Heat storage device of travelling wave tube

A storage device and traveling wave tube technology, which are applied to discharge tubes, transit time electron tubes, collectors of transit time electron tubes, etc. Line fuse and other problems, to achieve good sealing effect, prevent leakage, and increase the effect of loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

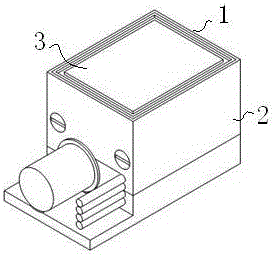

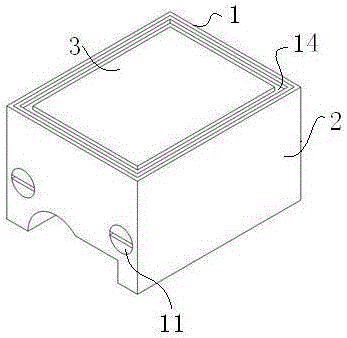

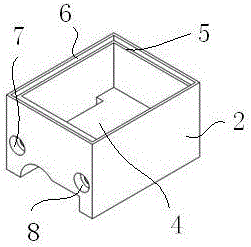

[0019] A traveling wave tube heat storage device in an embodiment of the present invention, the traveling wave tube heat storage device includes a phase change material (a phase change material with a phase change temperature of 65°C), a base and a cover plate; The base and the cover plate are made of aluminum; the base is provided with a storage cavity for accommodating phase change materials, an assembly upper end surface arranged on the top of the storage cavity, and a base arranged around the inner wall of the top of the storage cavity to be welded. Wall, injection hole, sealing hole, assembly lower end surface in contact with the bottom plate of the traveling wave tube, heat dissipation surface placed at the bottom of the base and closely fitted with the collecting pole of the traveling wave tube, sealing screws for sealing the injection hole and sealing hole; The cover plate includes a bottom surface of the cover plate in contact with the assembly upper end surface, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com