Method for preparing carbon nanoparticle/two-dimensional layered titanium carbide composite material

A carbon nanoparticle, two-dimensional layered technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of many surface defects, single material characteristics, small layer spacing, etc., to achieve The reaction is controllable, the preparation process is simple, and the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

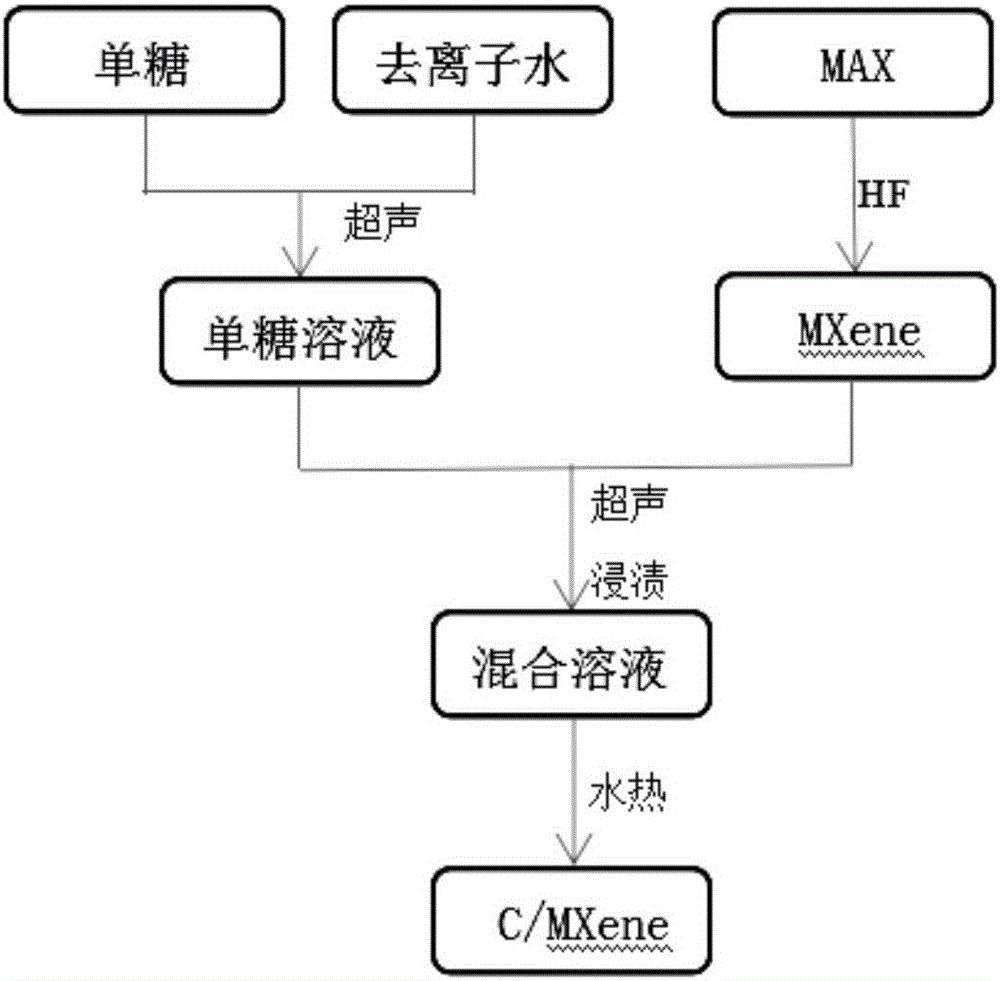

[0026] This embodiment includes the following steps:

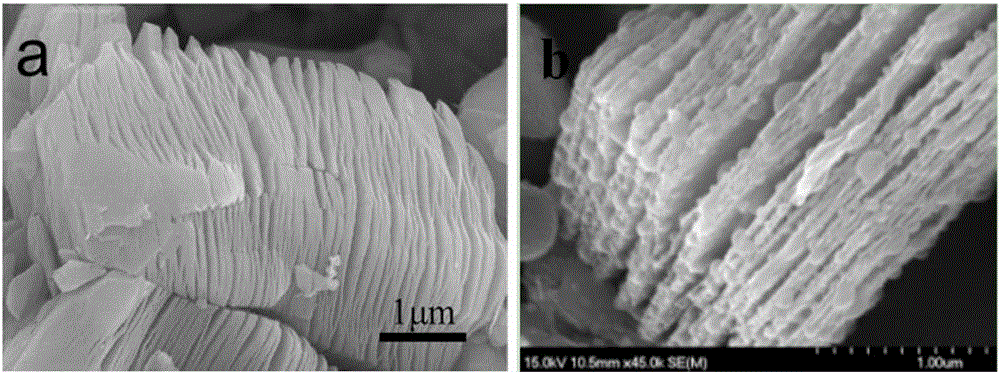

[0027] (1) Weigh 10g Ti 3 AlC 2 The ceramic powder is submerged in 200ml of 40wt% HF solution with magnetic stirring at room temperature for 80 hours; the resulting solution is washed with deionized water until the pH is about 7, filtered into a solid powder, and vacuum-dried at 80°C for 40 hours to obtain MXene (Ti 3 C 2 )nanomaterials. It looks like figure 2 (a) shown.

[0028] (2) Dissolve 1.26g of glucose in 70ml of deionized water and disperse ultrasonically for 5 hours to obtain a monosaccharide solution; 0.63g of the two-dimensional layered material MXene (Ti 3 C 2 ) into the prepared glucose solution, ultrasonically dispersed for 24 hours, and vacuum impregnated for 10 hours;

[0029] (3) Place the impregnated solution in a hydrothermal reactor and react at 180°C for 6 hours, and the filling degree of the inner tank of the reactor is 60% to 80%;

[0030] (4) The obtained product was centrifugally washed w...

Embodiment 2

[0032] This embodiment includes the following steps:

[0033] (1) Weigh 1g Ti 2 AlC ceramic powder, immersed in 10ml of 10wt% HF solution with magnetic stirring at 40°C for 10h; wash the resulting solution with deionized water until the pH is about 7, filter it into a solid powder, and dry it in vacuum at 40°C for 8h. That is to get MXene(Ti 2 C) Nanomaterials.

[0034] (2) Dissolve 5 g of glucose in 30 ml of deionized water, disperse ultrasonically for 0.5 h to obtain a glucose solution, and 0.5 g of the two-dimensional layered material MXene (Ti 2 C) adding to the prepared glucose solution, ultrasonically dispersing for 0.5h, and vacuum impregnating for 4h;

[0035] (3) Place the impregnated solution in a hydrothermal reaction kettle and react for 10 hours at 150° C.; the filling degree of the inner tank of the reaction kettle is 60% to 80%;

[0036] (4) The obtained product was centrifugally washed with deionized water until the pH value of the solution was about 7, and...

Embodiment 3

[0038] This embodiment includes the following steps:

[0039] (1) Weigh 20g Ti 3 AlC 2 The ceramic powder is immersed in 400ml of 30wt% HF solution with magnetic stirring at 65°C for 120h; the resulting solution is washed with deionized water until the pH is about 7, filtered into a solid powder, and vacuum-dried at 60°C for 24h. Get MXene (Ti 3 C 2 )nanomaterials.

[0040] (2) Dissolve 4 g of fructose in 30 ml of deionized water, and disperse it ultrasonically for 2 hours to obtain a fructose solution. Add 1 g of the two-dimensional layered material MXene (Ti 3 C 2 ) into the prepared fructose solution, ultrasonically dispersed for 10 hours, and vacuum impregnated for 2 hours;

[0041](3) Place the impregnated solution in a hydrothermal reaction kettle and react for 20 hours at 220°C; the filling degree of the inner tank of the reaction kettle is 60% to 80%;

[0042] (4) The obtained product was centrifugally washed with deionized water until the pH value of the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com