Ecological energy-saving building wall system

A building wall and ecological technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of reducing the indoor use area, the heat insulation layer is easily damaged, and is not as good as the external heat preservation, so as to achieve the optimization of energy utilization, Mitigate the heat island effect and increase the effect of natural color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

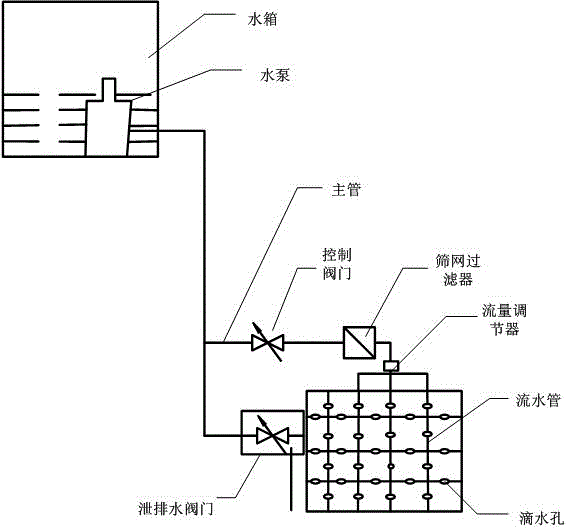

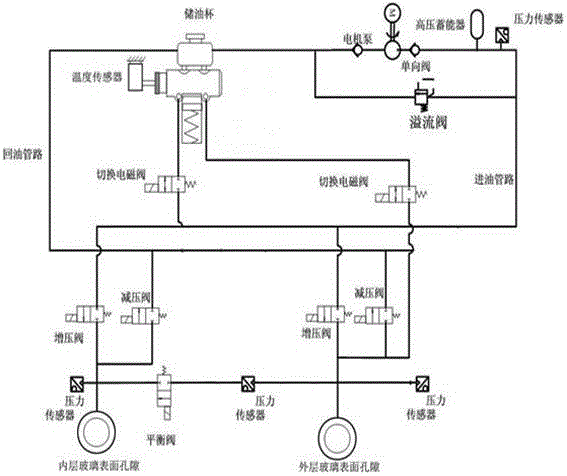

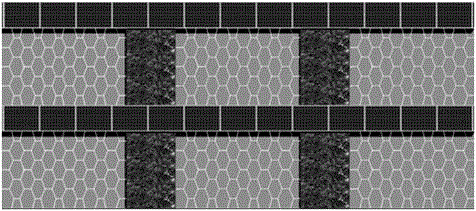

[0026] An ecological energy-saving building wall system includes a horizontal solar panel system and a vertical greening system. The vertical greening system includes a support system, a greening irrigation system, a cultivation medium system and a plant material system. And the glass surface pore automatic control system located between the two. The glass surface pore automatic control system is powered by a horizontal solar panel system, and uses electro-hydraulic technology and building automation systems to control the size of the glass surface pores. The electro-hydraulic control system includes an oil pump, a relief valve, an accumulator filling valve, an accumulator, and a pressure-sensing regulating valve, and the building automation system includes a temperature sensor, an induction device with an electronic sensor, and an electronic control unit and electro-hydraulic adjustable brake valves. Working principle: The temperature sensor converts the temperature change in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com