Disassembling method and apparatus for lithium battery shell

A lithium battery and shell technology, which is applied in the field of lithium battery recycling and recycling, can solve problems such as low shell disassembly efficiency, and achieve the effects of convenient separation, convenient large-scale and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for dismantling a lithium battery casing, comprising the following steps:

[0031] (1) Disassemble the battery pack or battery module into single lithium batteries after discharge;

[0032] (2) Place the lithium battery on the laser cutting platform, and make the cover end of the lithium battery protrude from the outside of the laser cutting platform and its length outside the laser cutting platform is 1 / 5 of the total height of the battery; then use laser cutting The device cuts the connection between the cover plate and the shell of the lithium battery, and the position of the ring cut is 0.2cm away from the cover plate, so that the shell and the cover plate are separated;

[0033] (3) Pull the cover away from the case, so that the cell and tabs are exposed from the case, and the length of the cell exposed to the case is 1 / 5 of the height of the entire cell; then use a laser cutter to cut off the tabs, so that The cover plate is separated from the battery co...

Embodiment 2

[0035] A method for dismantling a lithium battery casing, comprising the following steps:

[0036] (1) Disassemble the battery pack or battery module into single lithium batteries after discharge;

[0037] (2) Place the lithium battery on the laser cutting platform, and make the cover end of the lithium battery protrude from the outside of the laser cutting platform and its length outside the laser cutting platform is 1 / 2 of the total height of the battery; then use laser cutting The device cuts the connection between the cover plate and the shell of the lithium battery, and the position of the ring cut is 1.5cm away from the cover plate, so that the shell and the cover plate are separated;

[0038] (3) Pull the cover away from the case, so that the cell and tabs are exposed from the case, and the length of the cell exposed to the case is 1 / 2 of the height of the entire cell; then use a laser cutter to cut off the tabs, so that The cover plate is separated from the battery co...

Embodiment 3

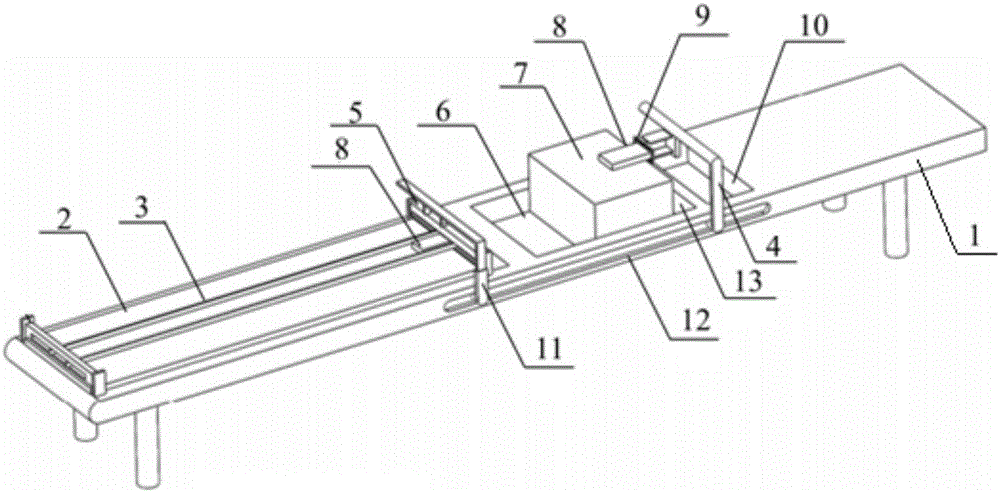

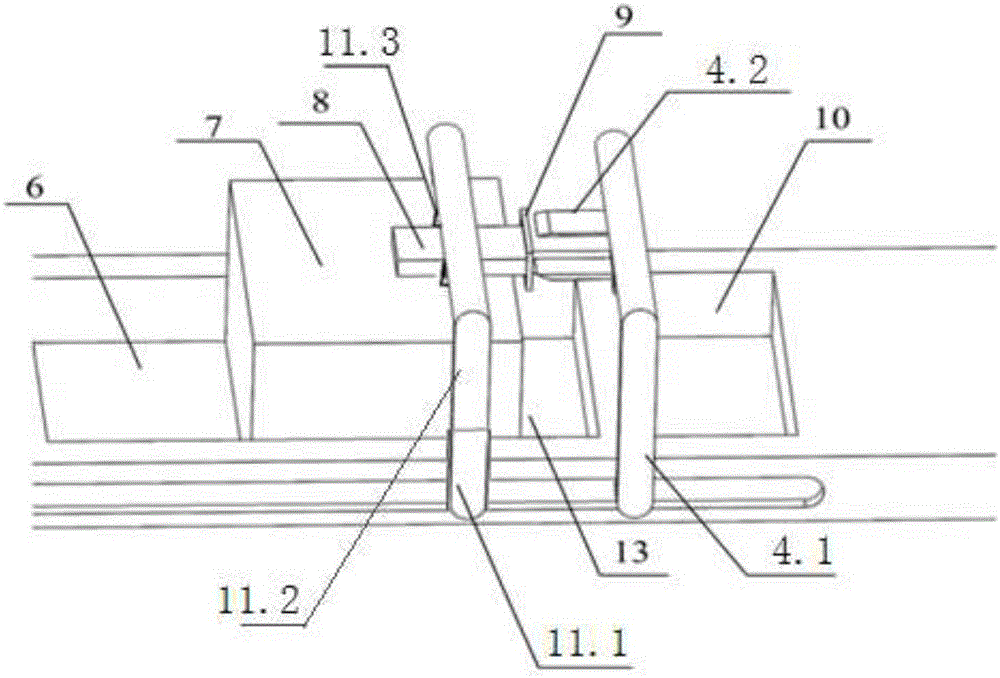

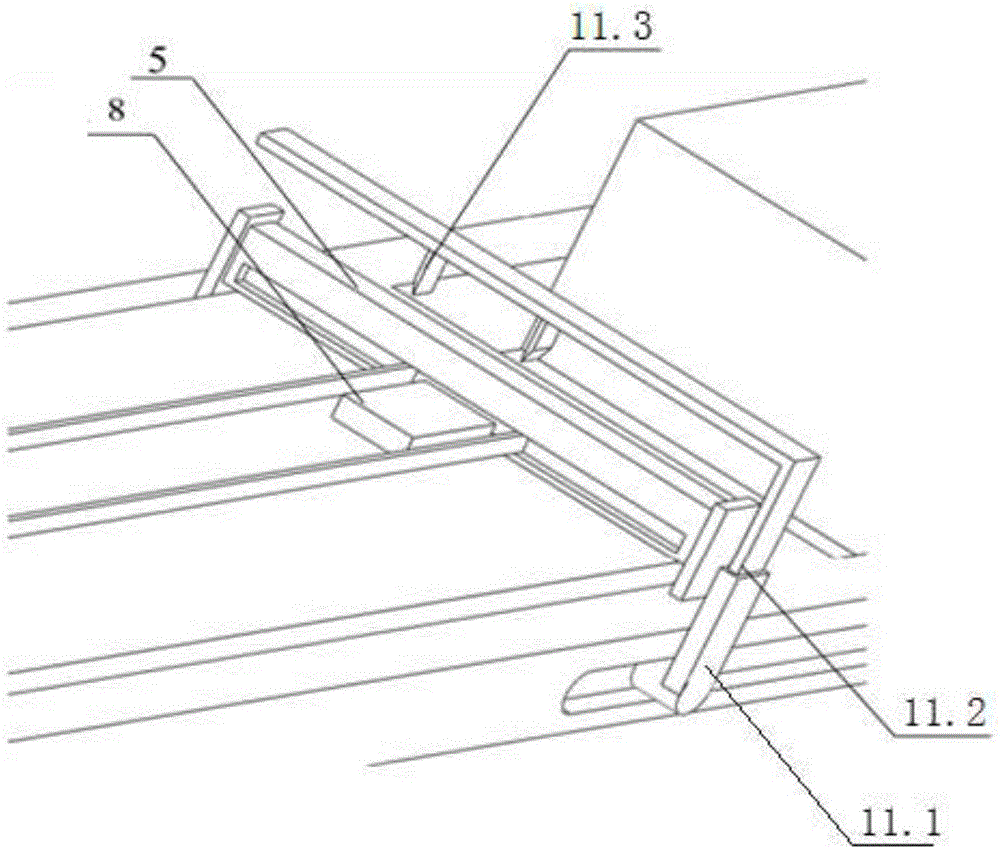

[0040] Such as figure 1 , 2 , 3, a device for dismantling a lithium battery shell, including a work frame 1, the two ends of the work frame 1 are respectively provided with a conveyor belt 2 and a laser cutting platform 7, and the laser cutting platform 7 is provided with Laser cutter; a stop baffle 5 is erected on the work frame 1 at the output end of the conveyor belt 2, and a guide groove 12 is fixed on one side of the work frame 1, and the first manipulator 11 and the first manipulator 11 are respectively slid on the guide groove 12 The second manipulator 4.

[0041] In a further solution, the bottom end of the stop baffle 5 is fixed with an inductor for sensing a lithium battery 8, and the output end of the inductor is connected to the motor of the conveyor belt 2 through a normally closed relay.

[0042] In a further solution, the middle of the conveyor belt 2 is provided with limit side baffles 3 in parallel along its running direction, and the distance L between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com