Polyolefin microporous film, separator for non-aqueous electrolyte secondary battery, wound product of polyolefin microporous film, non-aqueous electrolyte secondary battery, and method for producing polyolefin microporous film

A non-aqueous electrolyte, microporous membrane technology, applied in the field of polyolefin-made microporous membranes, can solve the problem of not being able to have both high strength and high permeability, and achieve excellent appearance, puncture strength and excellent air resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] (a) Preparation of polyolefin solution

[0054] A polyolefin solution obtained by heating and dissolving a polyolefin resin in a plasticizer is prepared. The plasticizer is not particularly limited as long as it is a solvent capable of sufficiently dissolving polyethylene. In order to enable stretching at a higher ratio, the solvent is preferably liquid at room temperature. Examples of liquid solvents include aliphatic, cycloaliphatic or aromatic hydrocarbons such as nonane, decane, decalin, p-xylene, undecane, dodecane, liquid paraffin, and mineral oils with corresponding boiling points. Fractions, and phthalates that are liquid at room temperature, such as dibutyl phthalate and dioctyl phthalate. In order to obtain a gel-like sheet with a stable liquid solvent content, it is preferable to use a non-volatile liquid solvent such as liquid paraffin. In the melt-kneading state, a solvent that is mixed with polyethylene but is solid at room temperature may be mixed with...

Embodiment 1

[0151]

[0152] For the weight average molecular weight (Mw) of 2.5×10 6 Ultra-high molecular weight polyethylene (UHMWPE) 40% by mass and Mw is 2.8×10 5 100 parts by mass of a polyethylene (PE) composition composed of 60 mass percent of high-density polyethylene (HDPE), dry-mixed tetrakis [methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl) - 0.375 parts by mass of propionate] methane to obtain a mixture.

[0153] 25 parts by mass of the obtained mixture were put into a strong mixing type twin-screw extruder (the input amount Q of the polyethylene composition: 54kg / h), and 75 g of flowing paraffin was supplied from the side feeder of the twin-screw extruder. Parts by mass were melt-kneaded at a temperature of 210° C. (Q / Ns: 0.3 kg / h / rpm) while maintaining the screw speed Ns at 180 rpm to prepare a polyethylene solution.

[0154] The obtained polyethylene solution was supplied to a T-die from a twin-screw extruder, and extruded into a sheet-shaped molded body. The extruded mo...

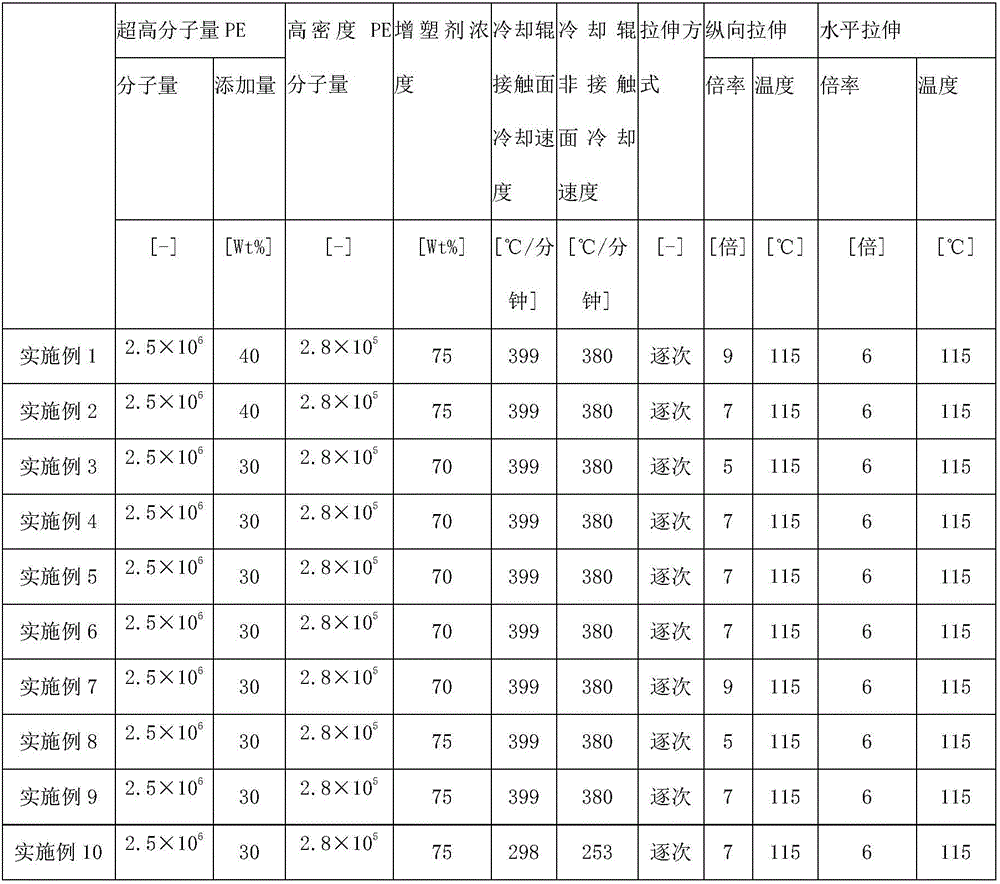

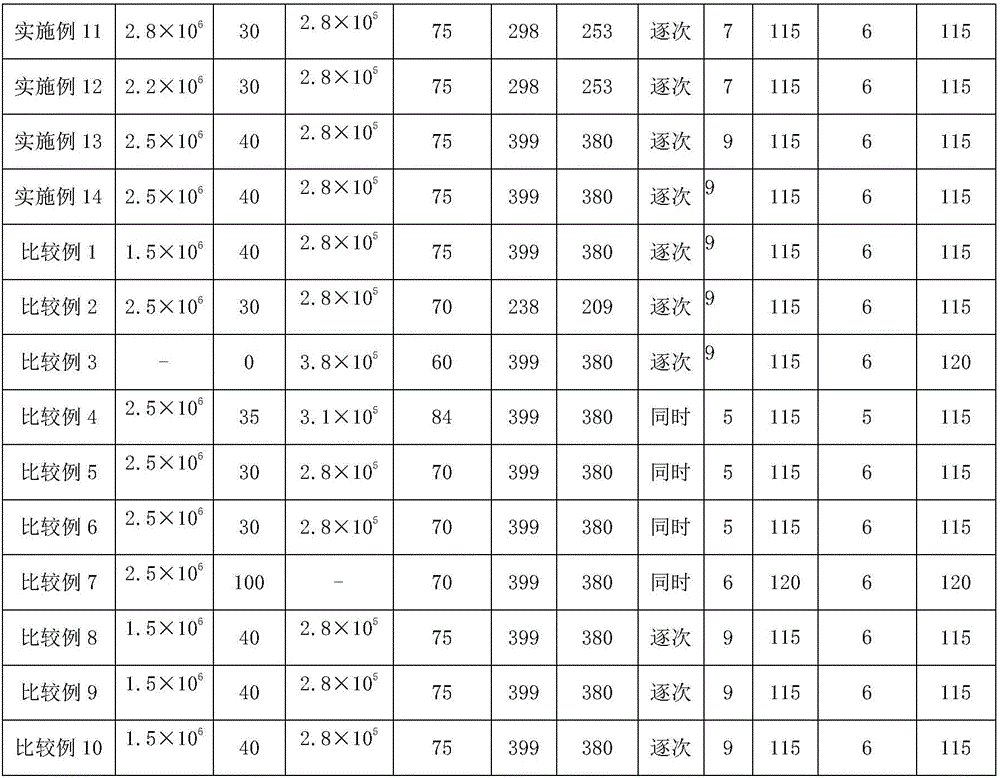

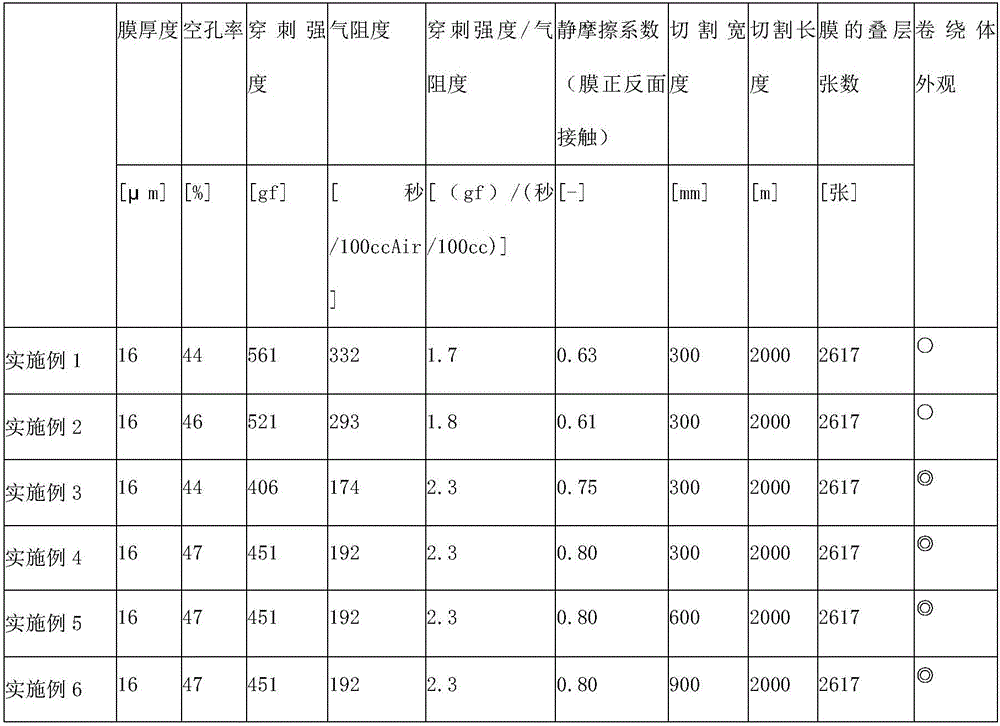

Embodiment 2~14、 comparative example 1、2、8~10

[0156] Except that the Mw of the UHMWPE used, the resin composition, the film forming conditions, the cutting width, the length, and the number of laminated sheets of the film wound on the core were changed as shown in Tables 1 and 2, the same as in Example 1 In the same manner, a polyolefin microporous membrane roll was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com