Aqueous rubber asphalt waterproof sealing glue

A rubber asphalt and waterproof sealing technology, which is applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve problems such as inability to meet construction needs, expensive materials, and low performance indicators, and achieve long-term development plans and improve Economic benefits, far-reaching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

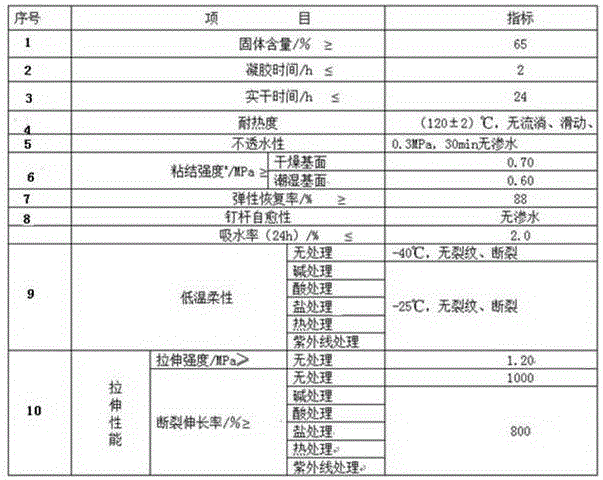

Image

Examples

Embodiment 1

[0018] A water-based rubber asphalt waterproof sealant, comprising the following raw materials in parts by weight: 745 parts of emulsified asphalt, 10 parts of chloroprene rubber, 15 parts of styrene-butadiene rubber, 15 parts of coumarone resin, 5 parts of insoluble sulfur, and expanded vermiculite 1 part, 6 parts of dispersant, 3 parts of defoamer, 2 parts of water, 1 part of accelerator, 1 part of wetting agent, 5 parts of flame retardant, dispersant is dispersant 5040, defoamer is defoamer 191 , the tin accelerator is dibutyltin dilaurate, the wetting agent is polyoxyethylene alkylphenol ether and polyoxyethylene fatty alcohol ether, and the mass ratio of polyoxyethylene alkylphenol ether and polyoxyethylene fatty alcohol ether is 1:2, the flame retardant is decabromodiphenylethane, octabromoether and decabromodiphenylethane, the flame retardant is the mass ratio of decabromodiphenylethane, octabromoether and decabromodiphenylethane 2:5:3, the preparation steps are as foll...

Embodiment 2

[0020] A water-based rubber asphalt waterproof sealant, comprising the following raw materials in parts by weight: 85 parts of emulsified asphalt, 15 parts of chloroprene rubber, 26 parts of styrene-butadiene rubber, 20 parts of coumarone resin, 10 parts of insoluble sulfur, and expanded vermiculite 5 parts, 8 parts of dispersant, 5 parts of defoamer, 2-8 parts of water, 5 parts of accelerator, 3 parts of wetting agent, 10 parts of flame retardant, dispersant is Dispersant 5040, defoamer is defoamer Agent 191, the tin accelerator is dibutyltin dilaurate, stannous octoate and CT-E229, the mass ratio of dibutyltin dilaurate, stannous octoate and CT-E229 is 2:3:5, and the wetting agent is Polyoxyethylene alkylphenol ether, the flame retardants are decabromodiphenylethane, octabromoether and decabromodiphenylethane, the flame retardants are decabromodiphenylethane, octabromoether and decabromodiphenyl The mass ratio of ethane is 2:5:3, and the preparation steps are as follows, wit...

Embodiment 3

[0022] Water-based rubber asphalt waterproof sealant, including the following raw materials in parts by weight: 80 parts of emulsified asphalt, 13 parts of chloroprene rubber, 20 parts of styrene-butadiene rubber, 17 parts of coumarone resin, 8 parts of insoluble sulfur, and 3 parts of expanded vermiculite , 7 parts of dispersant, 4 parts of defoamer, 5 parts of water, 3 parts of accelerator, 2 parts of wetting agent, 8 parts of flame retardant, dispersant is dispersant 5040, defoamer is defoamer 191, tin The accelerator is dibutyltin dilaurate, stannous octoate and CT-E229, the mass ratio of dibutyltin dilaurate, stannous octoate and CT-E229 is 1:3:1, and the wetting agent is polyoxyethylene alkanes Base phenol ether and polyoxyethylene fatty alcohol ether, the mass ratio of the two is 5:3, the flame retardant is decabromodiphenylethane, octabromoether and decabromodiphenylethane, and the flame retardant is decabromodiphenylethane The mass ratio of ethyl phenylene, octabromoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com