Huangshan local oolong making method

A production method and technology of oolong tea, applied in tea treatment before extraction, climate change adaptation, etc., can solve the problems of high human resource consumption, difficulty in improving processing efficiency, complicated process, etc., to improve quality and taste, ensure processing quality, Effect of reducing bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

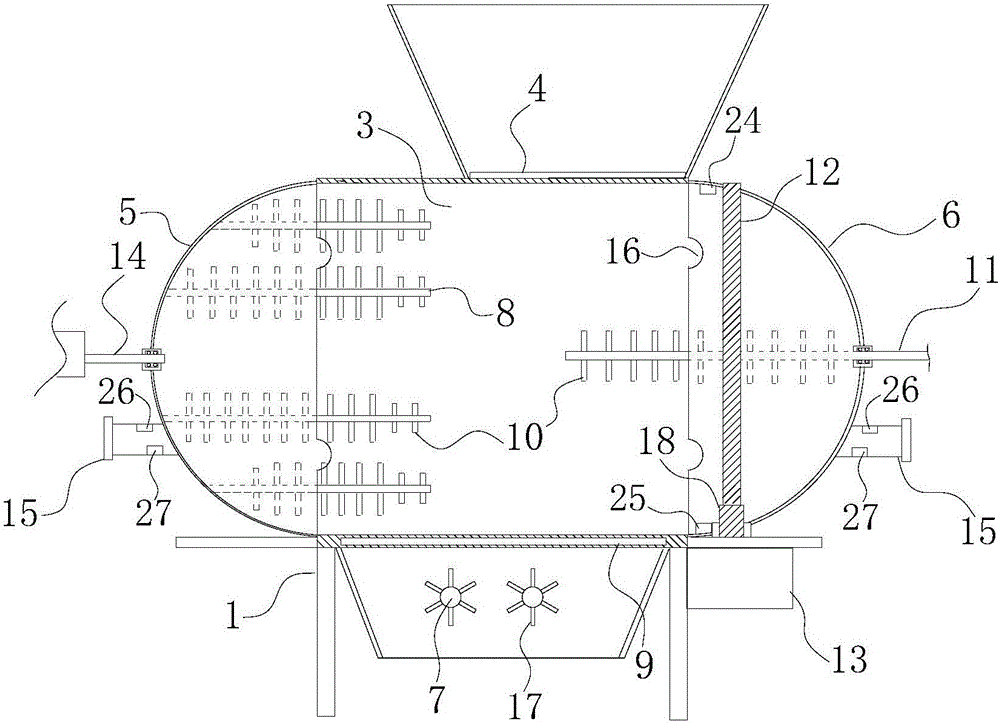

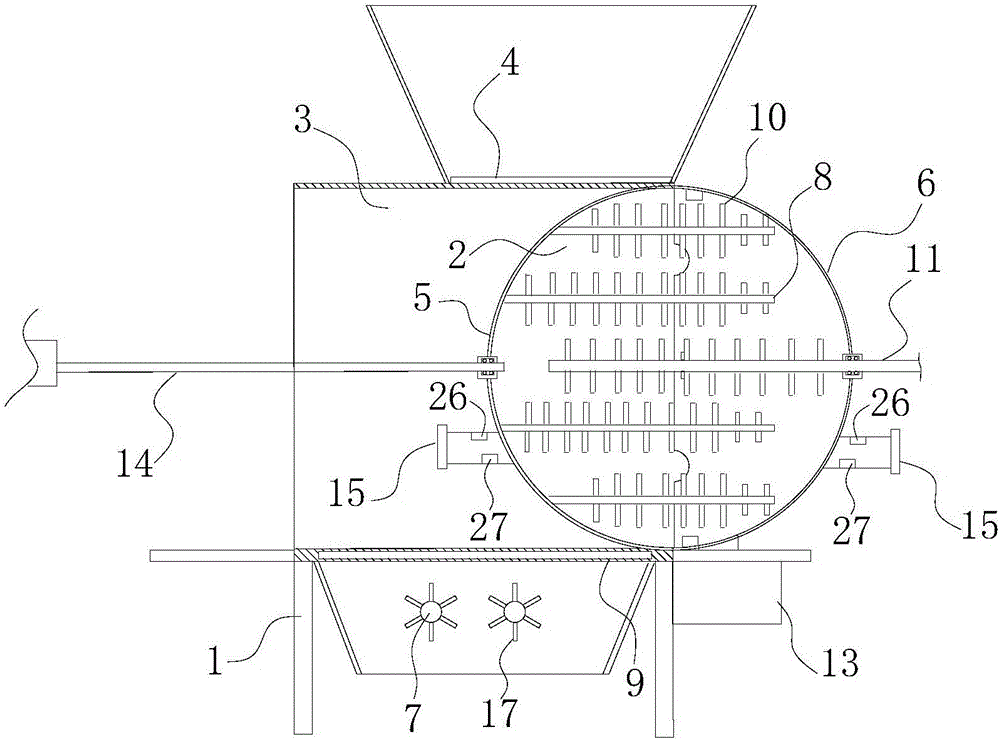

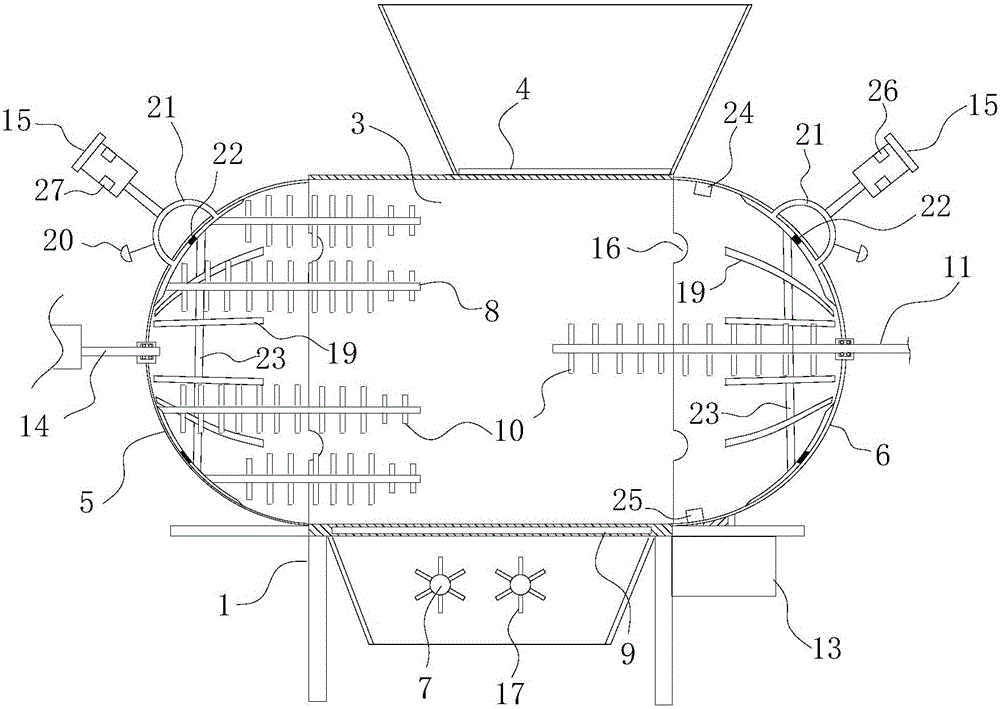

Image

Examples

Embodiment 1

[0038] Select fresh leaves with 2 to 3 leaves on the local tea trees in Huangshan for picking, and spread the leaves in the sun according to the amount of 0.6kg / m 2 Spread the fresh leaves and dry them until the weight loss rate of the tea leaves is 5%, then move the tea leaves indoors to dry for 40 minutes. Use the green shaker to shake the blue and green and let it stand to dry. The first shake is set at a speed of 10r / min, which lasts 3min, and the green is dried for 1h after shaking; the second shake is set at a speed of 15r / min, which lasts 5min. Dry the green leaves for 1 hour; set the rotation speed of 20r / min for the third time, and last for 10 minutes. After shaking the green leaves, dry the green leaves for 7 hours. When drying the green leaves, the thickness of the leaves is 2cm. It is advisable to shake out the fragrance of the tea leaves and air out the green leaves and red borders.

[0039] Utilize the drum stir-fry machine, stir-fry green leaves at a temperature...

Embodiment 2

[0043] Select fresh leaves with 2 to 3 leaves on the local tea trees in Huangshan for picking, and spread the leaves in the sun according to the amount of 0.7kg / m 2 Spread fresh leaves and dry until the weight loss rate of the tea leaves is 5%, then move the tea leaves indoors to dry for 45 minutes. Use the green shaker to shake the blue and green and let it stand to dry. The first shake is set at a speed of 11r / min, which lasts 2min, and after shaking the green is dried for 1.5h; the second shake is set at a speed of 16r / min, which lasts 5min. After airing blue and green 1.5h; The third airing blue and green setting speed 20r / min, lasted 12min, shake green and blue and then air blue and blue 8h, spread leaf thickness 2.5cm when airing blue and green. Using a roller frying machine, stir-fry green leaves at a temperature of 280°C until the leaf weight loss rate is 30%. Spread the fried green leaves to dissipate the water vapor in them, then quickly rub the tea leaves and sieve ...

Embodiment 3

[0047] Select the fresh leaves with 2-3 leaves on the local tea tree in Huangshan for picking, and spread the leaves in the sun according to the amount of 0.8kg / m 2 Spread the fresh leaves and dry them until the weight loss rate of the tea leaves is 4%, then move the tea leaves indoors to dry for 50 minutes. Use the green shaker to shake the blue and green and let it stand to dry. The first shake is set at a speed of 10r / min, which lasts 3min, and then aired for 2h after shaking; the second shake is set at a speed of 14r / min, which lasts 6min. Dry blue and green for 2 hours; set the rotation speed of 19r / min for the third time, and last for 9 minutes, shake blue and green leaves for 9 hours, and spread the leaf thickness of 3cm when drying blue and green leaves. Using a roller frying machine, stir-fry green leaves at a temperature of 290°C until the leaf weight loss rate is 32%, spread out the fried green leaves to dissipate the water vapor, and then quickly rub the tea leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com