l10-mnga or l10-mnal base wide linear response magnetic sensor and preparation method

A l10-mnal, magnetic sensor technology, applied in the fields of magnetic field-controlled resistors, electromagnetic device manufacturing/processing, material selection, etc., can solve the problem that the permanent magnet thin film increases the process difficulty and manufacturing cost, and it is difficult to miniaturize the device. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

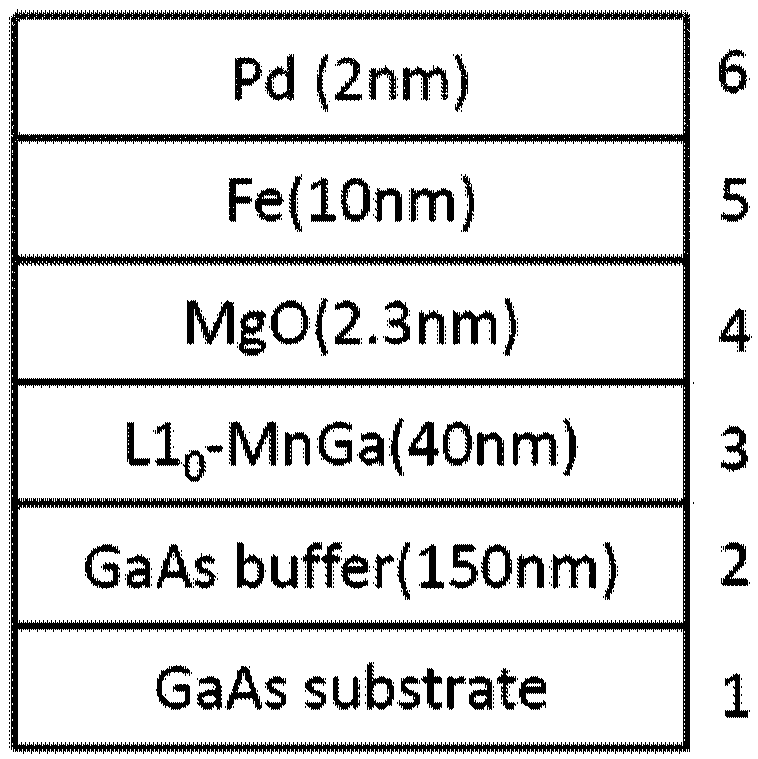

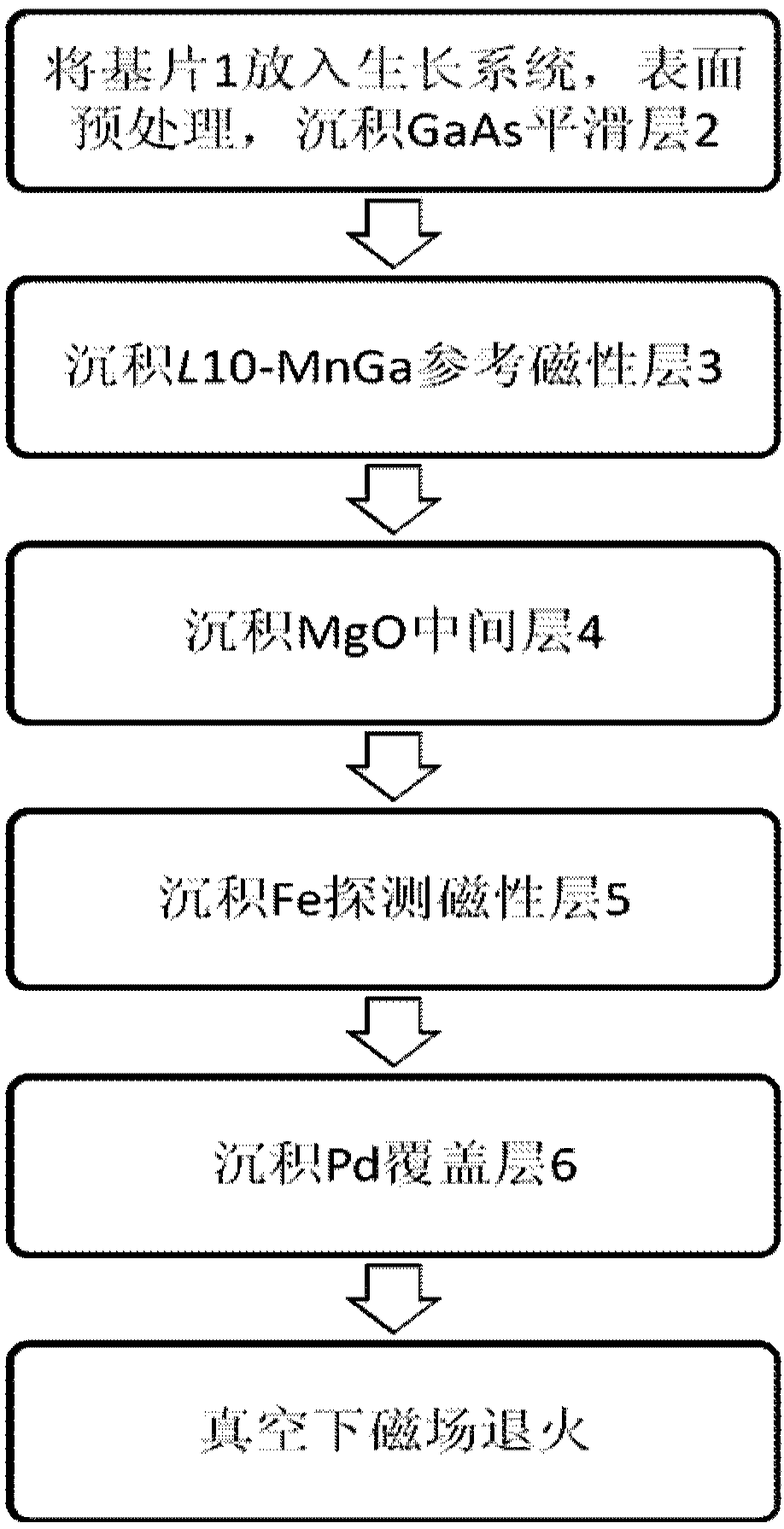

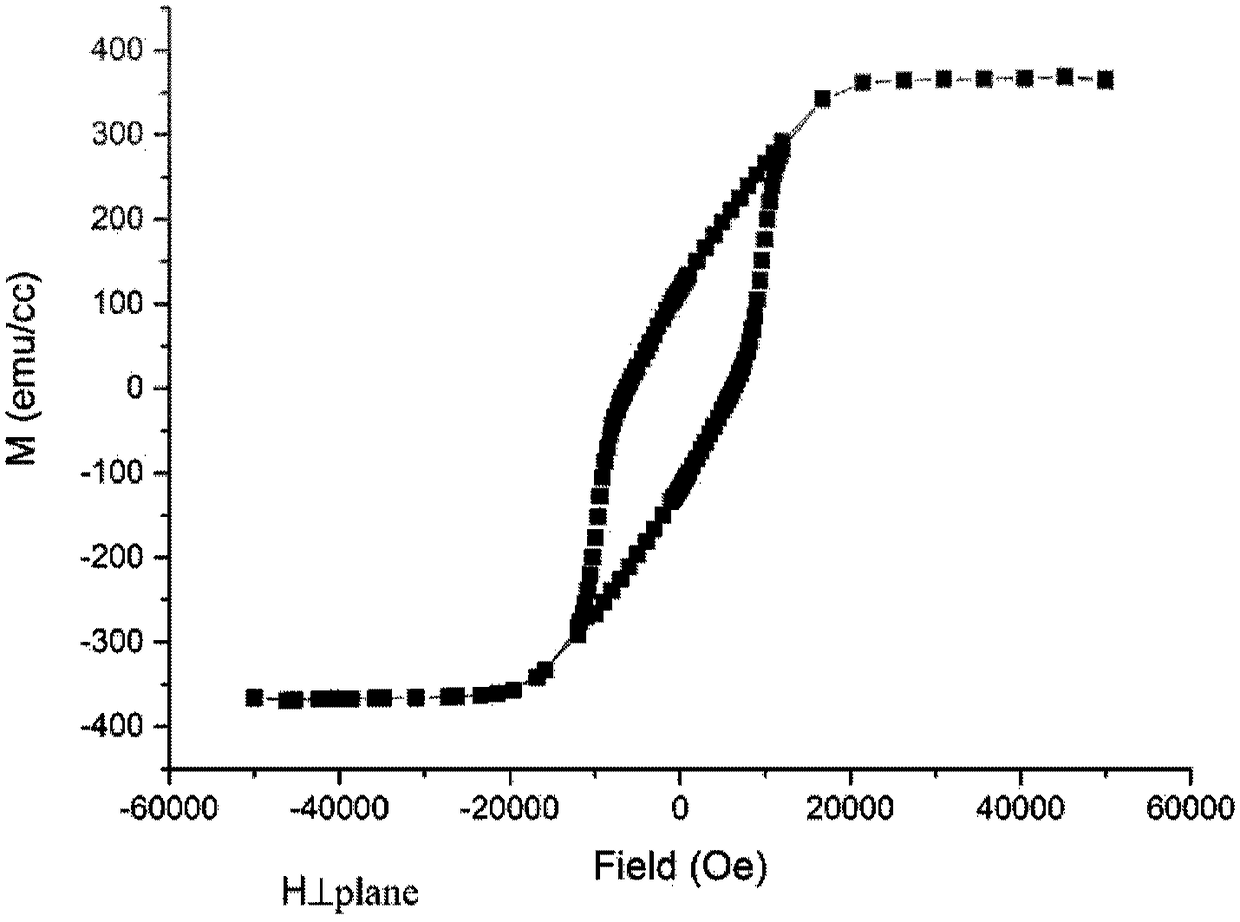

[0027] In order to more clearly illustrate the principle and implementation characteristics of the present invention, it will be combined with L1 0 - MnGa-based multilayer film wide linear response magnetic sensor example to further illustrate the present invention. see figure 1 As shown, the present invention provides a L1 0 -MnGa or L1 0 -MnAl-based wide linear response magnetic sensor, its sample structure includes: a substrate 1, the material of the substrate 1 is a CaAs (001) substrate; a smooth layer 2, which is made on the substrate 1, the smooth The material of layer 2 is GaAsbuffer, the thickness is 150nm; a reference magnetic layer 3, which is made on the smooth layer 2, L1 0 -MnGa(MnAl) or L1 0 -MnGa / FM or L1 0 -MnAl / FM bilayer film with a thickness of 40nm. Under zero field, the magnetization direction of the reference magnetic layer 3 is perpendicular to the film surface of the sensor multilayer film, and is perpendicular to the magnetic moment of the subse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com