High-speed milling chatter on-line identification method based on AR model

A high-speed milling and AR model technology, which is applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as poor robustness, sensitivity to changes in working conditions, and time-consuming calculations, so as to reduce the misdiagnosis rate and The effect of missed diagnosis rate, improved sensitivity, improved sensitivity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

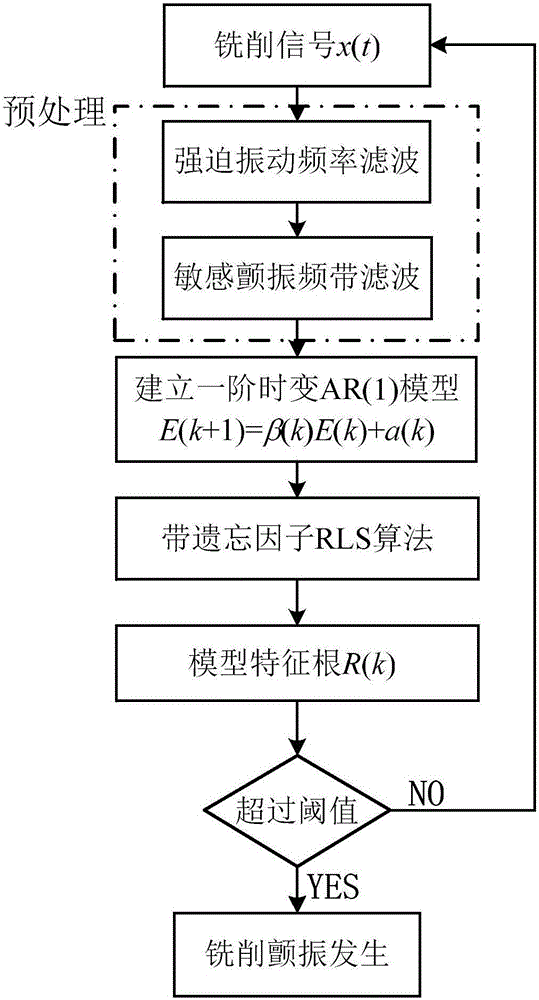

Method used

Image

Examples

Embodiment Construction

[0043] The effectiveness of the present invention in engineering applications is verified below in conjunction with an example, but this example is not intended to limit the present invention.

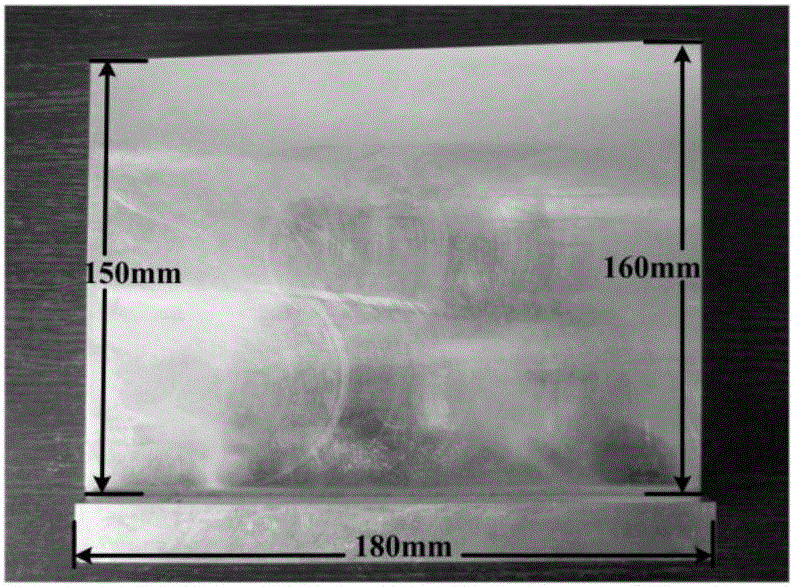

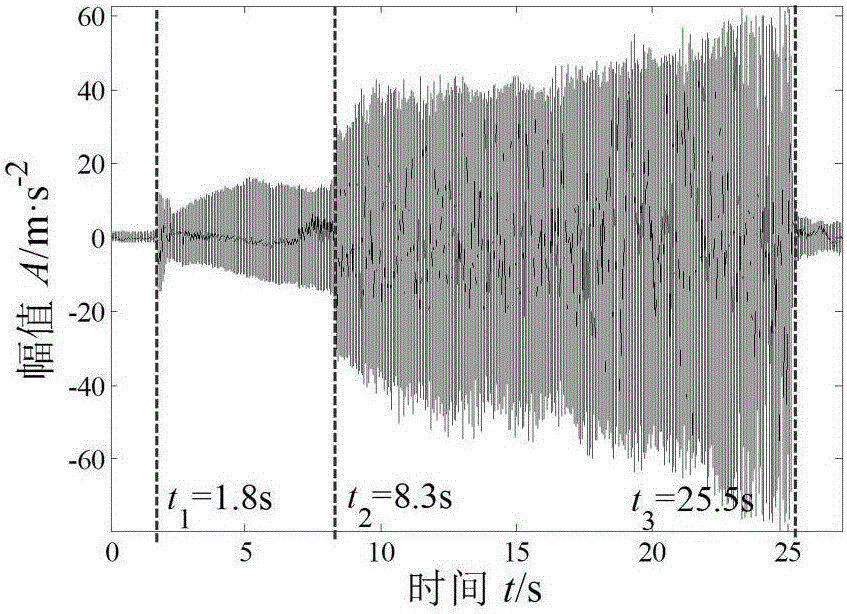

[0044] On-line identification of flutter during high-speed milling of a 7050 aviation aluminum alloy thin-walled plate, the sampling frequency is 10240Hz, and the tool adopts a 3-edged carbide end mill with a diameter of The helix angle of the tool is 45°, the length of the tool body is 75mm, and the overhang length of the tool is 55mm when clamping. The thin-walled board is clamped on the workbench by vise, the thickness is 10mm, and the front dimensions are as follows: figure 2 . The cutting parameters are shown in Table 1. During the milling process, the tool feed rate remains unchanged at 400 mm / min, and the spindle speed in this case is maintained at 9600 r / min (DN value is 1.032×10 6 mm r / min), the tool mills along the direction of the workpiece slope, the axial depth of cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com