Method for neutral beam processing based on gas cluster ion beam technology and articles produced thereby

A technology of gas clusters and ions, applied in ion implantation plating, sputtering plating, electrical components, etc., can solve problems such as etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

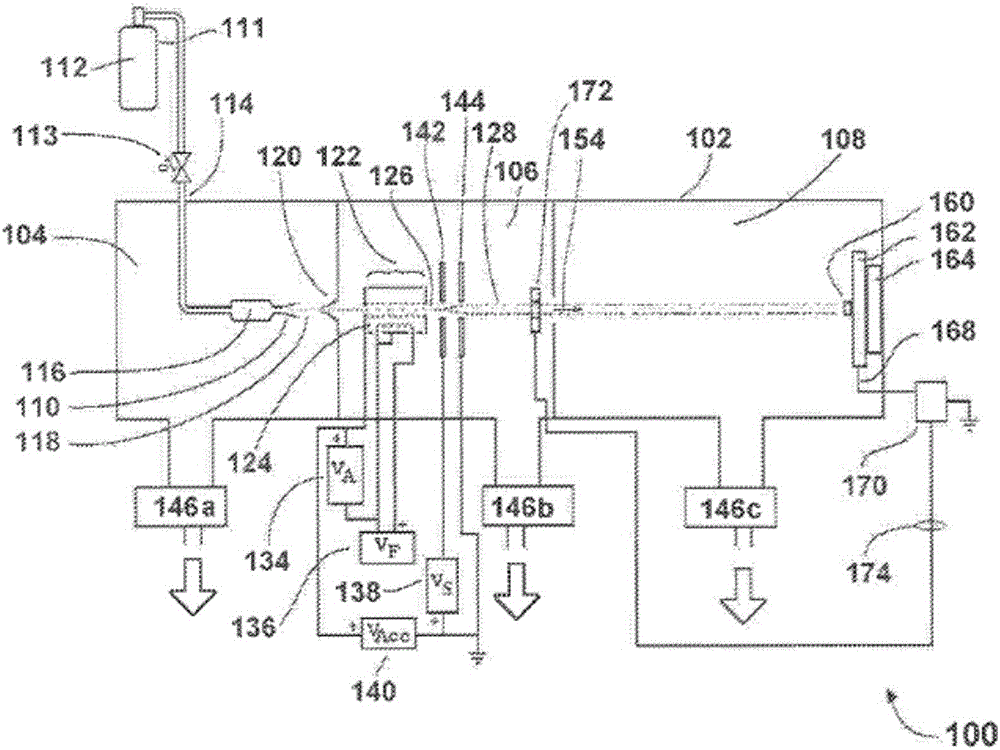

[0090]Referring now to FIG. 1 , FIG. 1 shows a schematic structure of a GCIB processing device 100 in the prior art. The low pressure vessel 102 has three fluidly connected chambers: a nozzle chamber 104 , an ionization / acceleration chamber 106 and a process chamber 108 . The three chambers are evacuated by vacuum pumps 146a, 146b and 146c, respectively. Pressurized condensable source gas 112 , such as argon, stored in gas storage cylinder 111 flows through gas metering valve 113 and feed tube 114 into stagnation chamber 116 . The pressure (typically several atmospheres) in the stagnation chamber 116 causes gas to be ejected through the nozzle 110 into a substantially lower pressure vacuum, resulting in the formation of a supersonic gas jet 118 . The cooling caused by the expansion in the jet causes a portion of the gas jet 118 to condense into clusters, each cluster consisting of a few to thousands of weakly bound atoms or molecules. The gas filter 120 controls the flow of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com