Medium-voltage electrical penetrating member ceramic component

An electrical penetration, medium-voltage technology, applied in nuclear power generation, greenhouse gas reduction, climate sustainability, etc., can solve the problems of poor radiation resistance, corrosion and high temperature and high pressure capability, short service life, and poor structural strength, etc. To achieve the effect of strong insulation performance and pressure bearing capacity, good seismic buffering effect and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

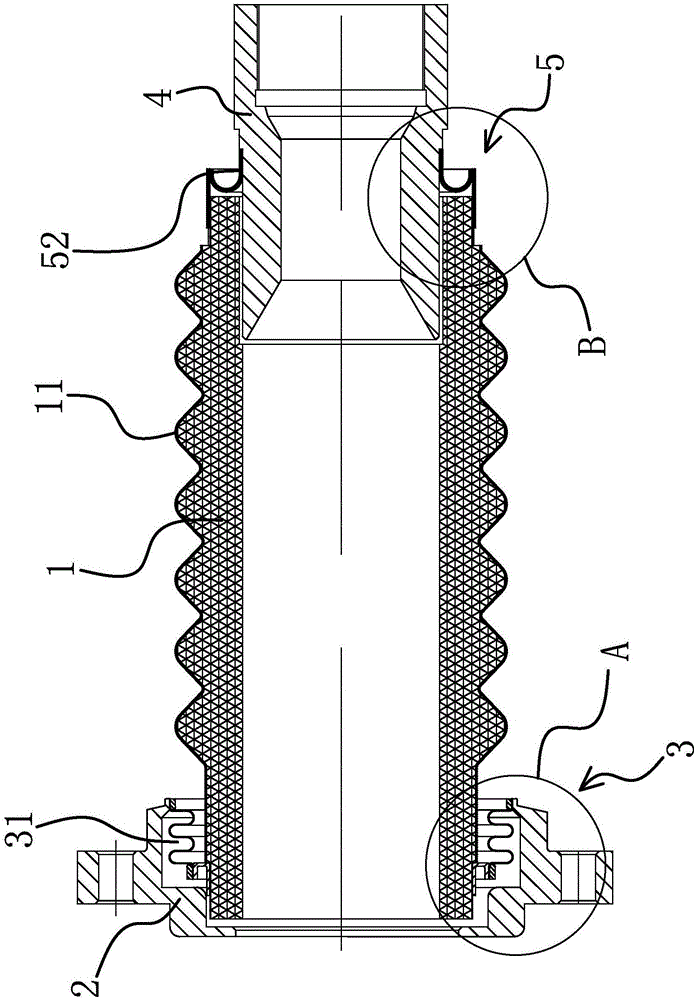

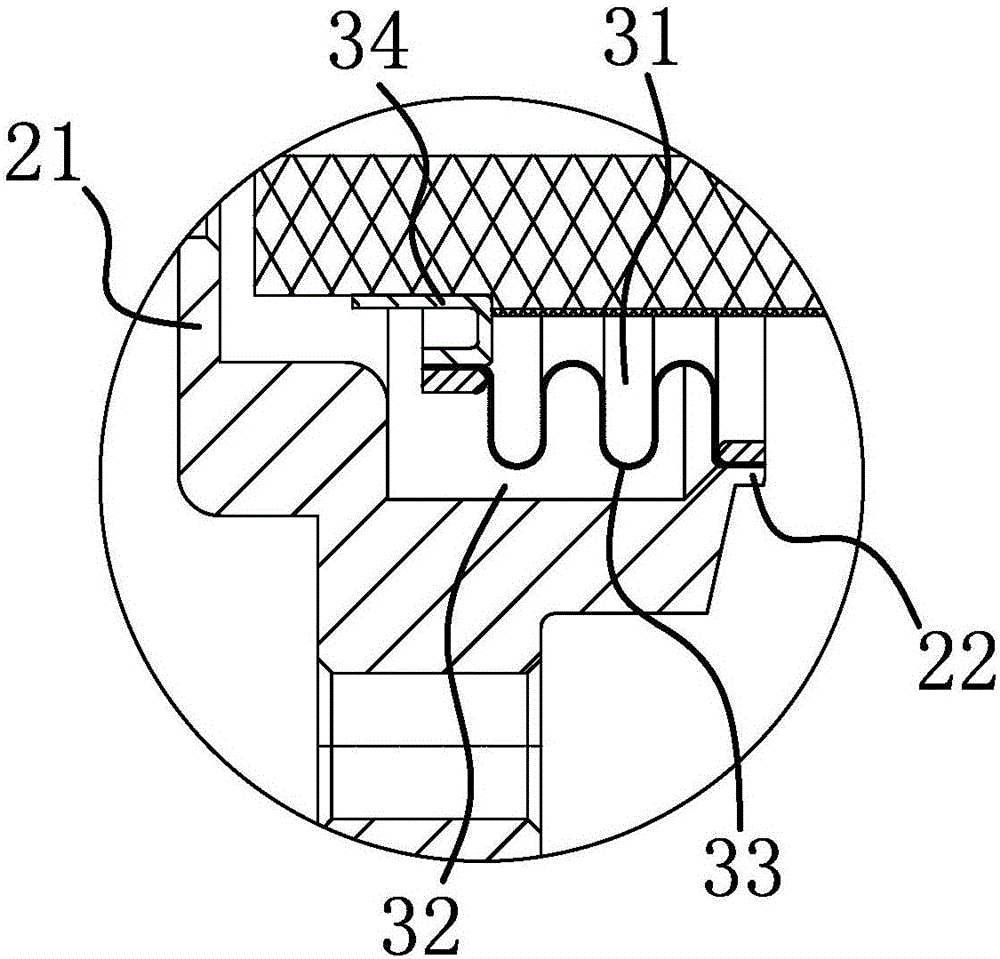

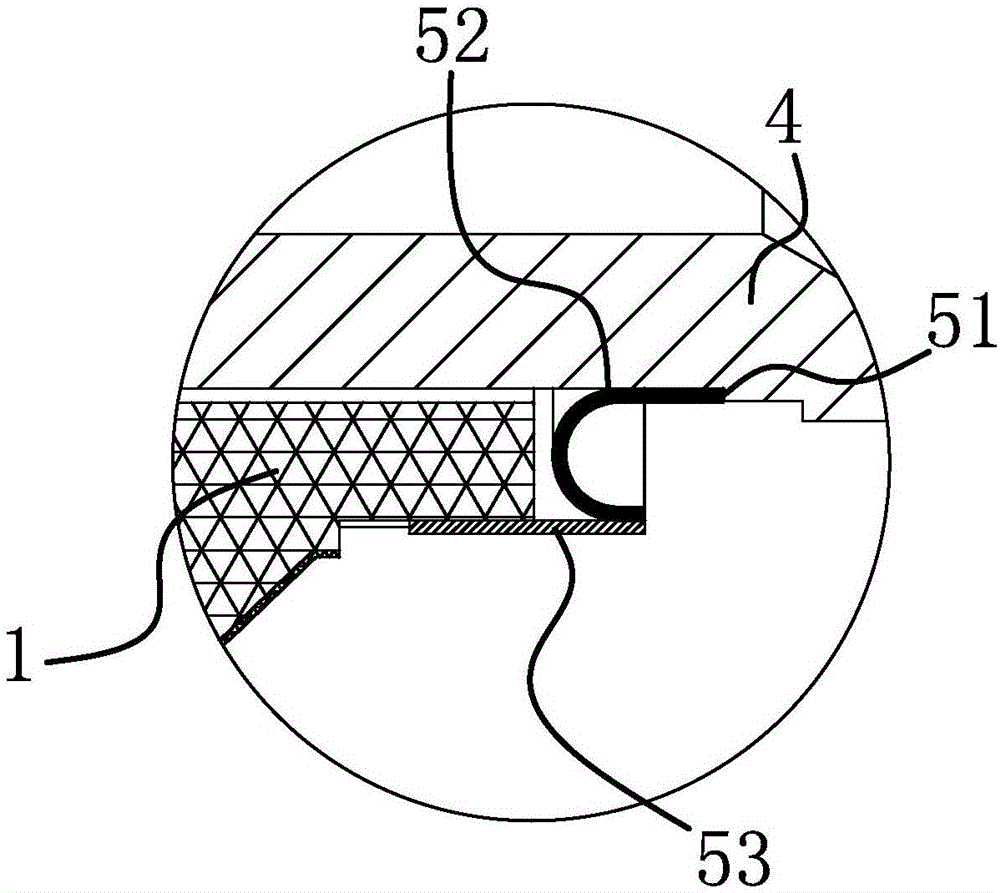

[0021] Such as Figure 1-3 As shown, the ceramic assembly of the medium-voltage electrical penetration part includes a cylindrical medium-voltage magnetic part 1, one end of the medium-voltage magnetic part 1 is provided with a magnetic part flange 2, and the circumferential inner side of the magnetic part flange 2 is connected to the medium-voltage magnetic part. There is a buffer connection structure 3 between the outer side of the magnetic part 1 and the flange 2 of the magnetic part and the medium voltage magnetic part 1. The other end of the medium voltage magnetic part 1 is inserted with a magnetic part holder 4, and the magnetic part is clamped The seat 4 is fixedly arranged at the end of the medium-voltage magnetic part 1 through the positioning structure 5, that is, the buffer connection structure 3 makes the magnetic part fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com