Method for simultaneously fabricating semiconductor elements in unit cell region and surrounding region

A technology of unit cell area and surrounding area, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as damage to extremely thin oxide layers, and achieve the effect of reducing the risk of oxide layer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

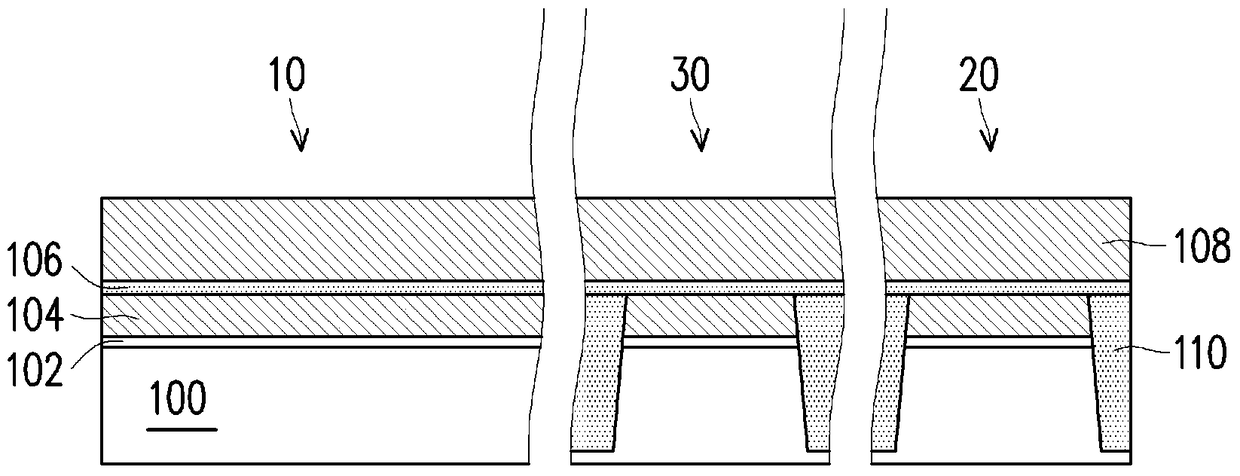

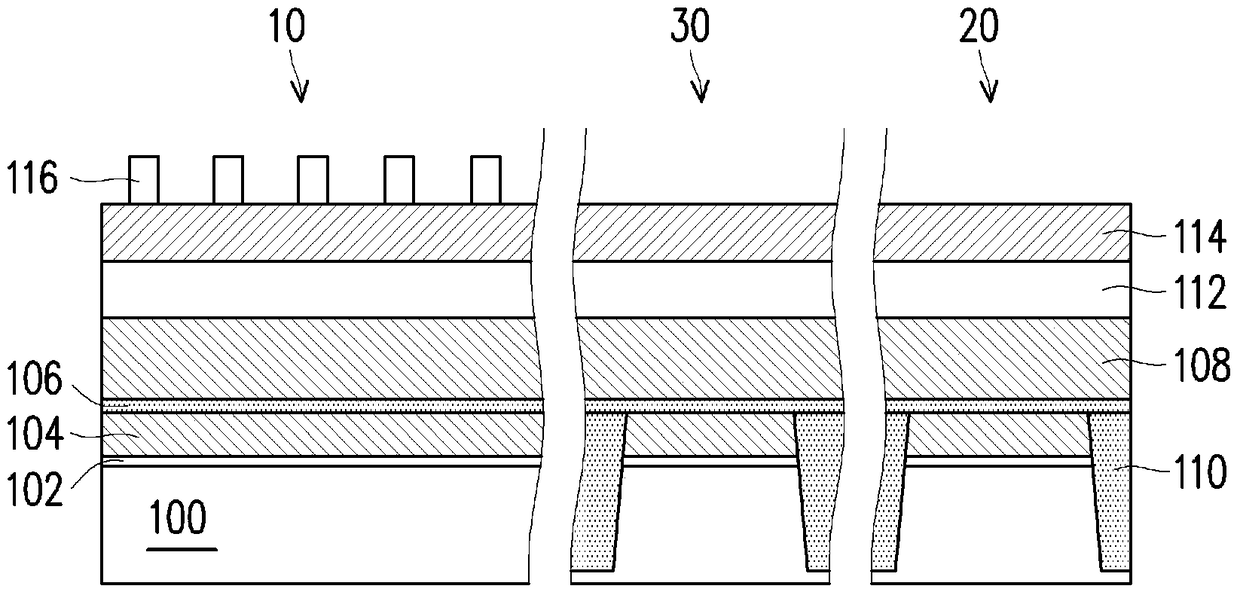

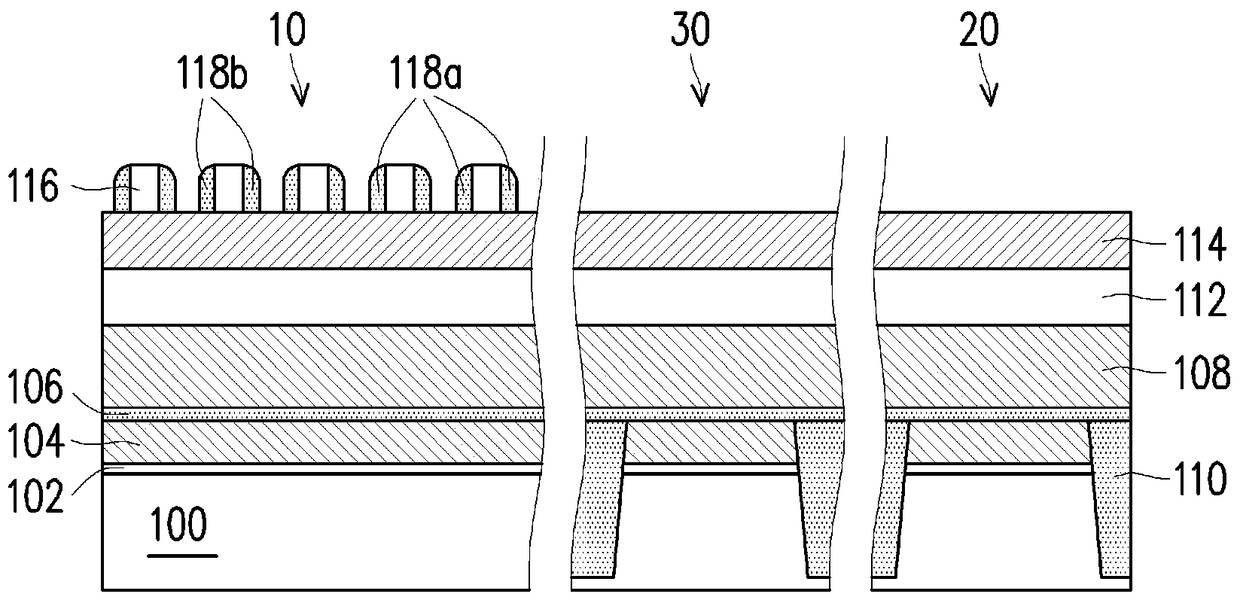

[0050] Figure 1A to Figure 1H It is a schematic cross-sectional view of a manufacturing process of a semiconductor device in which a unit cell region and a surrounding region are simultaneously manufactured according to the first embodiment of the present invention.

[0051] Please refer to Figure 1A , a substrate 100 is provided, and the substrate 100 has a unit cell area 10 and a surrounding area 20 . There is also a capacitor region 30 in the substrate 100 of the present embodiment. Although there is only one unit cell region 10 , surrounding region 20 and capacitor region 30 in the figure, the present invention is not limited thereto. Then, a gate oxide layer 102 , a first conductive structure layer 104 , an inter-gate dielectric layer 106 and a second conductive structure layer 108 are sequentially formed on the substrate 100 . The first conductive structure layer 104 is, for example, a single-layer or double-layer structure made of tungsten, aluminum, copper, polysil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com