Remote bilateral balancing composite driver soft transmission system for agricultural greenhouse sunshading and heat preserving

A sunshade heat preservation and transmission system technology, applied in agriculture, greenhouse cultivation, application, etc., can solve the problems of waste of resources, artificial increase, and difficulty in using agricultural machinery, and achieve the effect of reducing usage and high level of automation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

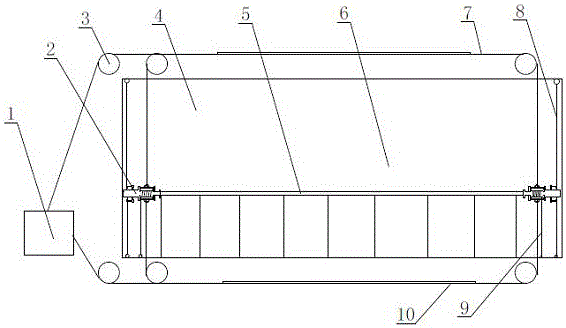

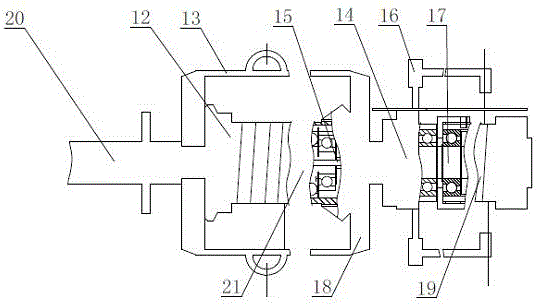

[0017] Such as figure 1 and figure 2 A long-distance double-balanced composite driver soft transmission system for sunshade and heat preservation of agricultural greenhouses, including power assembly 1, guide wheel 3, greenhouse skeleton net bed 4, roll quilt shaft 5, heat preservation quilt 6, upper traction rope 7 and lower The traction rope 10, the power assembly 1 is respectively connected with the remote balance compound driver 2 through the guide wheel 3, the upper traction rope 7 and the lower traction rope 10; the heat preservation quilt 6 is rolled on the quilt shaft 5; The shaft 5 is connected; one end of the auxiliary driving rope 8 is fixed on the top of the greenhouse, and the other end is fixed on the bottom of the greenhouse, and the auxiliary driving rope 8 is wound around the auxiliary driving drum 19 of the remote balancing composite driver 2; one end of the main driving rope 9 is connected to the remote balancing composite driver The main driving drum 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com