Absorbent, and preparation method and mercury removal method thereof

An absorbent and removal technology, which is applied in the field of boilers, can solve the problems of difficult recovery, poor apparent magnetic properties of catalysts, and large dosage, so as to achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Weigh 30.7g of potassium hydrogen persulfate, dissolve it in 100L water, stir, mix well, and use 0.1mol / L Na 2 CO 3 -NaHCO 3 Adjust the pH value of the buffer solution to 8, and then add 8.297 g of cobalt ferrite as a catalyst. At this time, the weight ratio of potassium monopersulfate to the catalyst is 3.7:1, and the absorbent can be obtained by stirring. When the concentration of elemental mercury in flue gas is 100 μg / m 3 When the reaction temperature is 55 ° C; the reaction pH is 8, in the bubble reactor, the gas-liquid contact time is 0.5 seconds, and the elements in the flue gas are measured by the QM201H coal-fired flue gas mercury detector (Suzhou Qingan Instrument Co., Ltd.) The removal rate of mercury can reach 85%.

Embodiment 2

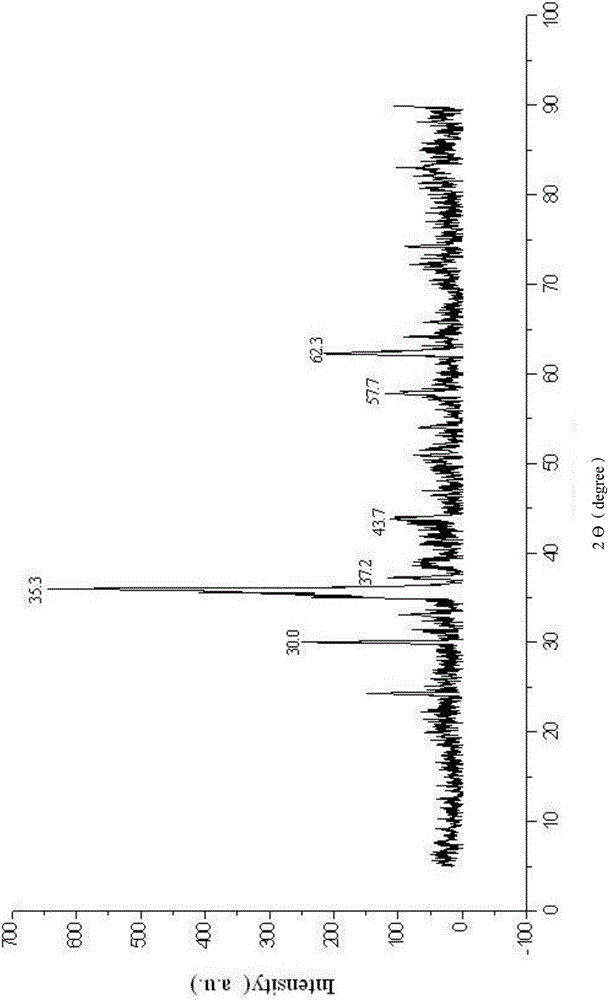

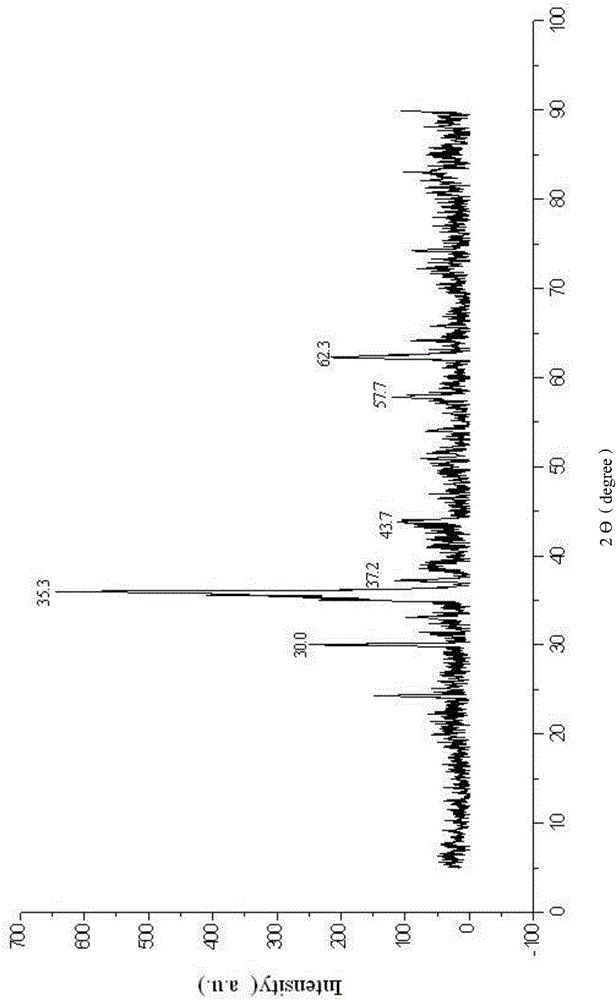

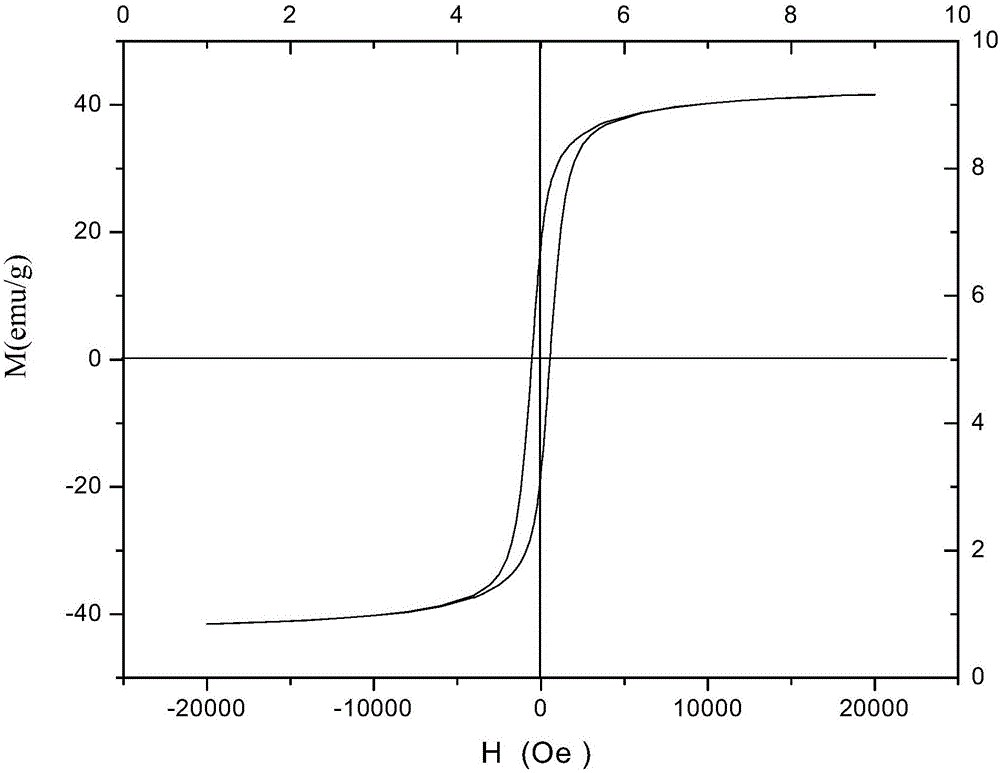

[0059] 1) Weigh 0.188g of graphite oxide and add it into 70mL of water, and ultrasonicate for 2.5 hours to form a uniformly dispersed suspension; 0.3493g of Co(NO 3 ) 2 ·6H 2 O and 0.9696gFe(NO 3 ) 3 9H 2 Dissolve O in 10mL deionized water to form a yellow solution and mix it with the suspension containing graphite oxide. Stir magnetically for 30 minutes to mix the two substances evenly. Use NaOH (6mol / L) to adjust the pH of the solution to greater than 12 and continue magnetic stirring. After 30 minutes, it was transferred to a 100mL hydrothermal reaction kettle and placed in an oven at 200°C for 12 hours. Cool to room temperature after the end, centrifuge and wash several times, and repeatedly wash with absolute ethanol to remove impurities therein, and finally dry in a vacuum oven at 60°C to obtain a 40% graphite-loaded cobalt ferrite catalyst (referred to as CoFe 2 o 4 -GO (0.4)), the graphite-supported ene cobalt ferrite catalyst obtained by measuring carries out X ...

Embodiment 3

[0062] 1) Prepare a graphite-supported cobaltene ferrite catalyst with a loading of 10% in the same manner as in Example 2, and adjust the proportion of the used substances according to the finally obtained loading.

[0063] 2) Weigh 60g of potassium hydrogen persulfate, dissolve it in 100L of water, stir, mix well, and use 0.1mol / L Na 2 CO 3 -NaHCO 3 The buffer solution adjusts the pH value to 5.5, and then adds 60 g of the graphene-loaded cobalt ferrite catalyst prepared in step 1) (the load is 10%). At this time, the weight ratio of potassium monopersulfate to the catalyst is 1:1, and stirring can obtain absorbent. When the concentration of elemental mercury in flue gas is 10 μg / m 3 When the reaction temperature is 25°C; the reaction pH is 5.5, in the bubble reactor, the gas-liquid contact time is 0.5 seconds, and the removal rate of elemental mercury in the flue gas measured by the QM201H coal-fired flue gas fluorescence mercury detector reaches 80 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com