Method using rheological phase reaction method to synthesize flower-ball-like mesoporous alumina

A rheological phase and flower-shaped technology, applied in the field of mesoporous alumina preparation, can solve the problems of high preparation cost, unfavorable large-scale production of mesoporous alumina, cumbersome steps, etc., and achieve the effect of facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

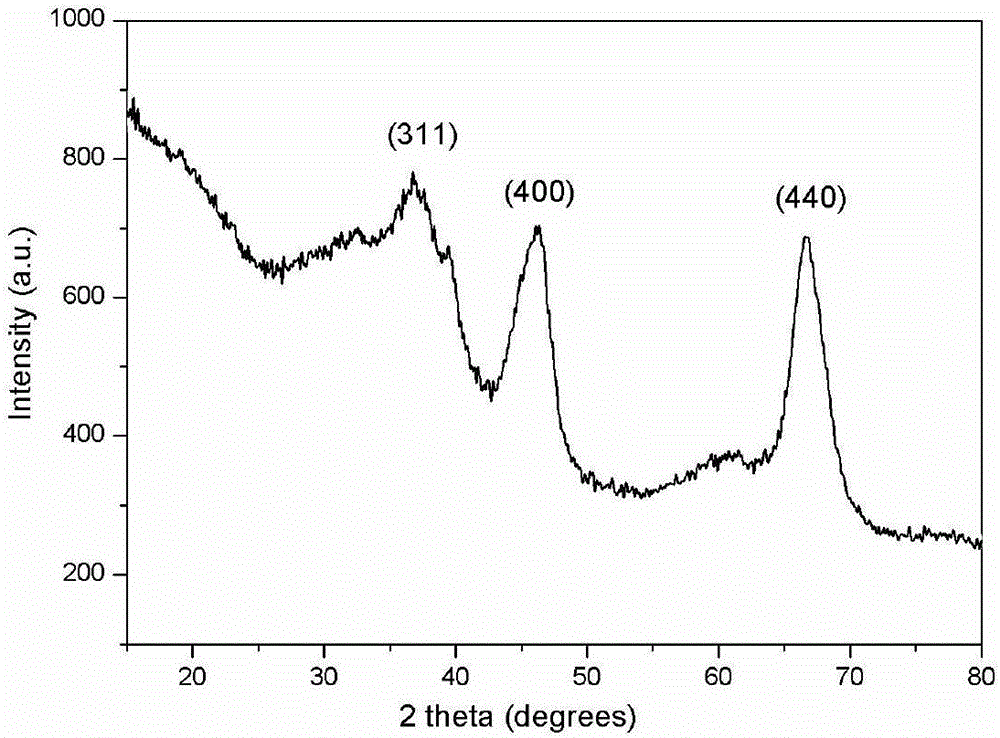

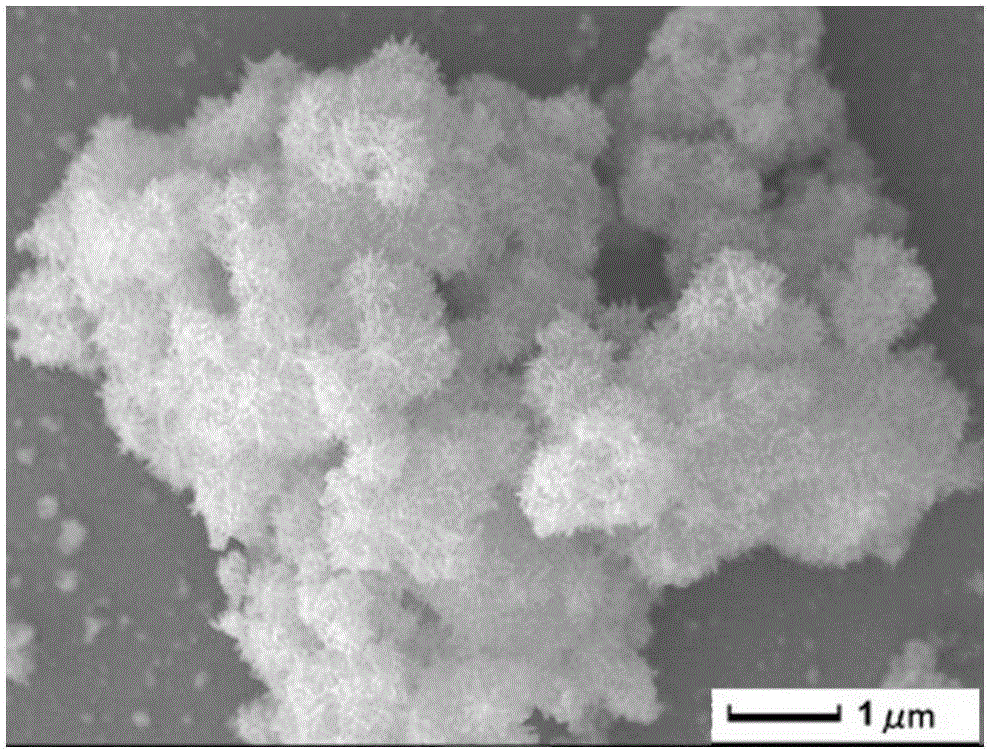

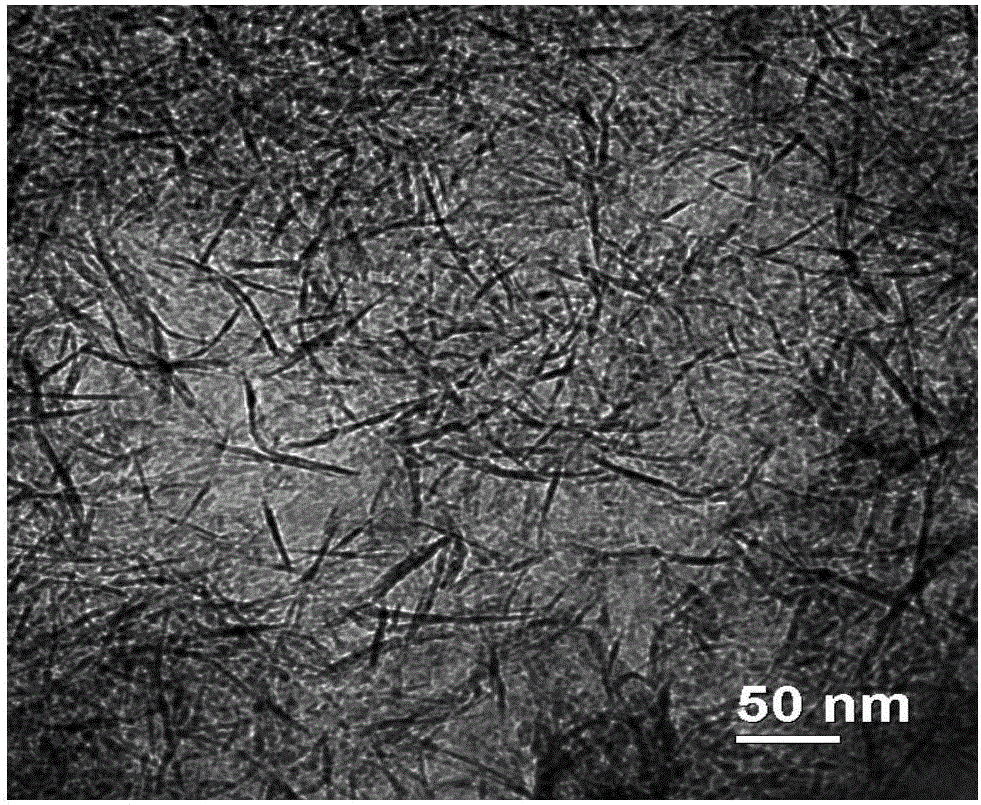

[0023] Take by weighing 1.08g analytical pure aluminum isopropoxide, 0.026g sodium cholate and 0.026g La (NO 3 ) 3 •6H 2 Grind O powder in a mortar, fully grind it uniformly, add 2.0g of ethanol-water mixed solvent (the volume ratio of the two is 1:1) to adjust to a rheological state, then transfer it to a 20mL reactor, seal it, and keep it warm at 100°C After 24 hours, after natural cooling, a white dry gel was obtained. The dry gel was moved to a tube furnace at 550 ° C for 4 hours, the heating rate was 1 ° C / min, and naturally cooled to room temperature to obtain a white powder product. like figure 1 The product shown was identified as γ-Al by X-ray powder diffraction 2 o 3 ;from figure 2 , 3 The morphology analysis of scanning electron microscope and transmission electron microscope shows that the sample is a curd-like layered structure assembled from nanosheets with a thickness of less than 10 nm, and the curd particle size is about 600 nm. Figure 4 N 2 -Adso...

Embodiment 2

[0025] Take by weighing 1.08g analytical pure aluminum isopropoxide, 0.104g sodium cholate and 0.069gLa (NO 3 ) 3 •6H 2 Grind O powder in a mortar, fully grind it uniformly, add 2.0g of ethanol-water mixed solvent (the volume ratio of the two is 1:1) to adjust to a rheological state, then transfer it to a 20mL reactor, seal it, and keep it warm at 100°C After 24 hours, after natural cooling, it was taken out to obtain a white dry gel. The dry gel was moved to a tube furnace at 550 ° C for 4 hours, the heating rate was 1 ° C / min, and naturally cooled to room temperature to obtain a white powder product. The product was identified as γ-Al by X-ray powder diffraction 2 o 3 ; From the morphology analysis of the scanning electron microscope, it can be seen that the sample is a curd cluster, and the curd particle size is about 800 nm; from N 2 - The adsorption-desorption isotherm shows that the mesoporous γ-Al prepared by this implementation method 2 o 3 The specific surfac...

Embodiment 3

[0027] Weigh 2.00g analytically pure Al(NO 3 ) 3 •9H 2 O, 0.104g sodium cholate and 0.026gLa (NO 3 ) 3 •6H 2 Grind O powder in a mortar, fully grind it uniformly, add 2.0g of ethanol-water mixed solvent (the volume ratio of the two is 1:1) to adjust to a rheological state, then transfer it to a 20mL reactor, seal it, and keep it warm at 100°C After 24 hours, after natural cooling, it was taken out to obtain a white dry gel. The dry gel was moved to a tube furnace at 550 ° C for 4 hours, the heating rate was 1 ° C / min, and naturally cooled to room temperature to obtain a white powder product. The product was identified as γ-Al by X-ray powder diffraction 2 o 3 ; From the morphology analysis of the scanning electron microscope, it can be seen that the sample is a curd-shaped cluster, and the curd particle size is about 300 nm; from N 2- The adsorption-desorption isotherm shows that the mesoporous γ-Al prepared by this implementation method 2 o 3 The specific surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com