A method for detecting the migration of flavor components in the gas phase of mainstream smoke of flavored cigarettes

A technology for mainstream cigarette smoke and mainstream smoke, which is applied in material separation, measuring devices, analyzing materials, etc., can solve the problems of not establishing standard methods, affecting the accuracy of analysis, and many interfering substances, so as to overcome the complexity of detection components, To control the quality of flavored cigarettes and adjust the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Sample processing and instrument detection steps are as follows:

[0054] 1. Smoke the sampled cigarettes according to the ISO standard smoking conditions, smoke 4 cigarettes for each experiment, and the length of the cigarette butt is 33cm. A Ф44mm Cambridge filter was used to capture the particulate matter of mainstream cigarette smoke, and a Carbotrap349 thermal desorption sampling tube was connected in series behind the trap to capture the gas phase matter of mainstream cigarette smoke.

[0055] 2. Select D3-phenethyl acetate as the internal standard solution, the concentration is 0.02g / mL, and the solvent is dichloromethane. Add 3 μL of internal standard solution to each thermal desorption sampling tube, and then use ATD-GC / MS to inject and analyze.

[0056] 3. See Table 1 and Table 2 for the analysis and detection conditions of thermal desorption (ATD) instruments and gas chromatography-mass spectrometry (GC / MS) instruments.

[0057] Table 1 Thermal desorption c...

Embodiment 2

[0082] Taking the flavoring material A as an example, the analysis method of the transfer behavior of the flavoring material in the gas phase of mainstream cigarette smoke is introduced.

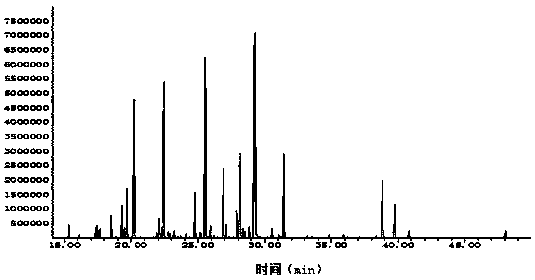

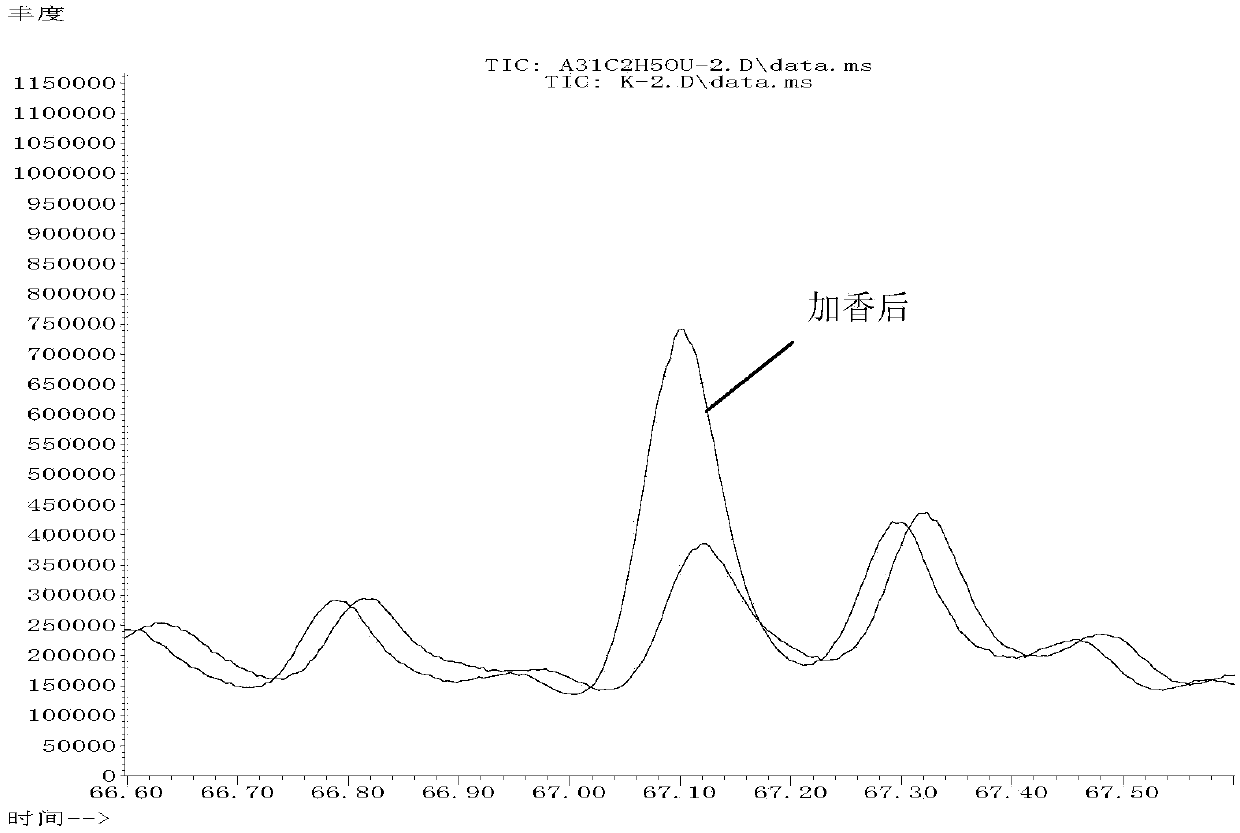

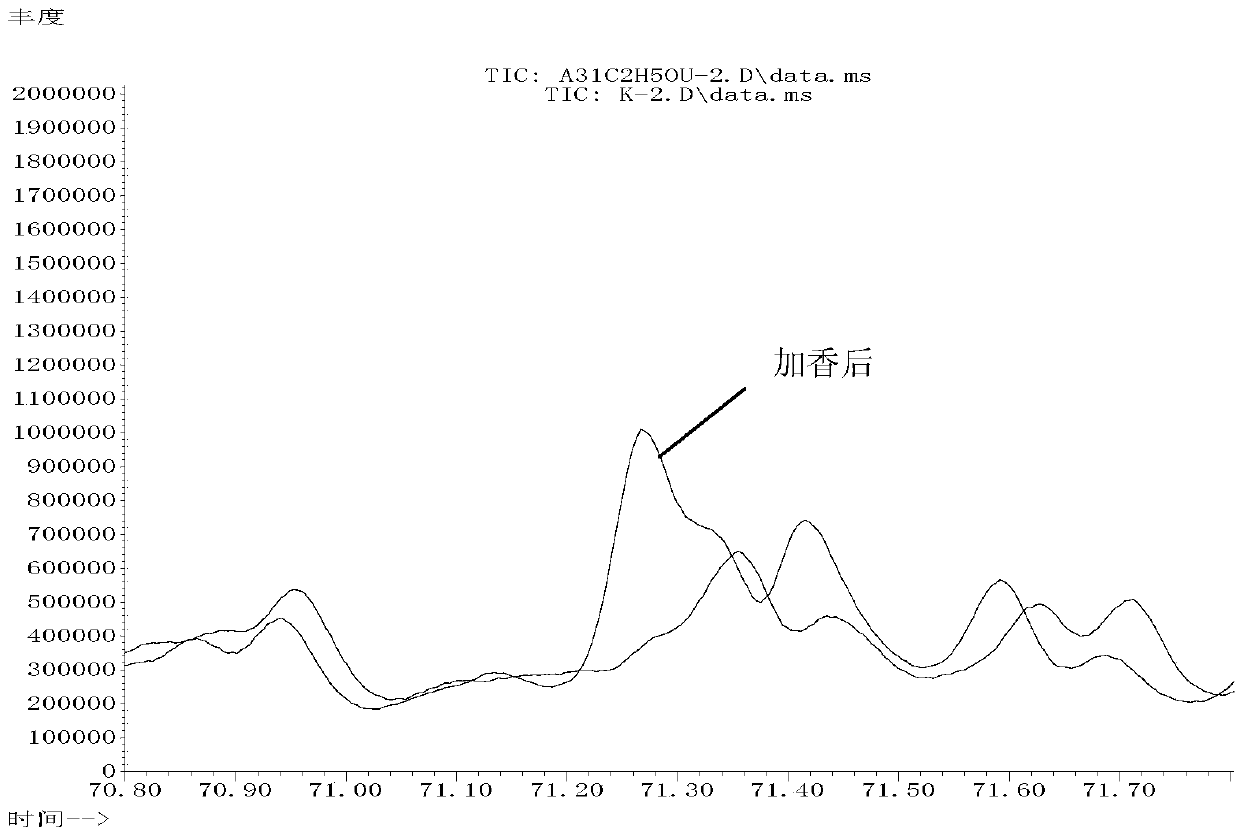

[0083] 1. Analysis of gas phase components of cigarette mainstream smoke before and after the addition of flavoring material A. For the composition analysis of flavoring material A, see figure 1 .

[0084] The composition analysis method of fragrance raw material A is as follows: take 10 μL of fragrance raw material A, dissolve it in ethanol / dichloromethane / dimethylformamide in an appropriate proportion, and perform detection according to the GC / MS conditions in Table 5. (A suitable solvent can be selected according to the dissolution situation. When the main component concentration in the analyte is low, the sampling amount of the fragrance raw material can be appropriately increased.), and its components are qualitatively analyzed with the NIST library and the AMDIS library, as listed in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com