Preparation method of graphene dispersing liquid

A technology of graphene dispersion liquid and graphite, which is applied in the preparation of graphene dispersion liquid and high-quality graphene dispersion liquid. It can solve the problems of uneven graphene dispersion liquid, complex production process and high cost, and achieve easy mass production , The production process is simple and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The green and environment-friendly method for preparing high-quality graphene dispersion involved in this embodiment includes three process steps of preparation of dispersant solution, primary high-shear liquid phase exfoliation and secondary high-pressure exfoliation:

[0013] (1) Preparation of dispersant solution: 1 g of sodium lauryl sulfate dispersant was added to 1000 g of deionized water solvent, fully dissolved to obtain dispersant solution.

[0014] (2), a high-shear liquid phase exfoliation: 10g of graphite raw material flake graphite is added to the dispersant solution prepared in step (1), and then ball milling is carried out by a ball mill, and a high-shear is carried out under the action of a high shear force. The exfoliated graphite slurry was obtained by cutting liquid phase exfoliation.

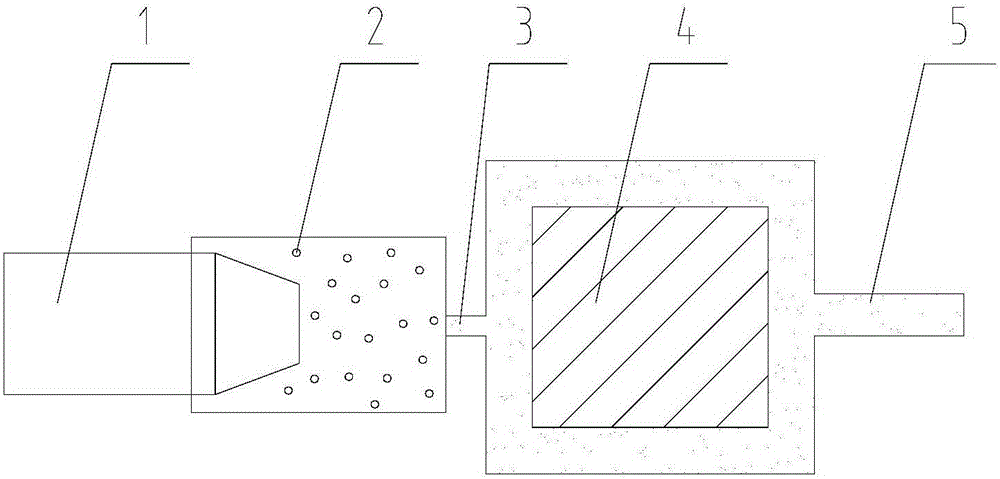

[0015] (3), secondary high-pressure stripping: carried out in the secondary high-pressure stripping system, first apply a pressure of 100 MPa to the graphite slurry 2 ...

Embodiment 2

[0017] The green and environment-friendly method for preparing high-quality graphene dispersion involved in this embodiment includes three process steps of preparation of dispersant solution, primary high-shear liquid phase exfoliation and secondary high-pressure exfoliation:

[0018] (1), preparation of dispersant solution: 2g sodium dodecylbenzenesulfonate dispersant is added in 1000g N-N-dimethylformamide solvent, fully dissolved to obtain dispersant solution;

[0019] (2), a high-shear liquid phase exfoliation: 50g of graphite raw material graphite oxide is added to the dispersant solution prepared in step (1), and then sand-milled by a sand mill, carried out under the action of high shear force A high-shear liquid phase exfoliation to obtain an exfoliated graphite slurry;

[0020] (3), secondary high-pressure peeling: first apply a pressure of 200 MPa to the graphite slurry obtained in step (2), and then make it pass through a slit of 0.5mm width, when the high-pressure f...

Embodiment 3

[0022] The green and environment-friendly method for preparing high-quality graphene dispersion involved in this embodiment includes three process steps of preparation of dispersant solution, primary high-shear liquid phase exfoliation and secondary high-pressure exfoliation:

[0023] (1), preparation of dispersant solution: 10g sodium dodecylbenzenesulfonate dispersant is added in 1000g tetrahydrofuran solvent, fully dissolved to obtain dispersant solution;

[0024] (2), a high-shear liquid phase exfoliation: add 100g of graphite raw material expandable graphite to the dispersant solution prepared in step (1), then carry out high-speed stirring treatment by a high-speed mixer, and carry out under the action of high shear force A high-shear liquid phase exfoliation to obtain an exfoliated graphite slurry;

[0025] (3), secondary high-pressure peeling: first apply a pressure of 150MPa to the graphite slurry obtained in step (2), and then make it pass through a slit of 0.3mm wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com