Method for separating and purifying recombinant bacillus subtilis fibrinolytic enzyme

A Bacillus subtilis, separation and purification technology, applied in the field of protein separation and purification, can solve the problems of Bacillus subtilis plasmin separation and purification, high purification cost, low solid fermentation content, etc., achieves huge market application value, and is easy to industrialize amplification , the effect of huge development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

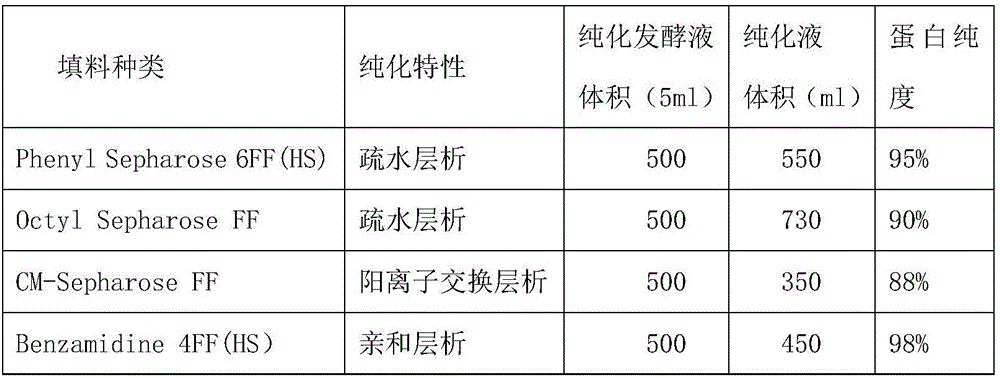

[0028] As shown in Table 1, according to the characteristics of the recombinant Bacillus subtilis plasmin protein, according to the purification efficiency and final protein purification purity, the types of phenyl sepharose series hydrophobic fillers can be selected from the following types: Phenyl Sepharose 6FF (HS), Octyl Sepharose FF, CM-Sepharose FF, Benzamidine 4FF (HS), Phenyl Sepharose 6FF (HS) and Benzamidine 4FF (HS) have a purity of more than 95%. Considering the cost factor, the final comprehensive comparison selection determines that the purified filler is Phenyl Sepharose 6FF(HS). This embodiment is illustrated by taking Phenyl Sepharose6FF (HS) as an example.

[0029] A method for separating and purifying recombinant Bacillus subtilis plasmin, comprising the following steps:

[0030] 1) Hydrophobic chromatography: choose Phenyl Sepharose 6FF (HS) to fill the chromatographic column, the mobile phase buffer is liquid A and liquid B, adjust the purification equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com