Micropore ceramic irrigation device and preparation method thereof

A technology of microporous ceramics and sprinklers, which is applied in botany equipment and methods, root waterers, applications, etc., can solve problems such as high working pressure, difficult manufacturing, and high energy consumption, so as to reduce energy consumption and prevent negative The effect of pressure suction mud and root invasion, good anti-clogging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the microporous ceramic emitter of the present invention specifically comprises the following steps:

[0028] (1) Raw material screening: select quartz sand, talc powder, dextrin and silica sol as the main raw materials for preparing microporous ceramic emitters. In order to avoid the interference of other soluble substances in the quartz sand particles, the quartz sand particles were screened, and the quartz sand particles between 150 and 300 mesh were selected and placed in an oven, and dried at 105°C for 12 hours before use.

[0029] (2) Mixing materials: mix quartz sand, talcum powder, dextrin and silica sol according to a certain mass ratio, wherein quartz sand accounts for 50% to 70%, talcum powder accounts for 20% to 40%, dextrin accounts for 5% and Silica sol accounts for 5%. In the mixing process, first mix the quartz sand, talc powder and dextrin according to the above ratio, then add a certain amount of silica sol, put it into a fre...

Embodiment 1

[0034] (1) Raw material screening: select quartz sand, talc powder, dextrin and silica sol as the main raw materials for preparing microporous ceramic emitters. In order to avoid the interference of other soluble substances in the quartz sand particles, the quartz sand particles were screened, and the quartz sand particles between 150 and 300 mesh were selected and placed in an oven, and dried at 105°C for 12 hours before use.

[0035] (2) Mixing: Quartz sand, talcum powder, dextrin and silica sol are mixed according to a certain mass percentage, wherein quartz sand accounts for 60%, talc powder accounts for 30%, dextrin accounts for 5% and silica sol accounts for 5%. In the mixing process, first mix the quartz sand, talc powder and dextrin according to the above ratio, then add a certain amount of silica sol, put it into a frequency conversion planetary ball mill and mill it at a low speed of 200r / min for 10 hours to obtain the inter-tube microporous ceramics Powder required ...

Embodiment 2

[0044] The raw materials for preparing the dispenser in the present invention select quartz sand as the framework material, talcum powder as the sintering aid, dextrin as the adhesion modifier, and silica sol as the adhesive. The selection of the above raw materials is determined on the basis of previous exploration. In this embodiment, the material formulation test in Table 1 was carried out.

[0045] Table 1 Material formula

[0046]

[0047] After material performance testing, it was found that the microporous ceramic emitters prepared by the three formulations in Table 1 can meet the requirements in terms of material properties (such as: open porosity, flexural strength, etc.), but in the hydraulic performance test, it was found that the emitters The flow in the air will gradually decrease with time, and finally approach 0, and blockage occurs (such as Figure 8 ), indicating that the three formulations in Table 1 failed and could not meet the irrigation requirements ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

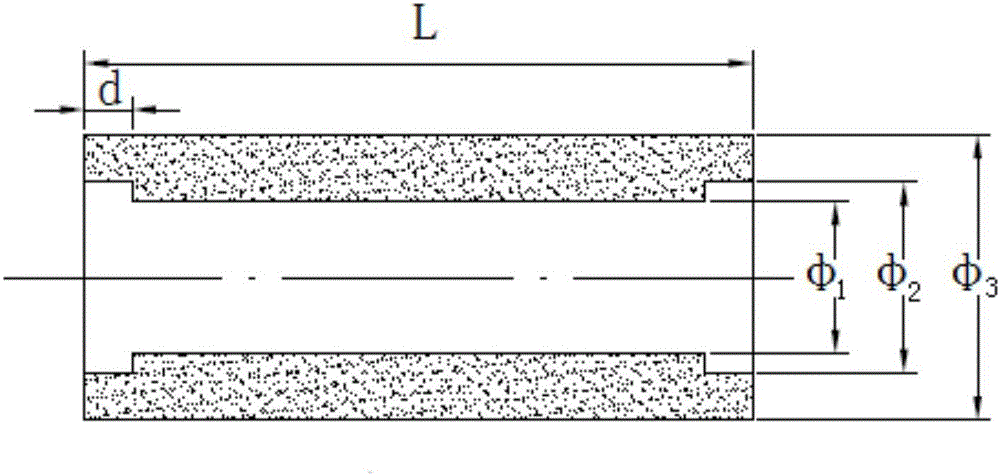

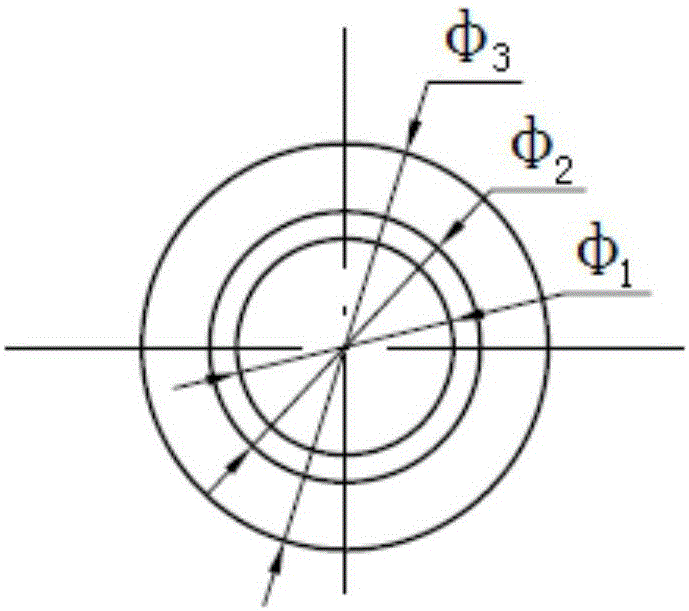

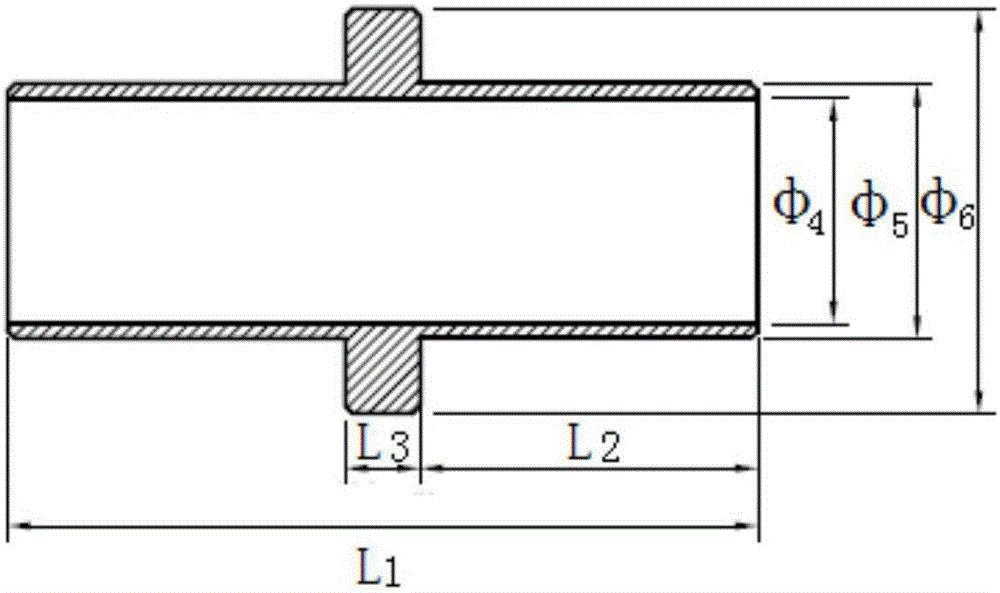

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com