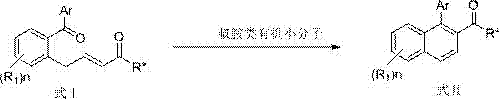

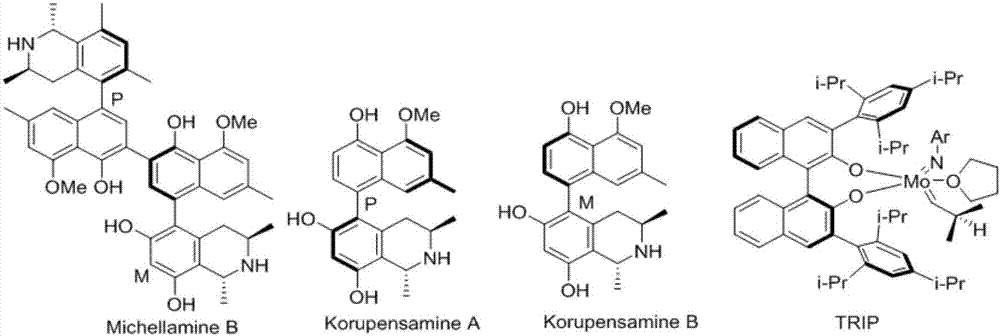

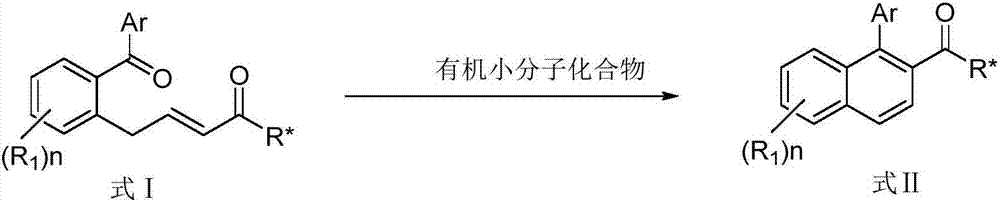

Method for Synthesizing Axial Chiral Biaryl Compounds Using Tertiary Amine Organic Small Molecules

A technology for small molecules and compounds, which is applied in the field of synthesis of axial chiral biaromatic compounds to achieve the effects of good yield, good selectivity and easy modification of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Synthesis of Axial Chiral Biaryl Compounds Shown by Formula Ⅱ-1

[0017]

[0018] Add 110 mg (0.24 mmol) of compound Ⅰ-1, 72.6 μL (0.48 mmol) of 1,8-diazabicycloundec-7-ene (DBU) into 2 mL of tert-butanol, heat to reflux for 24 hours, and use silica gel The product was separated by column chromatography, and the eluent was a mixed solution with a volume ratio of ethyl acetate and petroleum ether of 1:60 to obtain the axial chiral biaryl compound shown in formula II-1 with a yield of 82%. The dr value is 20:80, and the structural characterization data is: 1 H NMR (400MHz, CDCl 3 )δ8.00(dd, J=16.0,8.8Hz,1H),7.91(d,J=8.4Hz,1H),7.89–7.82(m,3H),7.51–7.40(m,2H),7.36(ddd ,J=8,4.8,2.8Hz,1H),7.31–7.21(m,1H),7.20–7.13(m,4H),4.50–4.29(m,1H),1.40(d,J=12Hz,2H) ,1.31(m,1H),1.18–1.09(m,3H),0.84–0.68(m,3H),0.65(d,J=6.4Hz,2H),0.58(dd,J=8.0,4.8Hz,1H ),0.46–0.38(m,6H),0.30–0.18(m,1H),-0.05–-0.15(m,1H),-0.20(dd,J=23.3,12.0Hz,1H); 13 C NMR (100MHz, CDCl 3 )δ167.85,167.52,139.40,139...

Embodiment 2

[0022] Synthesis of Axial Chiral Biaryl Compounds Shown in Formula Ⅱ-2

[0023]

[0024] Add 180 mg (0.35 mmol) of compound Ⅰ-2 and 104 μL (0.7 mmol) of DBU into 3 mL of tert-butanol, heat to reflux for 24 hours, and separate the product by silica gel column chromatography. The eluent is the volume of ethyl acetate and petroleum ether. Mixed solution with a ratio of 1:10, the axial chiral biaryl compound shown in formula II-2 was obtained, the yield was 80%, the dr value was 27:73, and the structural characterization data was: 1 HNMR (400MHz, CDCl 3)δ7.99–7.86(m,3H),7.80(d,J=8.4Hz,1H),7.51(dd,J=16.4,8.8Hz,1H),7.40(dd,J=11.6,5.6Hz,1H ),7.35(d,J=6.8Hz,1H),7.27(d,J=7.2Hz,1H),7.25–7.20(m,2H),7.18(s 1H),6.57(s,1H),6.46( s,1H),4.42(td,J=10.8,4Hz,1H),3.99(s,3H),3.41(d,J=23.6Hz,3H),1.39(m,4H),1.20–1.12(m, 1H),0.88(m,1H),0.81–0.72(m,1H),0.70(d,J=6.4Hz,2H),0.63(d,J=6Hz,1H),0.55–0.43(m,6H) ,0.29(t,J=9.6Hz,1H),0.05–-0.02(m,1H),-0.05(s,1H),-0.21(dd,J=23.2,12.0Hz,1H); 13 C NMR (100M...

Embodiment 3

[0028] Synthesis of Axial Chiral Biaryl Compounds Shown by Formula Ⅱ-3

[0029]

[0030] Add 100 mg (0.24 mmol) of compound Ⅰ-3 and 108 μL (0.72 mmol) of DBU into 2 mL of tert-butanol, heat to reflux for 12 hours, and separate the product by silica gel column chromatography. The eluent is the volume of ethyl acetate and petroleum ether. The mixed solution with a ratio of 1:100 can obtain the axial chiral biaryl compound shown in formula II-3, the yield is 83%, the dr value is 18:82, and the structural characterization data are: 1 H NMR (400MHz, CDCl 3 )δ8.01(dd, J=19.2,8.0Hz,1H),7.93(d,J=9.2Hz,2H),7.58–7.53(m,1H),7.37(m,4H),7.27(m,1H ),7.11(dd,J=18.4,7.6Hz,1H),4.73(dtd,J=15.2,10.8,4.4Hz,1H),1.98(d,J=14.4Hz,3H),1.78–1.70(m, 2H),1.62(m,2H),1.38(m,1H),1.13–0.93(m,2H),0.89–0.67(m,11H),0.46(dd,J=23.6,12Hz,1H); 13 C NMR (100MHz, CDCl 3 )δ167.93,140.58,138.95,138.86,137.02,136.64,134.78,134.62,132.45,132.25,129.63,129.42,129.34,128.77,127.95,127.87,127.55,127.52,127.41,127.37,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com