Extraction agent and method for processing wastewater in hydroxyquinoline production through extraction agent

A treatment method and extraction agent technology are applied in the field of extraction agent and the use of the extraction agent to treat wastewater in the production of hydroxyquinoline, which can solve the problems of great harm to the environment and human beings, environmental pollution, low corrosiveness and the like, and achieve suitable The effect of popularization and use in a large range, simple operation and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

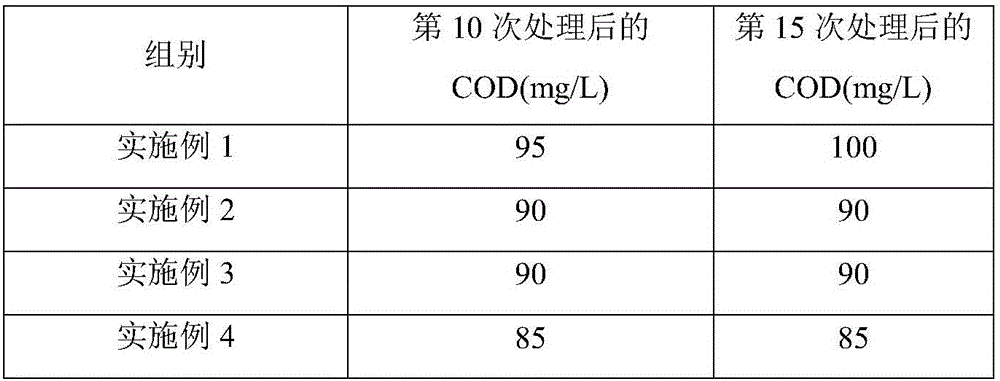

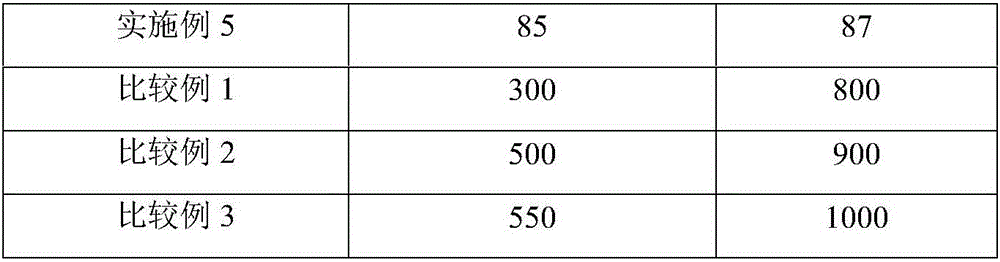

Examples

Embodiment 1

[0037] Process steps for treating the waste water produced in the production of hydroxyquinoline:

[0038] 1) Preparation of extraction agent: trioctylamine 10kg, n-octanol 50kg, sulfonated kerosene 20kg;

[0039] 2) Adjust the pH, use industrial sulfuric acid to adjust the wastewater between 0.85-0.95, add the extractant to stir and separate the layers to obtain the extraction layer and the water layer, adjust the pH of the water layer to between 6-9, and detect the COD of the water layer, After testing, the COD is below 80mg / L, and it will be discharged after passing the test;

[0040] 3) stripping, mixing and stirring the extraction layer with sodium carbonate solution for stripping, reclaiming the extractant in the stripping layer after layering for reuse.

Embodiment 2

[0042] Process steps for treating the waste water produced in the production of hydroxyquinoline:

[0043] 1) Preparation of extraction agent: trioctylamine 20kg, n-octanol 30kg, sulfonated kerosene 50kg;

[0044] 2) Adjust the pH, use industrial sulfuric acid to adjust the waste water between 0.85-0.95, add the extractant to stir and layer to obtain the extraction layer and the water layer, the mass ratio of the waste water to the extractant is 5:1, the stirring rate is 100rad / min, stir The temperature was controlled at 30°C, and then the pH of the water layer was adjusted to 6-9. According to the proportion of 1wt%, activated carbon was added for decolorization, stirred for 20 minutes, and then suction filtered to obtain a transparent and colorless liquid, and COD was detected. After testing the COD is below 80mg / L, it will be discharged after passing the test, and the used activated carbon will be added to the coal-fired boiler for incineration;

[0045] 3) Back extraction...

Embodiment 3

[0047] Process steps for treating the waste water produced in the production of hydroxyquinoline:

[0048] 1) Preparation of extraction agent: trioctylamine 12kg, n-octanol 32kg, sulfonated kerosene 40kg;

[0049] 2) Adjust the pH, use industrial sulfuric acid to adjust the waste water between 0.85-0.95, add the extractant to stir and layer to obtain the extract layer and the water layer, the mass ratio of waste water to extractant is 5:2, the stirring rate is 50rad / min, stir The temperature is controlled at 20°C, and then the pH of the water layer is adjusted to between 6-9. According to the proportion of 2wt%, activated carbon is added for decolorization, the temperature is around 20°C and stirred for 30 minutes, and then filtered by suction to obtain a transparent and colorless liquid. And detect COD. After testing, the COD is below 80mg / L, and it is discharged after passing the test. The activated carbon after use is added to the coal-fired boiler for incineration;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com