Method for refining high-purity tedizolid phosphate

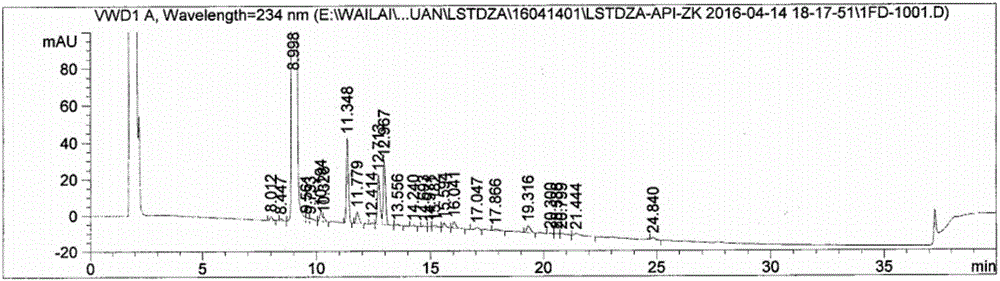

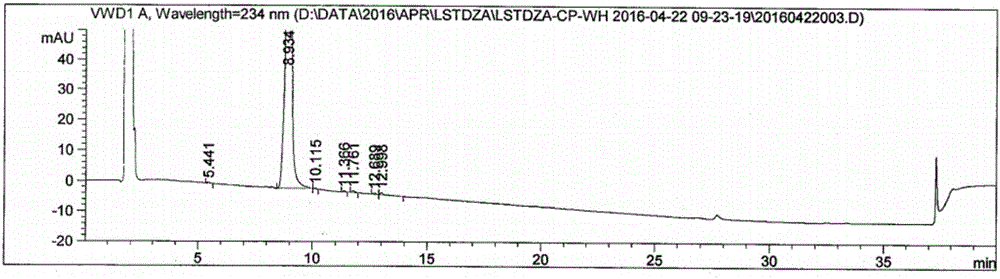

A technology of tedizolid phosphate and a refining method, applied in the field of medicine, can solve the problems of less tedizolid phosphate, large amount of solvent, large product impurity content, etc., and achieves the effects of good stability, stable process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

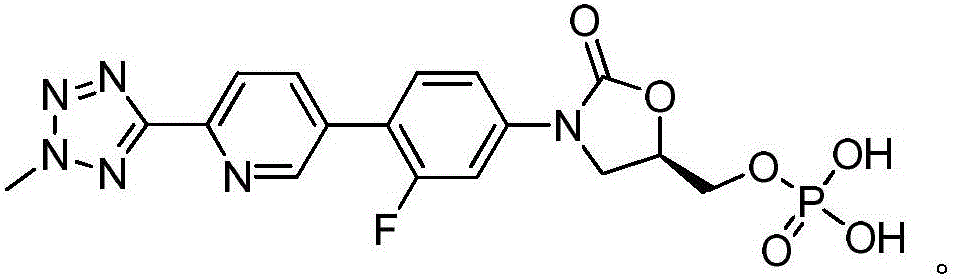

[0053] (1) Add 10g of crude tedizolid phosphate and 100ml of dimethyl sulfoxide into the reaction flask, stir, heat to about 50°C, dissolve and clarify, add a mixed solvent of 10ml of purified water and 100ml of methanol to it, and heat up to 70°C , stirred for 9 hours, cooled to 10°C, stirred for 0.5 hours, and filtered to obtain a filter cake;

[0054] (2) Transfer the filter cake obtained in step (1) into the reaction flask, add 50ml of purified water, stir, slowly add 3.85wt% sodium hydroxide aqueous solution, adjust the pH of the solution to 7.8, then slowly add the above solution to 300ml In acetone, crystallize for 0.5 hours, filter with suction, add the obtained filter cake into a mixed solvent of 120ml of purified water and 120ml of tetrahydrofuran, stir and dissolve, quickly adjust the pH to 1.5 with 2N hydrochloric acid aqueous solution, stir for 1 hour, and filter with suction to obtain the filter cake ;

[0055] (3) Dissolve the filter cake finally obtained in st...

Embodiment 2

[0058] (1) Add 10g of crude tedizolid phosphate and 100ml of dimethyl sulfoxide into the reaction flask, stir, heat to about 50°C, dissolve and clarify, add a mixed solvent of 10ml of purified water and 100ml of ethanol to it, and heat up to 70°C , stirred for 12 hours, cooled to 10°C, stirred for 0.5 hours, and filtered to obtain a filter cake;

[0059] (2) Transfer the filter cake obtained in step (1) into the reaction flask, add 50ml of purified water, stir, slowly add 3.85wt% sodium hydroxide aqueous solution, adjust the pH of the solution to 8.0, then slowly add the above solution to 350ml In acetone, crystallize for 0.5 hours, and filter with suction, add the obtained filter cake into a mixed solvent of 120ml of purified water and 120ml of tetrahydrofuran, stir and dissolve, quickly adjust the pH to 1.2 with 2N hydrochloric acid aqueous solution, stir for 1 hour, filter, and filter with suction to obtain filter cake;

[0060] (3) Dissolve the filter cake finally obtaine...

Embodiment 3

[0063] (1) Add 10g of crude tedizolid phosphate and 100ml of dimethyl sulfoxide into the reaction flask, stir, heat to about 50°C, dissolve and clarify, add a mixed solvent of 10ml of purified water and 100ml of methanol to it, and heat up to 70°C , stirred for 8 hours, cooled to 10°C, stirred for 0.5 hours, and filtered to obtain a filter cake;

[0064] (2) Transfer the filter cake obtained in step (1) into the reaction flask, add 50ml of purified water, stir, slowly add 3.85wt% sodium hydroxide aqueous solution, adjust the pH of the solution to 7.7, then slowly add the above solution to 350ml In tetrahydrofuran, crystallize for 0.5 hours, and filter with suction, add the obtained filter cake into a mixed solvent of 120ml of purified water and 120ml of tetrahydrofuran, stir and dissolve, quickly adjust the pH to 1.0 with 2N hydrochloric acid aqueous solution, stir for 1 hour, filter, and filter with suction to obtain filter cake;

[0065] (3) Dissolve the filter cake finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com