Antibacterial bamboo composite material and preparation method

A composite material and bamboo technology, applied in the direction of impregnating wood, wood impregnation, manufacturing tools, etc., can solve the problems of loss of light, yellowing, easy peeling of the surface, etc., to achieve and lasting antibacterial effect, improve antibacterial performance, and good antibacterial effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to the preparation method of the present invention, the bamboo material is pretreated in step 1), for example, the surface of the bamboo material can be polished using a scraper or sandpaper, etc., on the one hand, the surface of the bamboo material is guaranteed to be smooth, and on the other hand, the surface of the bamboo material is guaranteed to be smooth. The surface of the raw material is not polluted by the outside world.

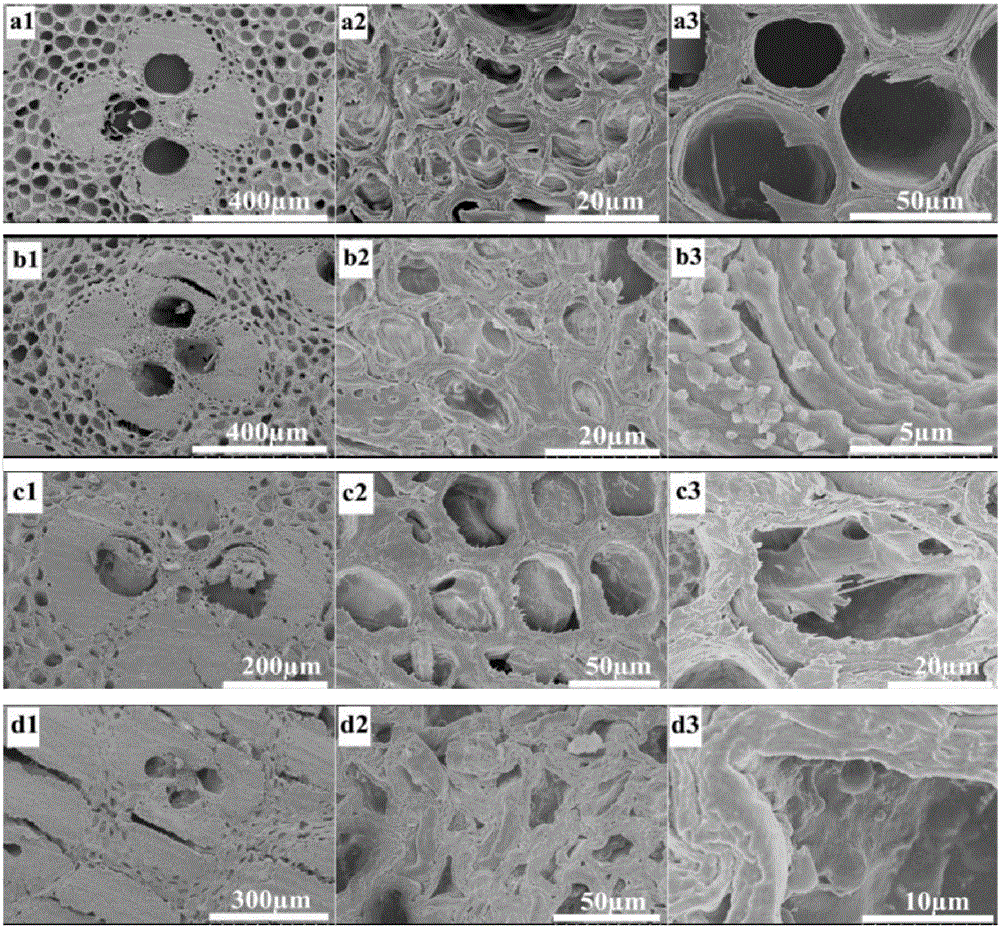

[0028] In step 2), the bamboo raw material treated in step 1) is impregnated, that is, it is completely immersed in the zinc salt mixed solution dispersed with graphene oxide nanosheets, and vacuumed to below 0.01MPa, ultrasonically treated for 10 Minutes make the zinc salt and graphene oxide nanosheets fill the interior of the bamboo material as much as possible. Among them, in order to immerse the zinc salt into the interior of the bamboo material as much as possible, the concentration of the zinc salt in the solution should be as...

Embodiment 1

[0040] Scrape off a thin layer of bamboo (1cm×1cm×1cm) with a spatula, about 1-2mm, then use deionized water and ethanol to vacuum and ultrasonically clean impurities for 30 minutes, dry at 40°C, and completely immerse in 20mL of a mixture of saturated zinc acetate and graphene oxide nanosheets (2g / L) was ultrasonically treated for 10 minutes under vacuum conditions, and after standing for 24 hours, 1mol / L monoethanolamine solution was added dropwise to adjust the pH value of the solution to 10, and ultrasonic treatment was performed under vacuum conditions. Treat for 10 minutes, take out the bamboo pieces after soaking for 24 hours, rinse the impurities on the surface with deionized water, and dry at 60°C;

[0041] Add 1.5 mL of graphene oxide nanosheet aqueous solution with a concentration of 10 g / L into 20 mL of zinc nitrate solution with a concentration of 0.05 mol / L, mix well by ultrasonication for 30 minutes, and add monoethanolamine solution (1 mol / L) dropwise to the sol...

experiment Embodiment 1

[0052] The antibacterial test was carried out on the sample by the inhibition zone method. According to the size of the antibacterial zone around the antibacterial substance, the quality of the anti-mold and antibacterial properties of the sample can be judged. The modified bamboo pieces prepared in Example 1 and Comparative Examples 1 to 3 are tested for Escherichia coli antibacterial properties, and the specific operation process is: prepare the required medium for antibacterial experiments: take by weighing 2.5g of yeast extract powder and 5g of peptone , NaCl 5g, agar powder 7.5g into the conical flask, add 500ml of deionized water, use 1mol / L NaOH to adjust the pH to 7.4, stir for 20min, place it in a 120°C high-pressure steam sterilizer for 20min, and then put Move the culture solution to the ultra-clean bench, divide it into sterile petri dishes, wait for it to naturally solidify into a solid medium, take the twice-diluted E. Incubate at 37°C for 24 hours in a constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com