Method for analyzing ludwigite through X-ray fluorescence powder tableting method

A technology of maficite and fluorescent powder, which is applied in the field of chemical inspection, can solve the problems of environmental pollution of chemical reagents and high labor intensity of personnel, and achieve the effects of low environmental pollution, high accuracy and low inspection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below, but it should be noted that the implementation of the present invention is not limited to the following embodiments.

[0027] A method for analyzing boron maficite by X-ray fluorescence powder pressing method, comprising the following steps:

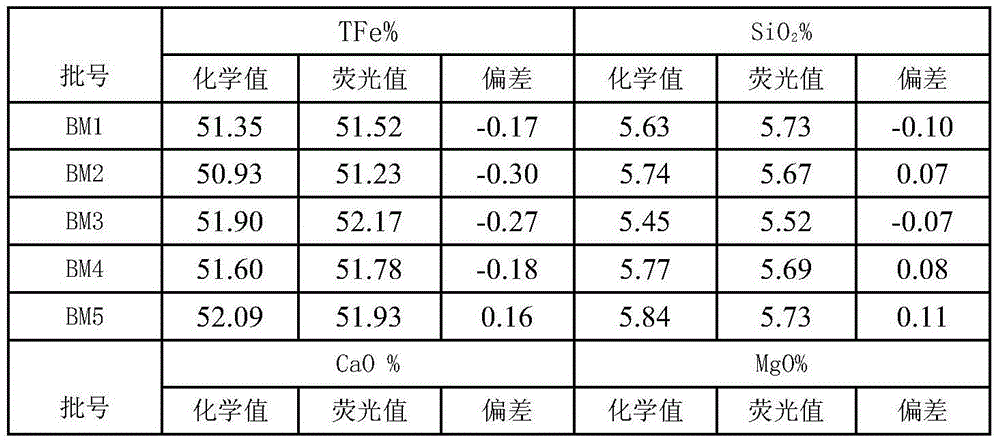

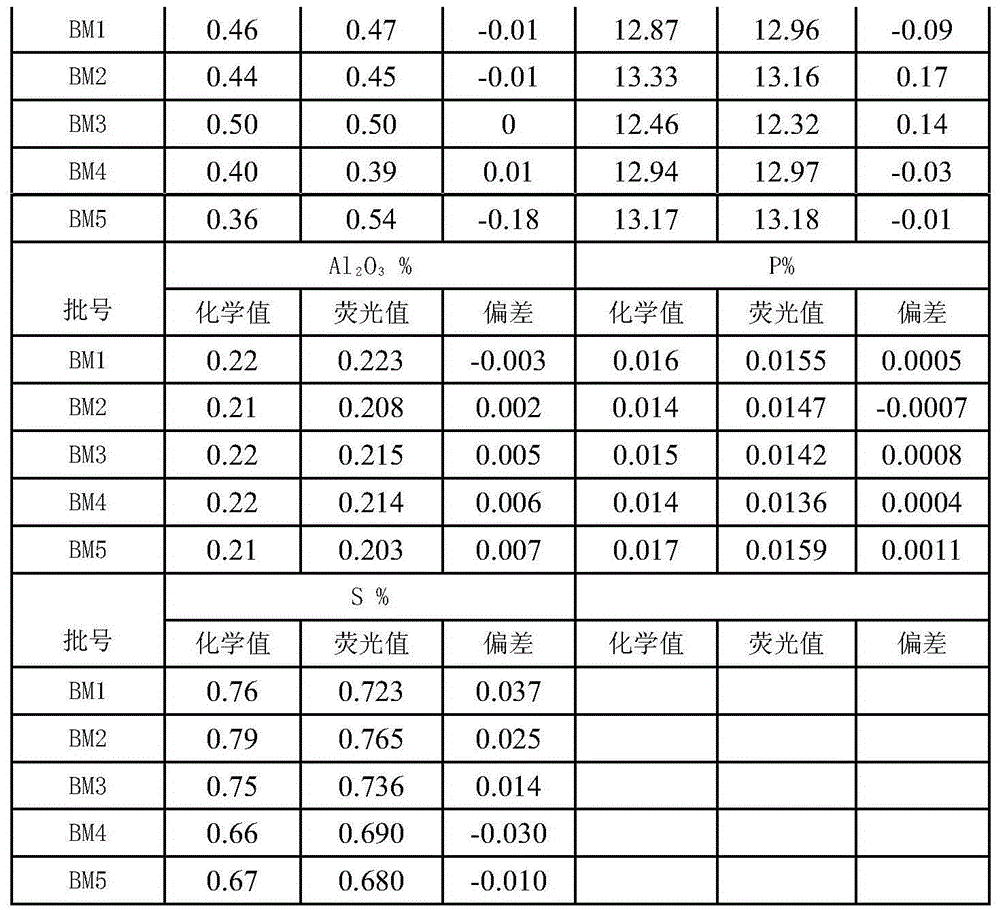

[0028] 1) Establish a standard curve with maficite with known content of each element, use an X-ray fluorescence spectrometer to measure the emission intensity of the sample elements, use a series of internal control standard samples to measure the emission intensity of each element, and combine each element in the sample The mass percentage content of the sample element content is obtained, and a straight line associated with the sample element content and its linear equation are obtained;

[0029] 2) Determining the maficite to be measured, using an X-ray fluorescence spectrometer to measure the emission intensity of the sample elements, and using the obtained linear equat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com