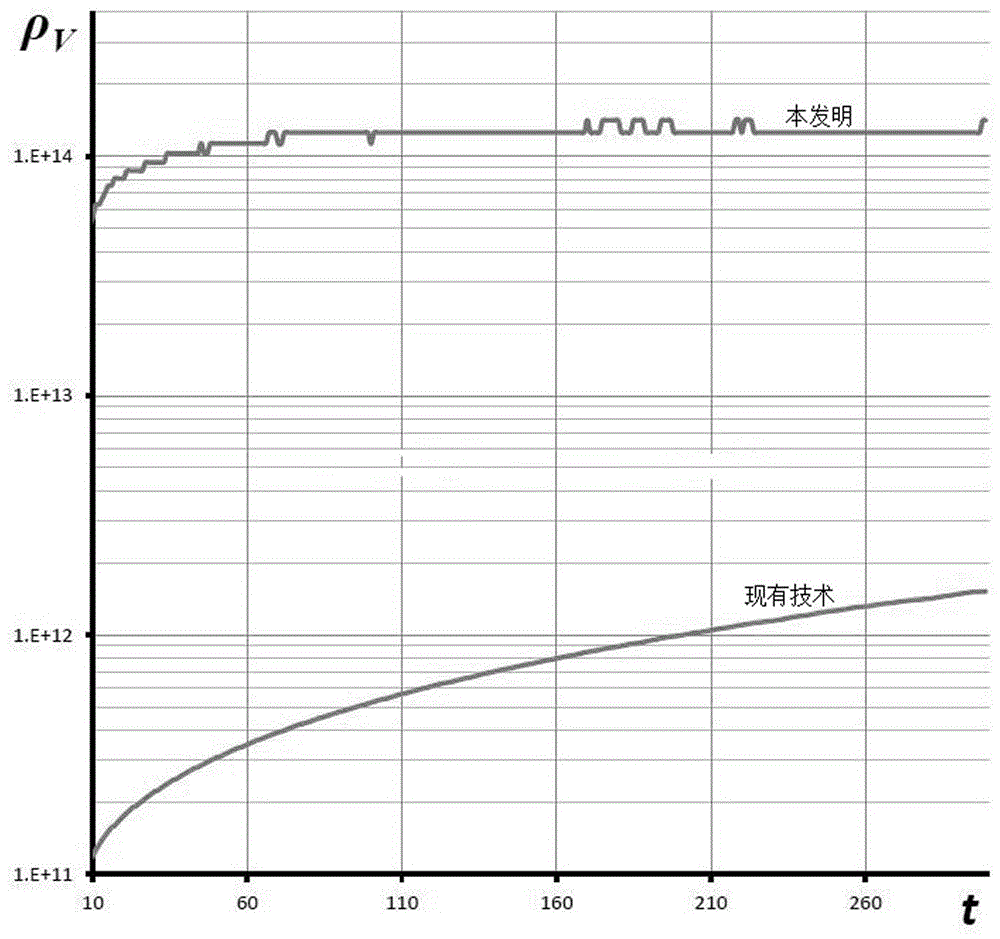

[0018] The results of XPS (X-ray photoelectron spectroscopy, X-ray photoelectron spectroscopy) technology measurement show that the concentration of cesium on the surface of the glass passivation layer is consistent with the setting of the present invention, specifically 5*10 18 cm -3 . We compare the resistivity of the glass passivation layer (measured using ASTM D-257) to 2*10 11 Ω·cm - 3*10 11 The range of Ω·cm has been increased to 1.5*10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com