Recycling system for waste heat generated in fatty acid production process

A production process and waste heat recovery technology, applied in heat pumps, steam generation, lighting and heating equipment, etc., can solve problems such as environmental pollution and energy waste, and achieve the effects of reducing production costs, improving the environment, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

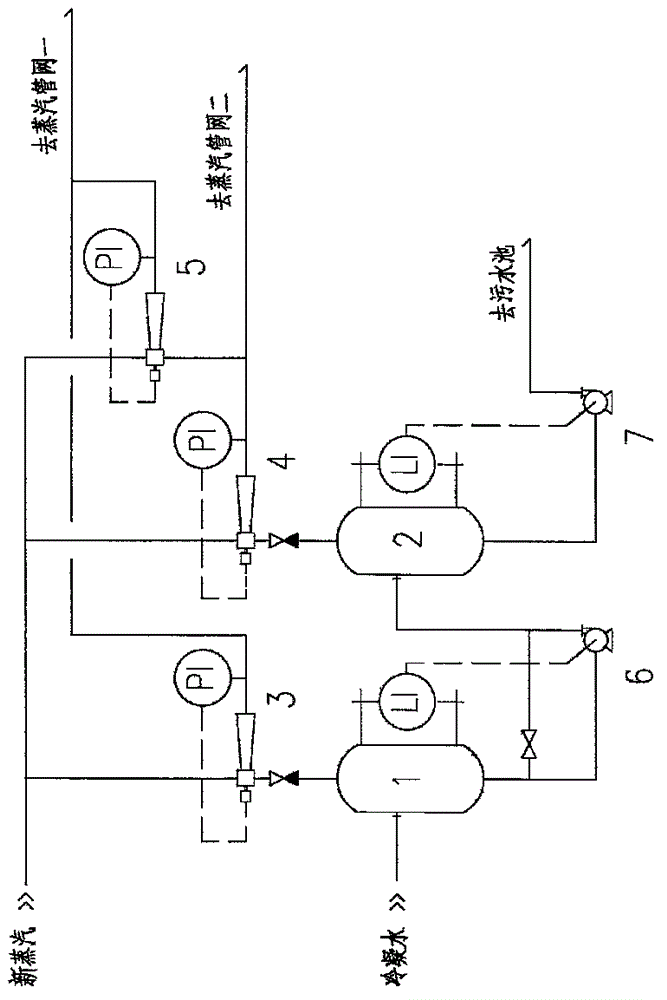

[0016] Attached below figure 1 and specific embodiments, further explain the present invention in detail. It should be noted that the system of the present invention is also applicable to waste heat recovery in other industries, such as petrochemical, daily chemical, textile printing and dyeing, food, medicine, building materials and other industries.

[0017] Such as figure 1 As shown, a fatty acid production process waste heat recovery system includes flash tanks 1-2, steam jet heat pumps 3-5, and high-temperature condensate pumps 6-7.

[0018] The steam condensate inlet of the flash tank 1 is connected to the high-temperature steam condensate discharge outlet of the fatty acid production device, the flash steam outlet of the steam tank 1 is connected to the low-pressure steam port of the steam jet heat pump 3 through a check valve, and the mixed steam outlet of the steam jet heat pump 3 passes through the steam The pipe network 1 is connected to the steam-using equipment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com