Method for detecting organochlorine residues in azo dye product

An azo dye and organochlorine technology, which is used in measurement devices, material separation, and analysis of materials, etc., can solve the problems of inability to batch operation, extract many impurities, and result interference, and achieve the protection of the injection port and chromatographic column, and purification effects. Good, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

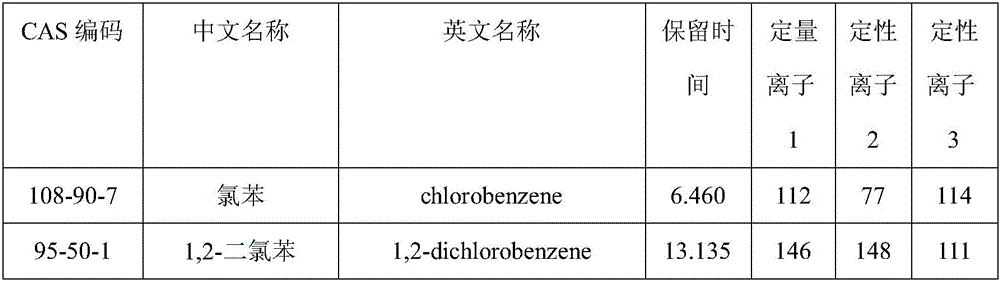

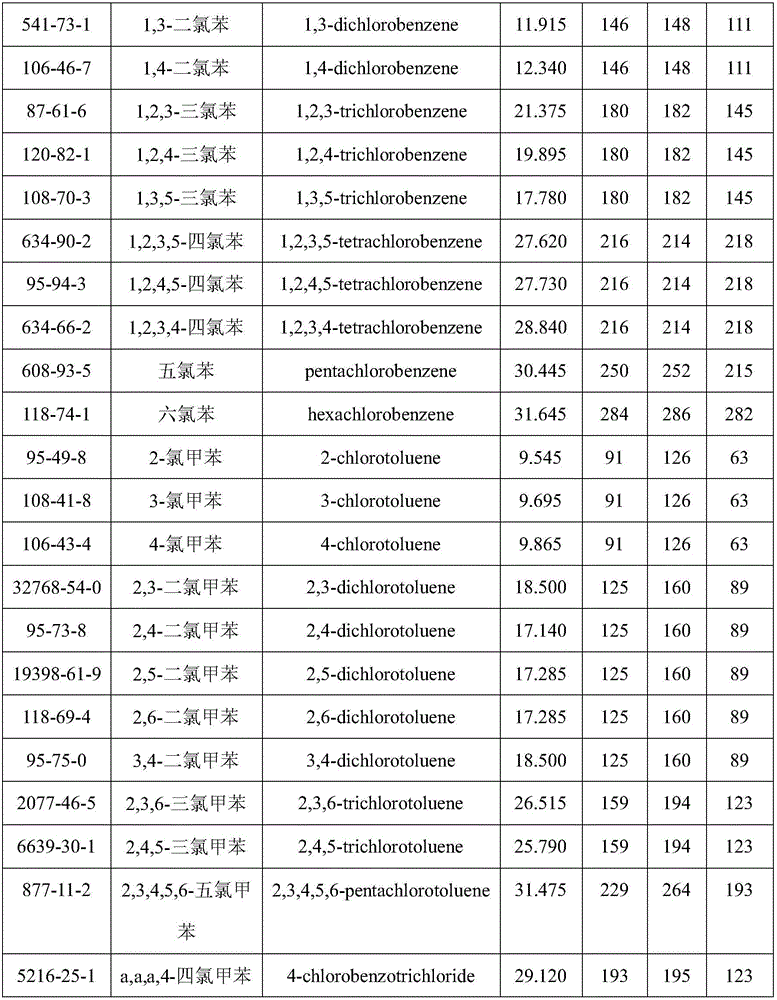

Image

Examples

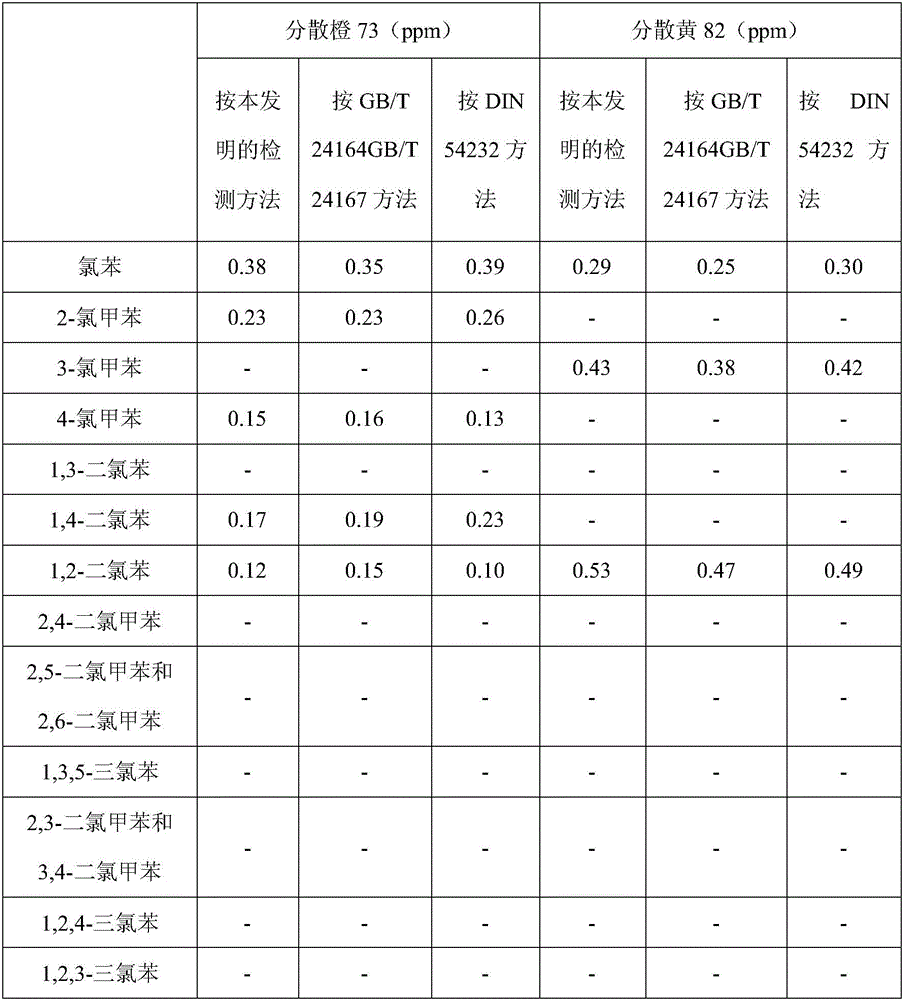

Embodiment 1

[0044] (1) Sample preparation:

[0045] Weigh 0.5g of Disperse Orange 73 azo dye product (accurate to 0.0001g) and place the dye sample to be tested in a conical flask with a ground stopper.

[0046] (2) Reductive cracking:

[0047] Add 25mL citrate buffer solution (0.06mol / L aqueous solution, pH=6) to the Erlenmeyer flask, seal the Erlenmeyer flask and preheat it at 60°C for 30min, then add 10.0mL sodium dithionite solution (200g / L ), shake vigorously and keep at 60°C for 30 minutes, and shake it from time to time to fully restore it. After reduction, take out the Erlenmeyer flask, cool it down to room temperature quickly with cold water, and adjust the pH to 8 with anhydrous sodium carbonate solution (200g / L). (3) Extraction:

[0048]In a separatory funnel, extract with chloroform three times, using 30 mL of chloroform each time, centrifuge for 5 minutes during extraction, then let stand to separate layers, take the lower layer and put it into a round bottom flask.

[00...

Embodiment 2

[0055] (1) Sample preparation:

[0056] Weigh 0.5g of the disperse yellow 82 azo dye product (accurate to 0.0001g) and place the dye sample to be tested in a conical flask with a ground stopper.

[0057] (2) Reductive cracking:

[0058] Add 25mL citrate buffer solution (0.08mol / L aqueous solution, pH=6) to the Erlenmeyer flask, seal the Erlenmeyer flask and preheat it at 50°C for 40min, then add 10.0mL sodium dithionite solution (200g / L ), shake vigorously and keep it at 50°C for 40 minutes, and shake it from time to time to fully restore it. After reduction, take out the Erlenmeyer flask, cool it down to room temperature quickly with cold water, and adjust the pH to 9 with anhydrous sodium carbonate solution (200g / L).

[0059] (3) Extraction:

[0060] In a separatory funnel, extract with n-hexane 3 times, using 30 mL of n-hexane each time, centrifuge for 5 minutes during extraction, then let stand to separate layers, take the lower layer and put it into a round bottom flas...

Embodiment 3

[0066] (1) Sample preparation:

[0067] Weigh 0.5g of the disperse black ECO azo dye product (accurate to 0.0001g) and place the dye sample to be tested in a conical flask with a ground stopper.

[0068] (2) Reductive cracking:

[0069] Add 25mL citrate buffer solution (0.1mol / L aqueous solution, pH=6) into the Erlenmeyer flask, seal the Erlenmeyer flask and preheat it at 80°C for 20min, then add 10.0mL sodium dithionite solution (200g / L ), shake vigorously and keep it at 80°C for 20 minutes, and shake it from time to time to fully restore it. After reduction, take out the Erlenmeyer flask, cool it down to room temperature quickly with cold water, and adjust the pH to 8 with anhydrous sodium carbonate solution (200g / L).

[0070] (3) Extraction:

[0071] In a separatory funnel, extract with dichloromethane 3 times, using 30 mL of dichloromethane each time, centrifuge for 5 minutes during extraction, then let stand to separate layers, take the lower layer and put it into a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com