Deep oil displacement and profile control agent for oil deposit and preparation method thereof

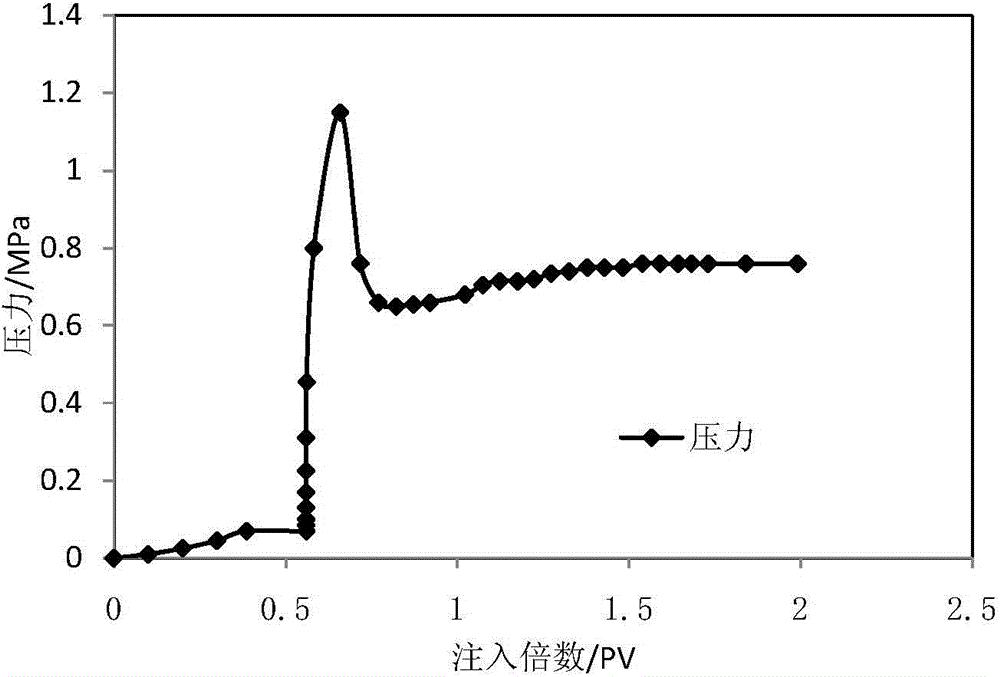

A technology of control and displacement agent and deep part, which is applied in the field of preparation of new high-efficiency reservoir control and displacement agent, which can solve problems such as ineffective production wells, difficult injection into reservoirs, chemical agent slug, etc., and achieve excellent plugging and profile control effects , Improve oil displacement efficiency, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Viscoelastic polymer particles are prepared by the following steps:

[0044] a. Prepare a mass concentration of 20% acrylamide (AM) with deionized water;

[0045] b. remove the oxygen in the acrylamide solution of step a through high-purity nitrogen;

[0046] c. Add sodium allylsulfonate and hexadecyldimethylallyl ammonium chloride with a mass ratio of 1:1 to the acrylamide solution in step b, so that the mass concentration in the acrylamide solution is 10 %, add N,N-methylenebisacrylamide, so that its mass concentration in the acrylamide solution is 0.001%, and add a sodium bisulfite-ammonium persulfate redox initiator with a mass ratio of 2:1 to make it The mass concentration in the acrylamide solution is 0.005%, mix well, take out the reaction product after reacting for 8 hours, put it in a drying oven and dry it at 60°C;

[0047] d. After drying, it is granulated by a granulator, and 30-mesh granules are screened out through a screen to obtain viscoelastic polymer...

Embodiment 2

[0053] Viscoelastic polymer particles are prepared by the following steps:

[0054] a. Prepare a mass concentration of 30% acrylamide (AM) with deionized water;

[0055] b. remove the oxygen in the acrylamide solution of step a through high-purity nitrogen;

[0056] c. Add sodium allylsulfonate and hexadecyldimethylallyl ammonium chloride with a mass ratio of 1:1 to the acrylamide solution in step b, so that the mass concentration in the acrylamide solution is 5 %, add N,N-methylenebisacrylamide, so that its mass concentration in the acrylamide solution is 0.002%, and add a sodium bisulfite-ammonium persulfate redox initiator with a mass ratio of 1:1 to make it The mass concentration in the acrylamide solution is 0.01%, mix well, take out the reaction product after reacting for 6 hours, put it in a drying oven and dry it at 80°C;

[0057] d. After drying, it is granulated by a granulator, and 100-mesh particles are screened out through a screen to obtain viscoelastic polymer...

Embodiment 3

[0063] Viscoelastic polymer particles are prepared by the following steps:

[0064] a. Prepare a mass concentration of 25% acrylamide (AM) with deionized water;

[0065] b. remove the oxygen in the acrylamide solution of step a through high-purity nitrogen;

[0066] c. Add allyl sodium sulfonate and hexadecyldimethylallyl ammonium chloride with a mass ratio of 1:1 to the acrylamide solution in step b, so that the mass concentration in the acrylamide solution is 7 %, N, N-methylenebisacrylamide is added to make the mass concentration in the acrylamide solution 0.0015%, and a sodium bisulfite-ammonium persulfate redox initiator with a mass ratio of 1.5:1 is added to make it The mass concentration in the acrylamide solution is 0.007%, mix well, take out the reaction product after reacting for 7 hours, put it in a drying oven and dry it at 70°C;

[0067] d. After drying, it is granulated by a granulator, and 70-mesh particles are screened out through a screen to obtain viscoelas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com