Exhaust gas purification system

An exhaust gas purification system and exhaust gas technology, applied in incinerators, chemical instruments and methods, separation methods, etc., can solve problems such as uneven mixing, insufficient combustion of harmful gases, etc., to overcome uneven mixing, improve adequacy, The effect of high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

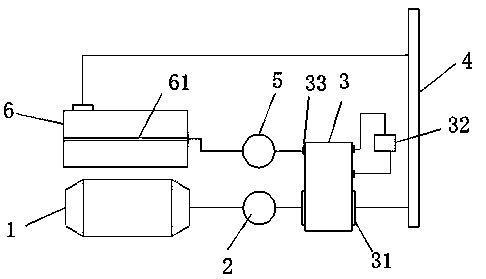

[0021] Such as figure 1 As shown, the exhaust gas purification system is mainly used for the filtration and treatment of VOC gas, which includes a pre-filter 1, which is used to remove solid particles and moisture in the gas, and the pre-filter 1 is connected with a molecular sieve runner 3. The molecular sieve wheel includes a treatment area, a cooling area and a regeneration area. Driven by the motor, the molecular sieve wheel rotates at a speed of 1-6 revolutions per hour, and the gas containing organic solvents flows through the treatment area and becomes relatively clean. The air whose organic solvent content reaches the national environmental protection emission requirements, the first outlet 31 of the molecular sieve runner 3 is connected with the exhaust device 4, and the exhaust device is to discharge clean gas into a high-altitude chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com