Tri-channel asynchronous drafting, clustering and spinning device, colored spun yarn three-primary-color mixing effect regulation and control device and mixed color section colored yarn

A drafting device, three-channel technology, applied in the spinning machine, drafting equipment, yarn and other directions, can solve the problems of deviation from the set value, unable to achieve precise control of mixed color, precise control of mixed color difference, difference, etc., to achieve stable shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

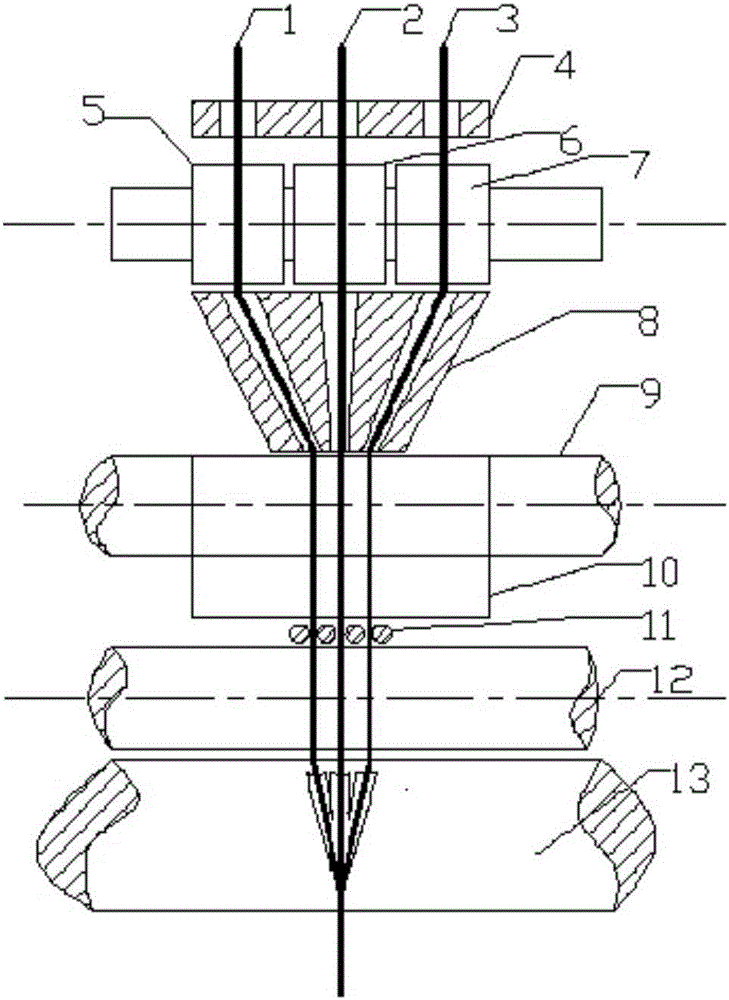

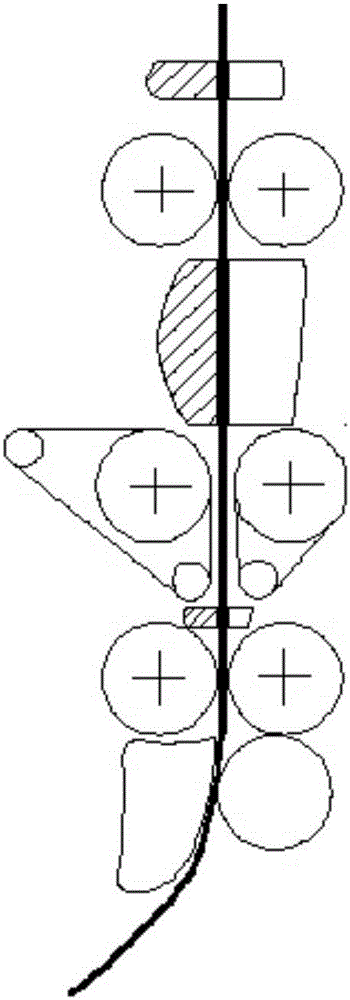

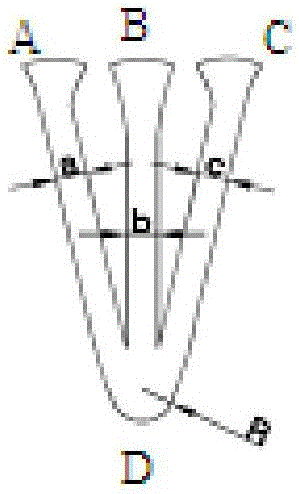

[0037] like figure 1 , figure 2 As shown, the three-channel asynchronous drafting bundle spinning device of the present invention includes a three-channel asynchronous drafting device, a three-channel yarn guiding device and a three-channel gathering device; the three-channel asynchronous drafting device includes a combined rear roller, a middle Roller 9 and front roller 12, the combined rear roller is made up of the first rear roller 5, the second rear roller 6 and the third rear roller 7 driven independently, and the draft apron 10 is set on the middle roller 9; the three-channel guide The yarn device includes a three-eye rear bell mouth 4, a three-channel yarn guide 8, and a yarn guide rod 11; the three-eye rear bell mouth 4 is arranged at the input end of the combined rear roller, and the three-eye rear bell mouth 4 has three primary colors. Three holes through which the rovings pass; the three-channel yarn guide 8 is arranged between the combined rear roller and the mid...

Embodiment 2

[0074] Select Xinjiang fine-staple cotton or long-staple cotton, dyed red, yellow, and blue respectively, and produce it into roving according to the carding or combing process. The draft-twisting-winding system feeds rovings of three colors simultaneously to one spinning spindle. The three-channel asynchronous drafting cluster spinning device can perform asymmetrical asynchronous drafting on three rovings according to the color mixing ratio, and the three bundles of whiskers are then gathered through the cluster and the accumulation groove and then twisted to form segmented colored yarns with varying color mixing ratios.

[0075] Set thick yarn density T s =350tex, segment color yarn density T y =25tex, twist N z =760 twist / m, spindle speed N D =7600 rev / min, yarn twisting spiral period length h=1 / N z =1000 / 760=1.32mm, front roller pull-out line speed V q = 10 m / min. The implementation steps are as follows:

[0076] (1) The color mixing ratio and segment length design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com