Compound sulfachloropyrazine sodium soluble powder and preparation method thereof

A sulfachloropyrazine sodium and soluble technology is applied in the compound sulfachloropyrazine sodium soluble powder and the field of preparation thereof, which can solve the problems of difficulty in achieving a therapeutic effect, uneven effect of compound drugs, etc. The effect of human food safety and drug cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

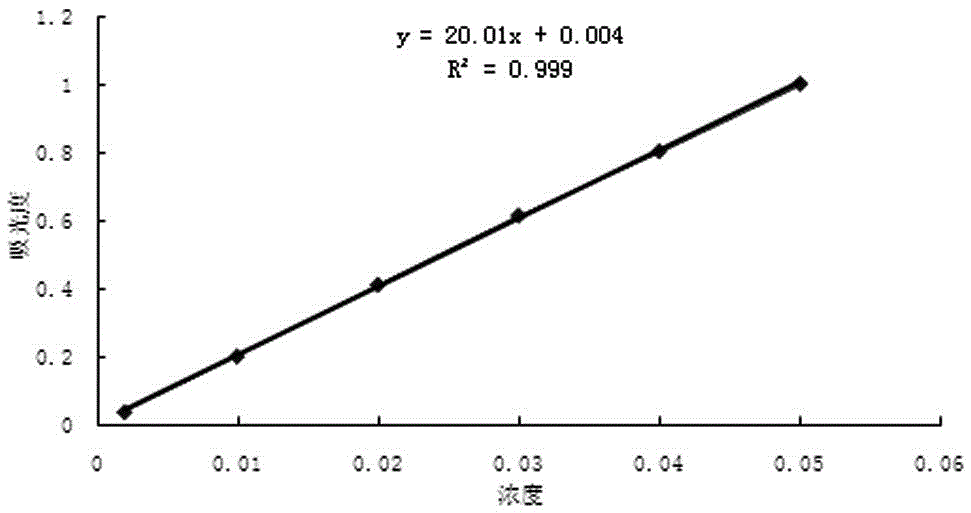

Image

Examples

Embodiment 1

[0029] A compound sulfachlorpyrazine sodium soluble powder, each 100g soluble powder is made of the following components: sulfachlorpyrazine sodium 20g, synergist (trimethoprim) 4g, carrier I (polyethylene glycol 6000) 50g , Carrier II (polyvinylpyrrolidone K30) 4g, maltodextrin 10g, anhydrous glucose 12g.

[0030] Its preparation method comprises the following steps:

[0031] (1) Heat and melt the carrier I at 75-85°C to a liquid state, add synergist while it is hot, stir for 20 minutes, and dissolve to obtain system A;

[0032] (2) Mix maltodextrin and carrier II evenly, add to system A and mix, maintain the temperature at 90-100°C, and stir for 30 minutes. The system is uniform milky white without large particles, and system B is obtained;

[0033] (3) Spread the system B evenly, and solidify it in ice water for 4 hours under the environmental condition that the relative humidity is not higher than 40%, to obtain white solid C;

[0034] (4) Pulverize the solid C at room t...

Embodiment 2

[0037] A kind of compound sulfachlorpyrazine sodium soluble powder, the component in every 100g soluble powder is with embodiment 1.

[0038] Its preparation method is, adopt following steps:

[0039] a) Mix the synergist, carrier Ⅰ, carrier Ⅱ and maltodextrin, and after the mixture is hot-melt extruded, cool, crush, and pass through a 100-mesh sieve; the temperature of hot-melt extrusion in step a) is 75-85°C ;The cooling temperature is 0~4℃;

[0040] b) Pulverize sulfachlorpyrazine sodium and anhydrous glucose, pass through a 100-mesh sieve, and mix the undersize with the undersize in step a) in a three-dimensional mixer for 30 minutes.

Embodiment 3

[0042] A compound sulfachlorpyrazine sodium soluble powder, the components in every 100g soluble powder are sulfachlorpyrazine sodium 15g, synergist (ditrimethoprim) 3g, carrier I (polyethylene glycol 6000) 40g, Carrier II (polyvinylpyrrolidone K30) 2g, maltodextrin 5g, anhydrous glucose 35g.

[0043] Its preparation method is the same as that of Example 1, the difference being that in step 1) it is stirred for 30 minutes, and in steps (4) and (5) it is passed through an 80-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com