Touch screen, touch display assembly and electronic equipment

A touch screen and display module technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems such as glare interference, reduce the impact, increase light transmittance, improve contrast and clarity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

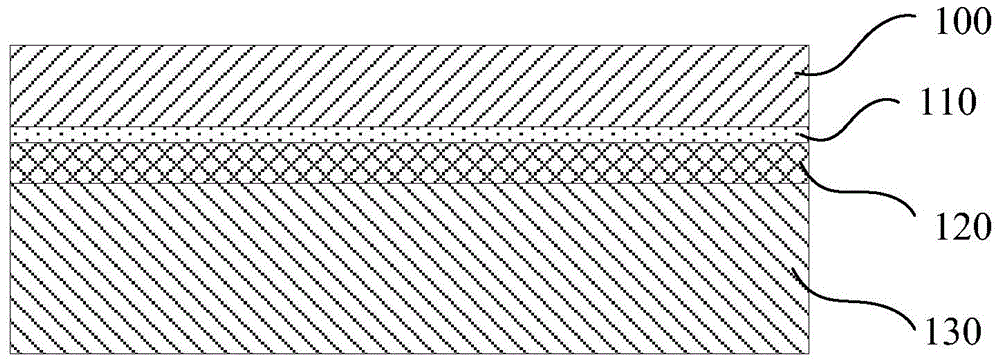

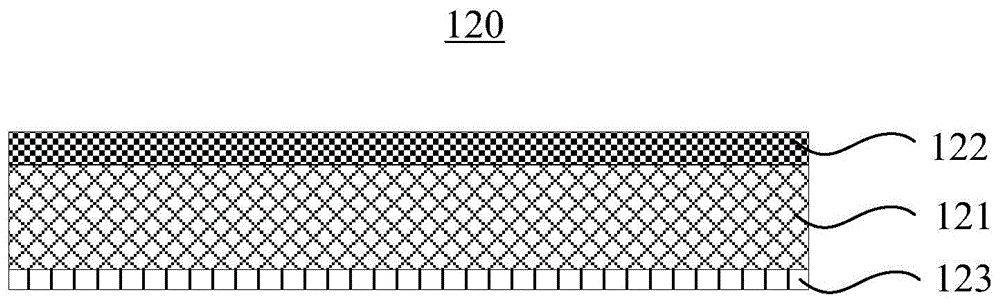

[0015] Such as figure 1 As shown, the touch screen provided by an embodiment of the present invention includes a protective cover 100 , a capacitive sensing structure 120 , and a transparent optical adhesive layer 110 bonding the protective cover 100 and the capacitive sensing structure 120 .

[0016] The protective cover 100 may be a glass cover or an organic plastic cover, such as PMMA, PC, etc., preferably a glass cover. Further, an antiglare layer (not shown) is formed on at least one surface of the protective cover. For example, when the protective cover 100 is a glass cover, it can be made through a special chemical process (such as etching the glass cover with a chemical solution of hydrofluoric acid), so that the reflective surface of the glass can be changed into a matte diffuse reflection surface. . This can not only prevent glare, but also reduce the reflectivity and reduce light and shadow. In addition, the anti-corrosion and anti-scratch properties of the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com