Chemical-resistant industrial anti-corrosive water paint and preparation method thereof

A chemical-resistant and industrial technology, applied in the field of water-based anti-corrosion coatings and coatings, can solve the problems of water-based paint film hardness is not high enough, poor chemical resistance, easy to scratch, etc., to achieve less impact on health, wear resistance and Improved scratch resistance and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

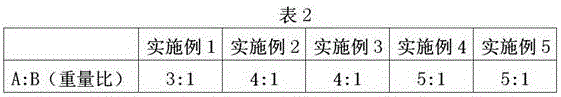

[0024] Industrial anti-corrosion water paint is a two-component water-based paint, which is composed of A component and B component. The first two components are stored separately. During construction, the A component and B component are in a weight ratio of 3 to 5:1 Mix and serve.

[0025] Component A is mainly composed of base material, additives and pigments and fillers. The base material is water-based polyurea resin, using polyaspartate resin of model F420 from Shenzhen Feiyang Industrial Co., Ltd. and polyurethane polyurea resin of model Desmophen N1420 from Bayer, Germany, mixed according to the weight ratio of 2:1 be made of.

[0026] Component B is an aliphatic polyisocyanate-type solvent-free curing agent, which is a product of Desmodur N 3300 from Bayer, Germany.

[0027] Weigh the base materials, additives and pigments and fillers in different proportions by weight to produce component A, and the specific proportions are shown in Table 1 below.

[0028]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com