Preparation method of Ibrutinib drug impurity

A technology of ibrutinib and compound, applied in the field of drug synthesis, can solve the problems such as no process impurity report yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

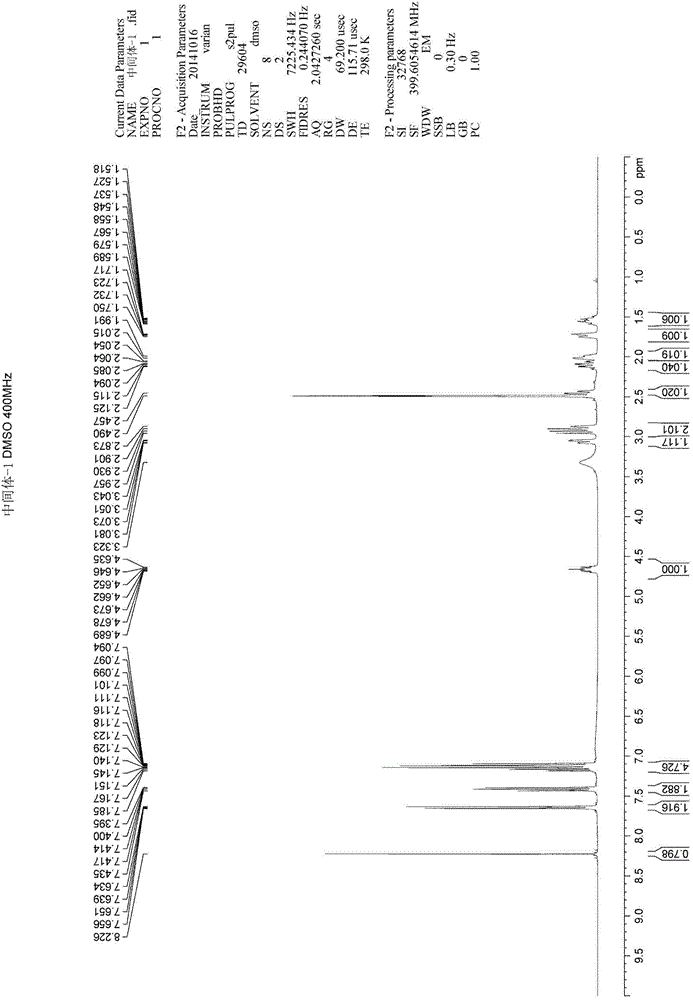

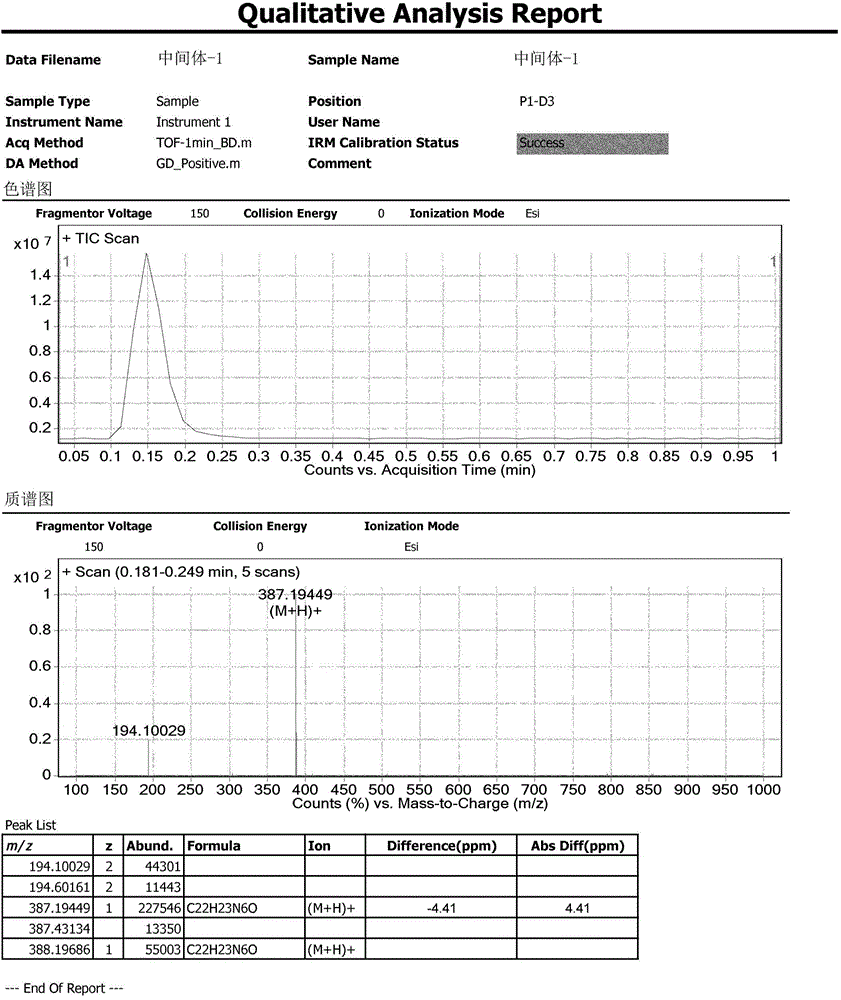

[0066] Example 1: Intermediate-1: (R)-3-(4-phenoxyphenyl)-1-(piperidin-3-yl)-1H-pyrazolo[3,4-d]pyrimidine- Synthesis of 4-amine (YLTN-1)

[0067] Add 155mL tetrahydrofuran to a 500mL reaction flask, and add 3-(4-phenoxyphenyl)-1H-pyrazol[3,4-D]pyrimidin-4-amine (SM1) (5g, 1eq) sequentially under stirring , (S)-1-tert-butoxycarbonyl-3-hydroxypiperidine (SM2) (4.97g, 1.5eq), triphenylphosphine (13g, 3.0eq). Under temperature control at 25° C., a solution of diisopropyl azodicarboxylate in tetrahydrofuran (dissolve 10 g, 3.0 eq of diisopropyl azodicarboxylate in 10 mL of tetrahydrofuran) was added dropwise within 30 minutes. After the dropwise addition was completed, the temperature was controlled at 25° C., and the reaction was continued for 5 hours (TLC monitoring: ethyl acetate:methanol=10:1). Stirring and distillation under reduced pressure. The temperature was controlled at 15°C, and 30 mL of concentrated hydrochloric acid was added dropwise to the residue for 30 minutes....

Embodiment 2

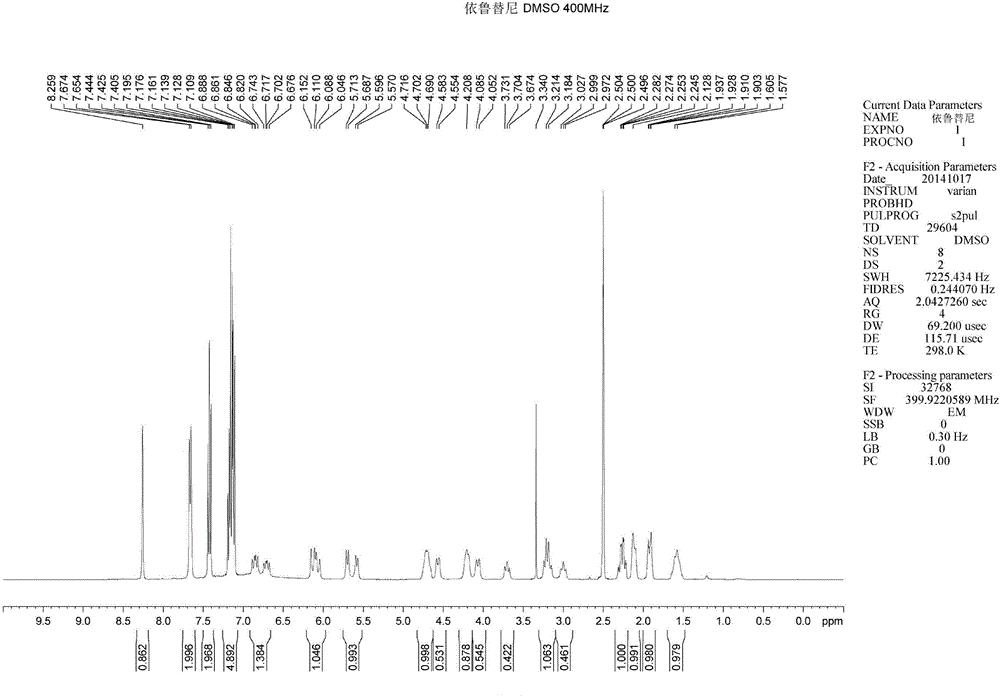

[0068] Embodiment 2: Preparation of Ibrutinib

[0069] Under nitrogen protection, 50 mL of dichloromethane, Intermediate-1 (5 g, 1 eq), and N, N-diisopropylethylamine (2 g, 1.2 eq) were sequentially added into a 100 mL three-necked flask. Under the condition of temperature control at -10°C, start to add the dichloromethane solution of acrylic anhydride (1.96g, 1.2eq) dropwise for 30 minutes. Until the reaction of the raw materials was complete (TLC detection, methanol: ethyl acetate: triethylamine = 1:5:0.05). The reaction solution was washed with 200 mL of 5% citric acid aqueous solution, the water phase was removed, concentrated and evaporated to remove dichloromethane. The crude product of Ibrutinib: 3.63g. 1H-NMR (400Mz, DMSO-d 6 ( m, 1H), 5.570~5.713(m, 1H), 4.690~4.716(m, 1H), 4.554~4.583(m, 0.5H), 4.208(m, 1H), 4.052~4.085(m, 0.5H), 3.674~3.731(m, 0.5H), 3.184~3.214(m, 1H), 2.972~3.027(m, 0.5H), 2.245~2.282(m, 1H), 2.128(m, 1H), 1.903~1.937(m , 1H), 1.577~1.605(...

Embodiment 3

[0070] Example 3: Impurity A: (R)-1-(3-(4-amino-3-(4-phenoxyphenyl)-1H-pyrazolo[3,4-d]pyrimidin-1-yl Synthesis of 1-piperidin-1-yl)-3-chloropropyl-1-one.

[0071] Under nitrogen protection, 50ml of dichloromethane was added to a 100mL three-necked flask, and Intermediate-1 was added sequentially under stirring: (R)-3-(4-phenoxyphenyl)-1-(piperidin-3-yl )-1H-pyrazol[3,4-d]pyrimidin-4-amine (YLTN-1) (1.00g, 1eq), N, N-diisopropylethylamine (0.40g, 1.2eq), cooled to -20~-10°C, start to add 3-chloropropionyl chloride (1.46g, 1eq) dropwise. After the dropwise addition, the solution turns from cloudy to clear. Continue to stir for 20-30 minutes. LC-MS detects that the raw materials disappear, and distills under reduced pressure. , dichloromethane was distilled until no fraction was distilled off, and the crude product was purified by column chromatography, the elution ratio was: methanol: ethyl acetate=1:10, a total of 400 mL of the eluent was collected, distilled under reduced pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com