A kind of preparation method of heat-insulating sound-insulating shock-absorbing fiber felt

A technology of heat insulation and sound insulation and fiber felt, which is applied in the field of preparation of heat insulation, sound insulation and shock absorbing fiber felt, which can solve the problems of environmental pollution, harmful substances, and human injury in the car, so as to ensure the connection quality, outstanding sound insulation effect, reduce effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

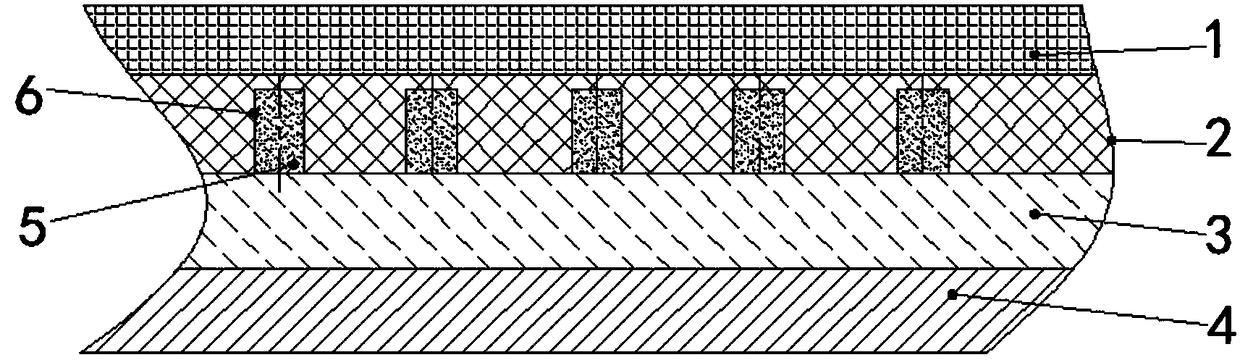

[0025] A method for preparing heat-insulating, sound-insulating, and shock-absorbing fiber felts, comprising an XPE layer 1, a heat sink layer 2, a composite layer 3, and a damping sound-insulating felt 4; the XPE layer 1 is placed on the inner surface of the present invention, with a thickness of 1 to 2 mm , play the role of heat insulation, cushioning, sound absorption, molding, oil resistance, acid resistance, non-toxic and tasteless, energy saving and environmental protection;

[0026] The heat sink layer 2 is an aluminum alloy heat sink, located on the outer surface of the XPE layer 1, with a thickness of 3-4 mm. Aluminum alloy is widely used and low in cost. The effect of using aluminum alloy as a heat sink is better than that of other alloy heat sinks. Experiments have shown that when the thickness of the aluminum alloy is 3 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com