A high-speed filter with a siphon automatic residual pressure exhaust diversion pressure relief device

A pressure relief device and filter technology, applied to loose filter material filters, gravity filters, filter separation, etc., can solve the problems of shortened service life of exhaust valves and high-speed filters, unstable filtered water flow, etc. Achieve the effects of eliminating exhaust noise pollution, convenient and safe cleaning, and improving performance ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

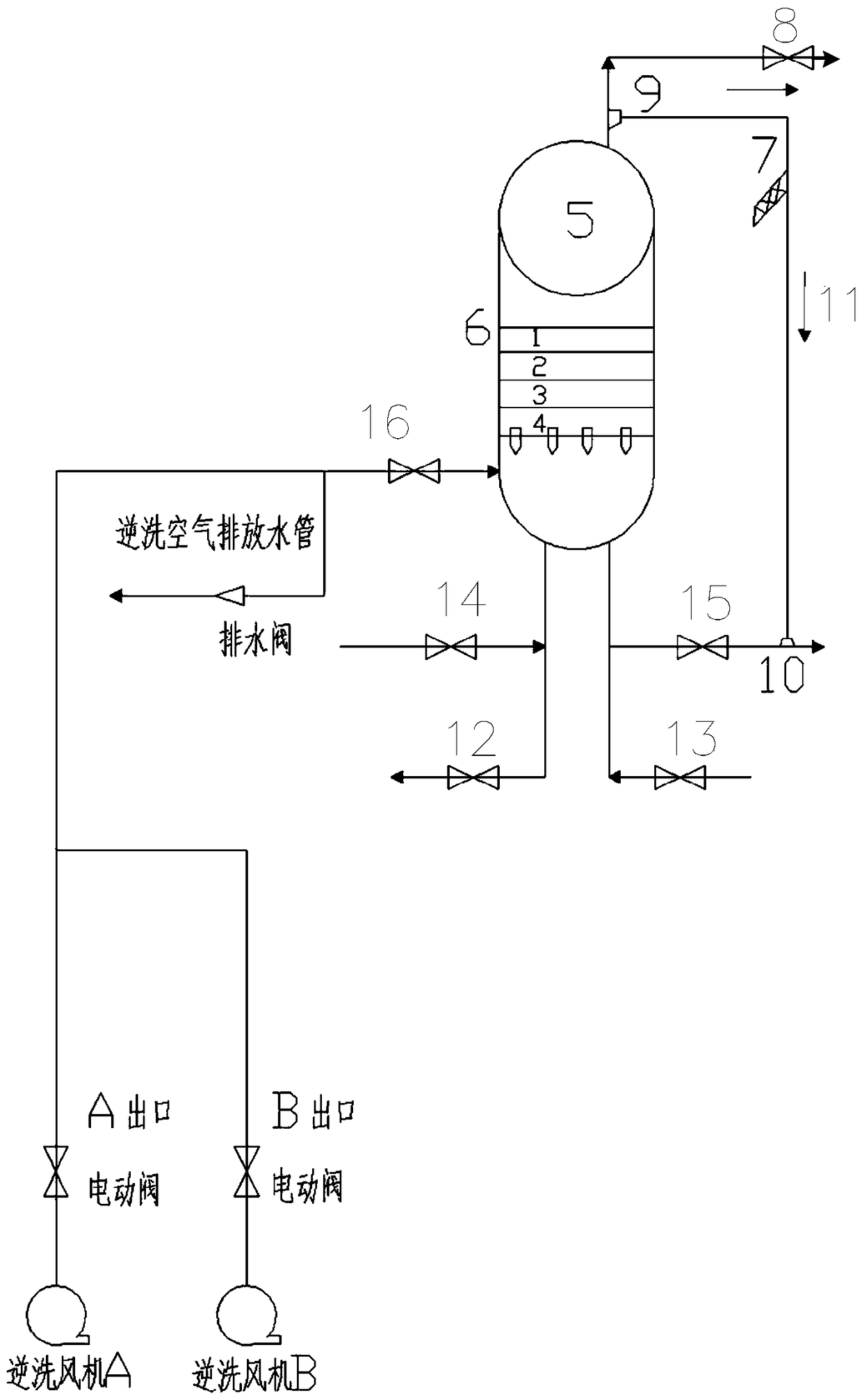

[0028] A specific embodiment of the high-speed filter with a siphon automatic residual pressure exhaust diversion pressure relief device of the present invention includes six high-speed filters in a certain circulating water work area, and its siphon automatic residual pressure exhaust diversion pressure relief device The main parameters of are as follows:

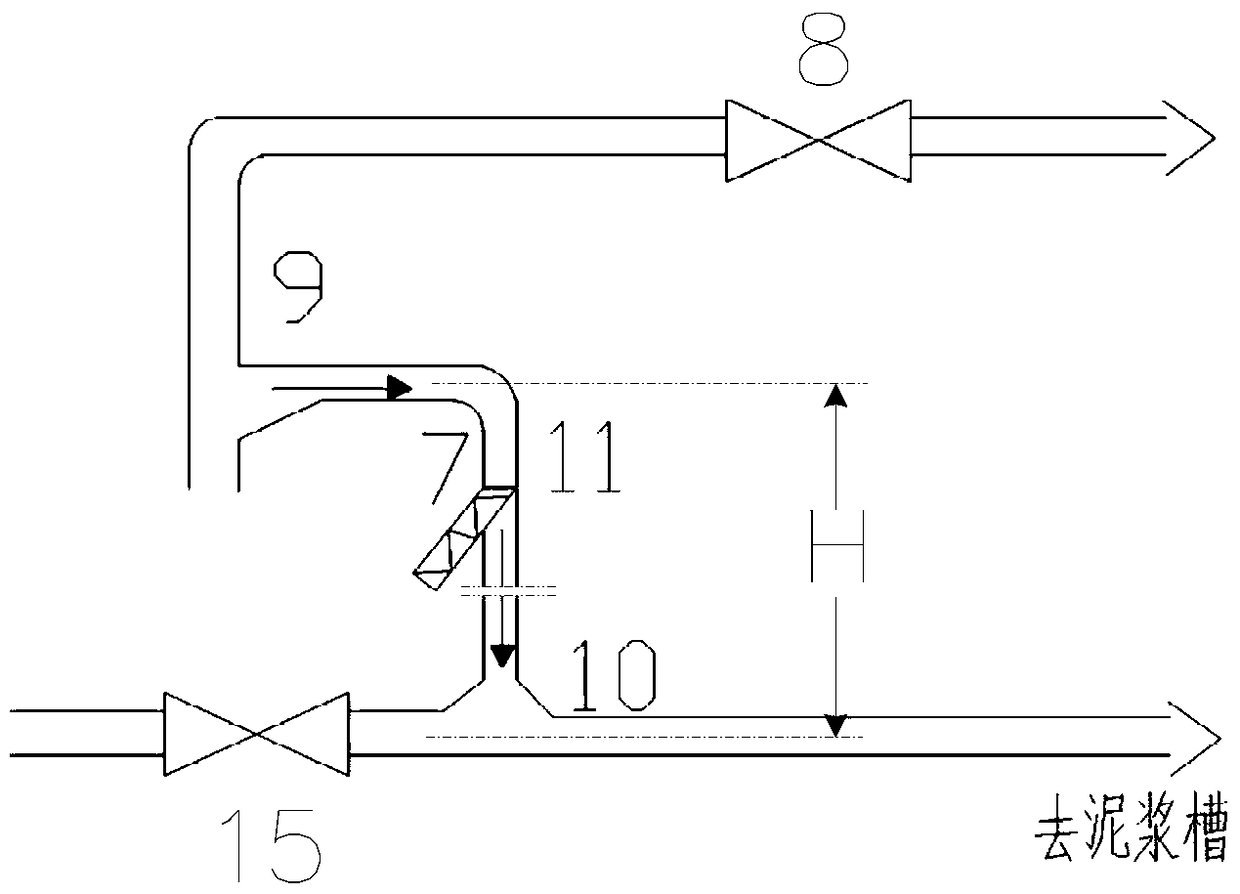

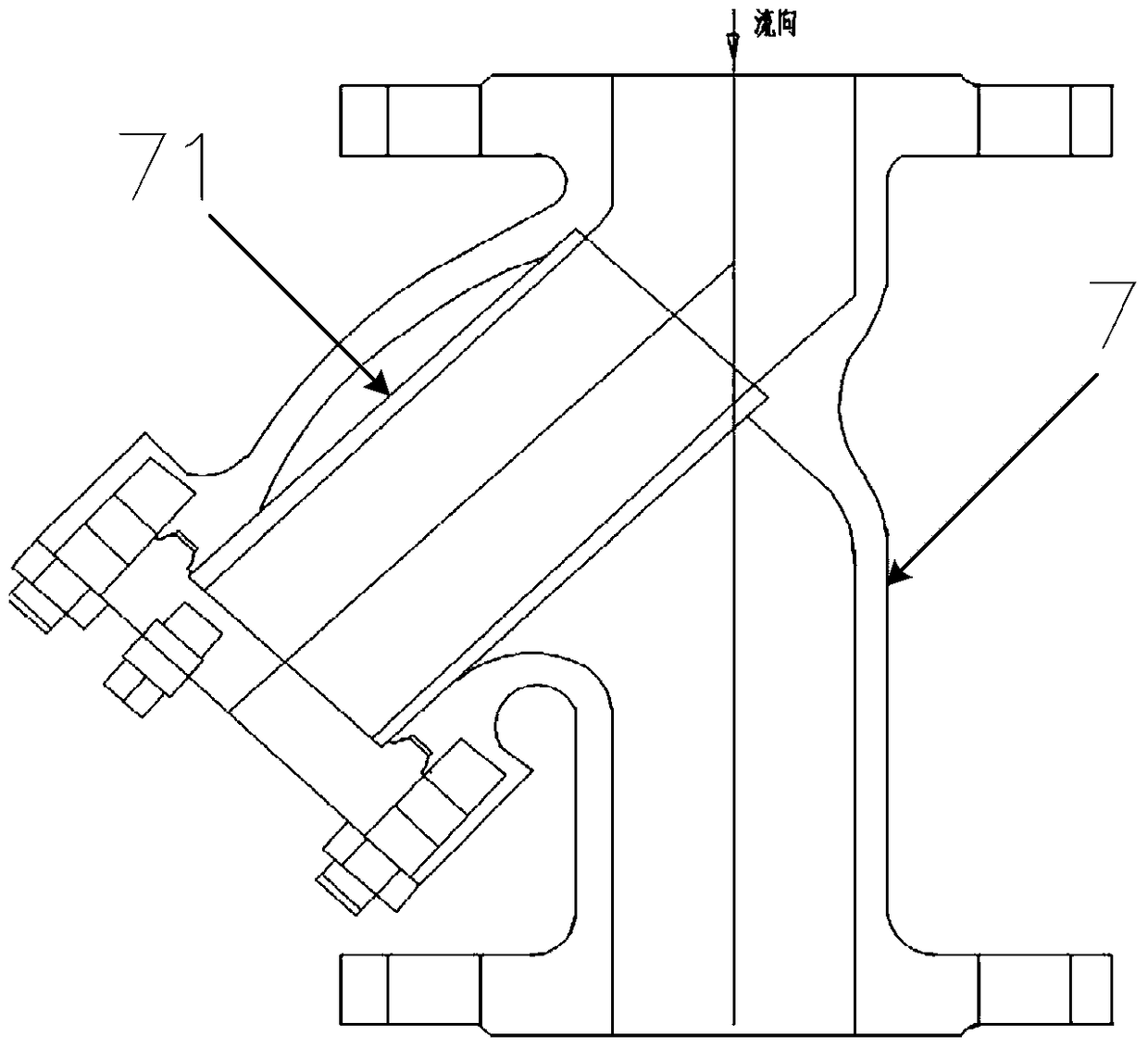

[0029] The diameter of the exhaust pipe 8 at the top of the high-speed filter is 200mm, and the diameter of the hole dug at the front of the top exhaust pipe 8 is 40mm, which is used to connect the inlet end of the eccentric reducing pipe 9, and the diameter of the inlet end of the eccentric reducing pipe 9 = 40mm, the diameter of the outlet end of the eccentric reducing pipe D1 = 25mm, connected to the inlet end of the exhaust diversion pressure relief pipe 11, see Figure 4 . The diameter of the exhaust diversion pressure relief pipe 11 is 25 mm, and is made of corrosion-resistant galvanized steel pipe. The outlet end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com